2026 Best Practices for Plastic Machining Techniques?

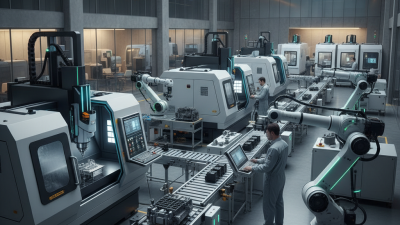

In the realm of manufacturing, plastic machining plays a vital role. This technique shapes various products and components. As industries evolve, so do machining methods. Adopting best practices in plastic machining is essential for efficiency and quality.

Effective plastic machining requires precision. Different plastics behave uniquely under machining processes. Knowing these differences can lead to better outcomes. Challenges often arise in material selection and tool management. Many operators face issues, such as tool wear and surface finish imperfections.

Industries must prioritize advanced techniques and training. Understanding the specifics of each project can enhance results. Mistakes in plastic machining can be costly. Continuous improvement and learning from errors are crucial. Embracing best practices can transform operations, making them more sustainable and competitive.

Overview of Plastic Machining Techniques

Plastic machining is a critical process in various industries. It encompasses multiple techniques like milling, turning, and drilling. These methods allow the production of precision components. One report by the Society of Plastics Engineers indicates that machining plastic can reduce waste by 30%. This efficiency is vital in today's manufacturing landscape.

However, challenges exist in plastic machining. The specifics of each technique vary based on the type of plastic used. For instance, machining harder plastics often leads to wear on tools. A study noted that tool wear can increase cycle times by 15%, impacting overall productivity. Enhancing tool life and selecting the right machining parameters are crucial for optimal outcomes.

Understanding the thermal properties of plastics is also essential. Plastics can deform at high temperatures. This factor can complicate machining processes. A survey found that 40% of professionals identified thermal issues as a significant concern. Continuous learning and adaptation in techniques are necessary. Reflecting on these challenges can lead to better practices in the future.

2026 Best Practices for Plastic Machining Techniques

| Technique | Description | Applications | Advantages | Challenges |

|---|---|---|---|---|

| CNC Machining | Computer Numerical Control machining used for precise shapes and sizes. | Automotive, Aerospace, Medical Devices | High precision, repeatability, and automation possibilities. | Requires skilled operators and maintenance of equipment. |

| Injection Molding | Forming methodology where melted plastic is injected into molds. | Consumer Products, Electronics, Toys | High production rates, complex shapes possible. | Initial mold costs can be high, less flexibility in design changes. |

| Laser Cutting | Using lasers to cut materials with high precision. | Signage, Prototyping, Custom Parts | Minimal material waste and high accuracy. | Heating of material can affect properties, not suited for all plastics. |

| 3D Printing | Additive manufacturing to create parts layer by layer. | Prototyping, Custom Tools, Low Volume Production | Flexibility in design, complex geometries easily achievable. | Slower than traditional methods, surface finish may require post-processing. |

| Thermoforming | Heating plastic sheets and forming them over a mold. | Packaging, Bins, Display Components | Cost-effective for low to medium volume production. | Limited to specific thicknesses and shapes. |

Key Materials Used in Plastic Machining

When it comes to plastic machining, choosing the right materials is critical.

Plastics such as acrylic, polycarbonate, and nylon are commonly used for various applications.

Each material has unique properties that make it suitable for specific tasks.

For example, acrylic is often preferred for transparent components due to its clarity and UV resistance.

However, it can shatter more easily than other materials.

Polycarbonate, on the other hand, offers durability and impact resistance.

It is useful in applications that require strength. Yet, polycarbonate can scratch easily. Maintenance routines must be considered.

Nylon provides excellent wear resistance, making it a common choice for gears and bearings.

However, it absorbs moisture, which can impact its dimensional stability.

These materials all present challenges in machining.

Techniques must adapt to each type's unique characteristics.

It's important to reflect on machining practices and improve efficiency.

Sometimes, even with the best materials, flaws can occur during production.

A careful evaluation of processes can lead to better outcomes in plastic machining projects.

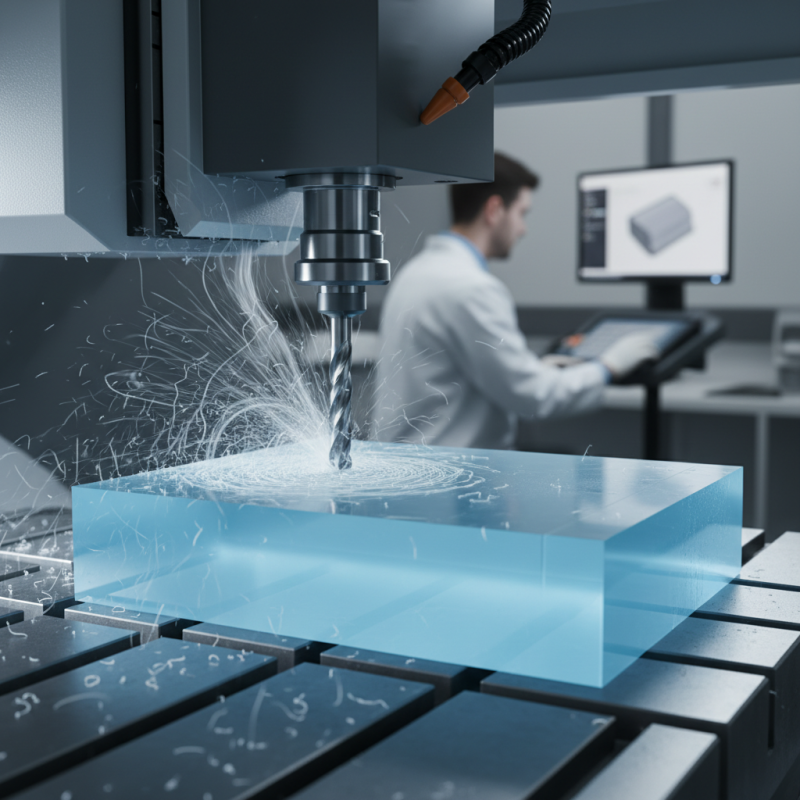

Essential Tools and Equipment for Machining Plastics

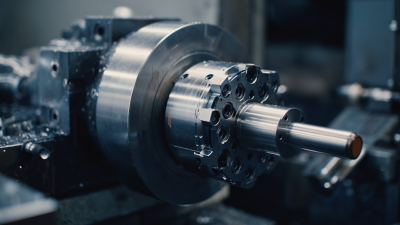

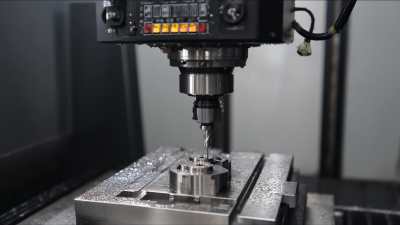

When machining plastics, the right tools are essential. Standard equipment includes milling machines, lathes, and CNC routers. These machines help shape and cut plastic with precision. It's crucial to use the correct cutting tools. Options like HSS and carbide inserts are common. Each option has its advantages and disadvantages. It costs more to replace carbide tools, yet they last longer.

Cooling systems are often overlooked. Maintaining the right temperature can prevent melting or warping. A constant flow of coolant helps manage heat effectively. The choice of coolant can also impact the finish quality. Some materials react differently to various coolants. Testing might be necessary to find the optimal solution.

Lastly, proper clamping techniques improve safety and accuracy. Many operators underestimate the importance of secure workpieces. If a piece isn’t held firmly, it can lead to errors or accidents. It’s a simple detail that can cause major issues. Regularly reviewing machining setups can help identify these pitfalls. Continuous reflection on processes is key to mastering plastic machining.

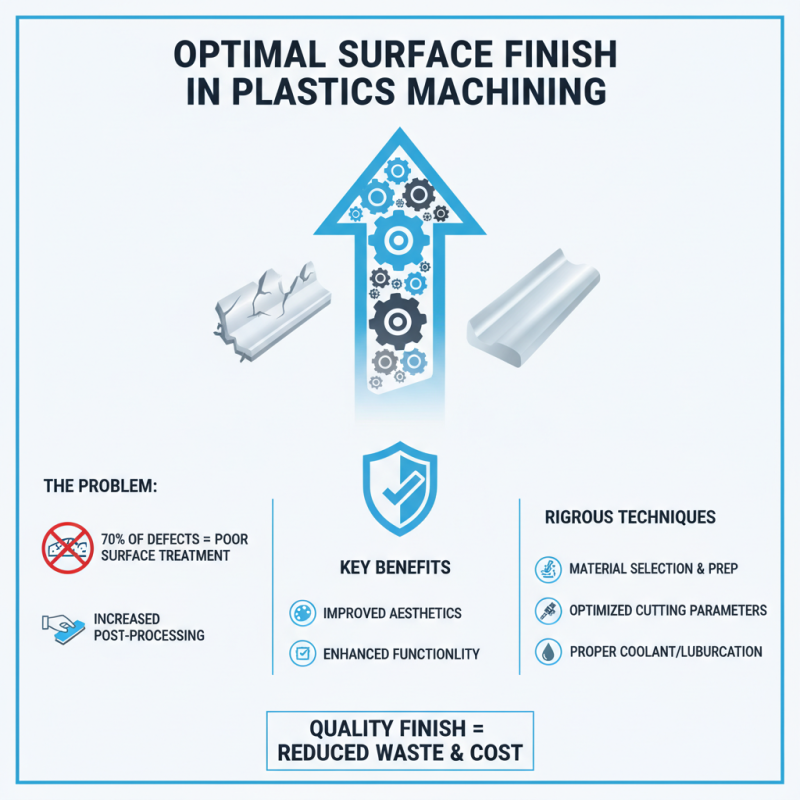

Best Practices for Surface Finish in Plastic Machining

Achieving an optimal surface finish in plastic machining is a critical aspect of the manufacturing process. According to recent industry reports, nearly 70% of machining defects stem from inadequate surface treatments. This highlights the need for rigorous techniques. A well-finished surface improves aesthetics and functionality, reducing the need for post-processing.

One effective approach is using a combination of appropriate tool materials and cutting parameters. For instance, carbide tools often yield better finishes than high-speed steel. However, operators must balance speed and feed rate to avoid surface imperfections. Reports show that a feed rate that’s too high can lead to increased tool wear and poor finishes. It’s a common mistake many make without realizing it.

Another frequent oversight is neglecting proper cooling methods during machining. Insufficient cooling can lead to thermal deformation of the plastic, affecting the final surface quality. Studies indicate that just a slight increase in temperature can alter properties, highlighting the need for adequate cooling systems. Operators need to evaluate their processes critically, as small changes can lead to significant improvements.

Common Challenges and Solutions in Plastic Machining Techniques

Plastic machining presents distinct challenges.

Deformation during machining is one issue. Plastics can warp under heat, impacting dimensions.

Controlling temperature is crucial. Use coolants or optimized feed rates to maintain stability.

Another challenge is burr formation.

Burrs can compromise part quality. Regular tool maintenance can reduce this issue.

Choosing the right tool geometry also plays a key role. It can effectively minimize formation and improve finish.

Lastly, material selection is vital.

Different plastics behave uniquely. Some are more prone to cracking or tearing.

Understanding these differences helps in planning the process.

Testing various materials ensures better outcomes, but it requires time and effort.

Continuous reflection on techniques is necessary to enhance results.

Related Posts

-

Understanding CNC Controllers: Revolutionizing Precision Manufacturing with 30% Higher Efficiency

-

What is Manufacturing Machines and How They Transform Production Processes

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

-

How to Optimize Plastic CNC Machining for Better Precision and Efficiency

-

Top 10 CNC Machining Centers: Which One is Best for Your Needs?

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections