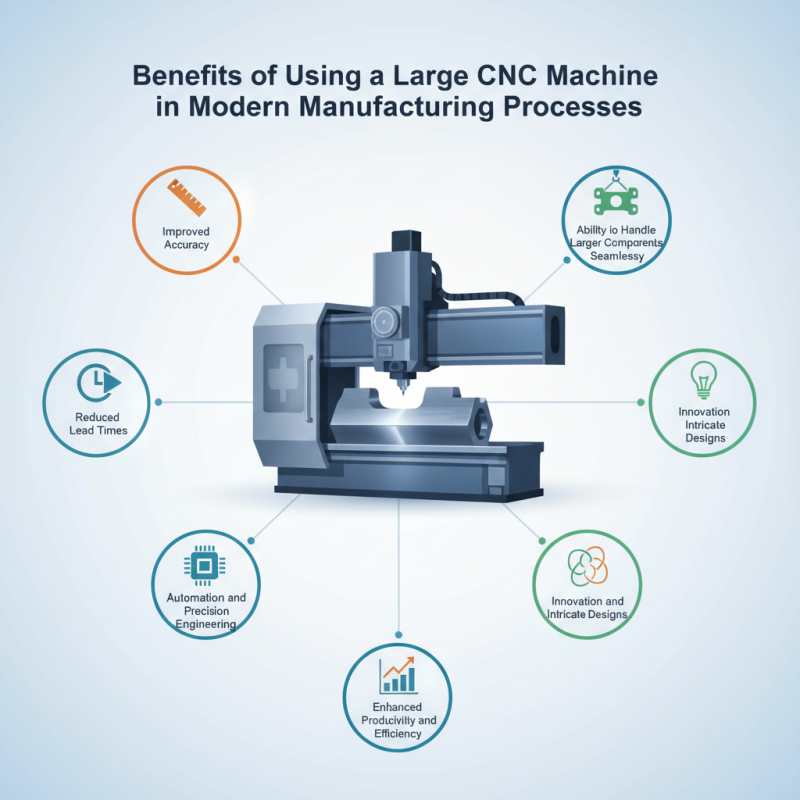

Benefits of Using a Large CNC Machine in Modern Manufacturing Processes

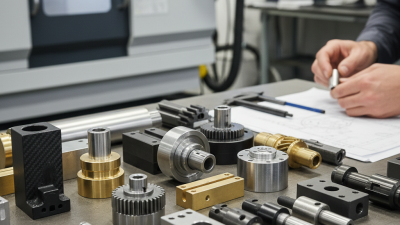

In the rapidly evolving landscape of modern manufacturing, the adoption of advanced technologies plays a crucial role in enhancing productivity and precision. A key player in this transformation is the large CNC machine, which has become increasingly vital in various industrial applications. These machines offer unparalleled capabilities in terms of size, complexity, and efficiency, making them an indispensable asset for manufacturers striving to maintain competitiveness in today’s market.

The benefits of utilizing a large CNC machine extend beyond mere production volume; they encompass improved accuracy, reduced lead times, and the ability to handle larger components seamlessly. With such advanced machinery, manufacturers can execute intricate designs and cuts that were previously challenging or impossible with traditional methods. As a result, embracing large CNC technology not only streamlines the manufacturing process but also fosters innovation, enabling businesses to explore new product possibilities and enhance their overall operational effectiveness.

Ultimately, the integration of large CNC machines into manufacturing processes signifies a shift towards embracing automation and precision engineering. As industries continue to demand higher efficiency and quality, the role of these machines will undoubtedly grow, shaping the future of how products are designed and produced.

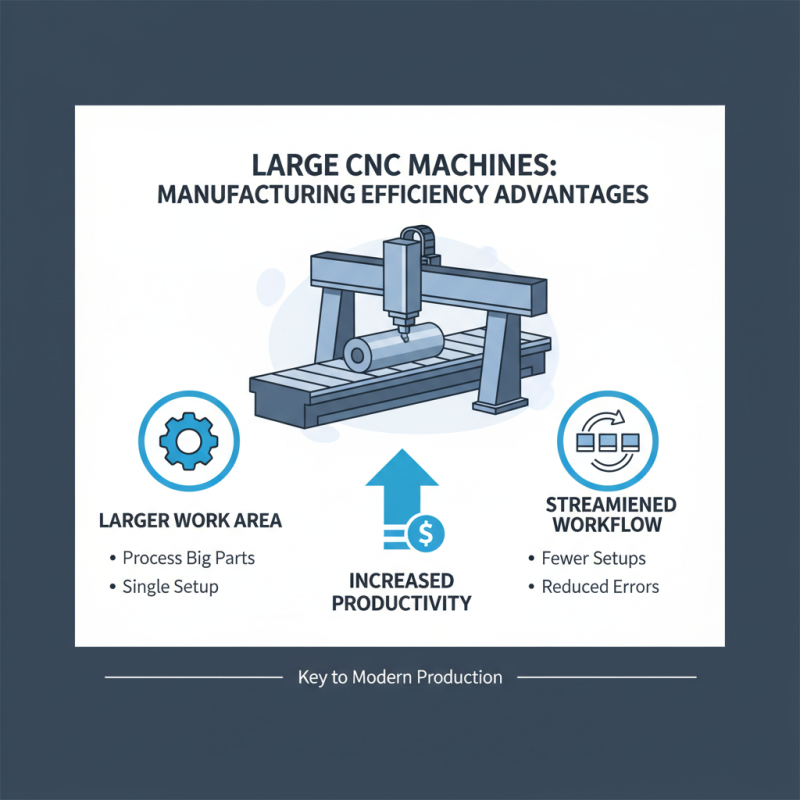

Advantages of Large CNC Machines in Manufacturing Efficiency

The advantages of large CNC machines in manufacturing efficiency are manifold, making them a vital asset in modern production environments. Firstly, their expansive working areas allow for the processing of larger materials and components in a single setup, significantly reducing the need for multiple workstations and setups. This capability not only streamlines the workflow but also minimizes the chances of inaccuracies that often arise from repositioning or re-clamping parts between operations.

Moreover, large CNC machines enhance precision and consistency throughout the manufacturing process. With advanced control systems and automation, they can produce intricate designs with exceptional repeatability. This reliability is critical in industries where precision is paramount, such as aerospace and automotive manufacturing, where even the slightest deviation can lead to significant complications. The integration of software advancements further facilitates complex geometries, ultimately leading to shorter lead times and increased overall productivity.

Additionally, the scalability of large CNC machines offers manufacturers the flexibility to meet varying production demands. As market needs change, companies can easily adapt their operations by leveraging the capabilities of large CNC machines to handle larger batches without sacrificing quality or efficiency. This adaptability not only boosts competitiveness in a fast-paced market but also promotes more sustainable manufacturing practices by optimizing resource use and minimizing waste.

Enhanced Precision and Accuracy in Large Scale Production

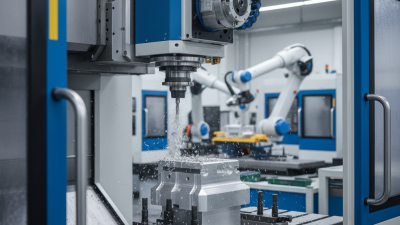

The integration of large CNC machines in modern manufacturing processes greatly enhances precision and accuracy, crucial for large-scale production. These machines, equipped with advanced technology and robust design, enable manufacturers to produce parts with tight tolerances consistently. This level of precision is vital in industries where even minute variations can lead to inefficiency or product failure. By minimizing human error through automation, large CNC machines ensure that products meet exact specifications, which is particularly beneficial for sectors such as aerospace, automotive, and electronics.

Furthermore, the scale of production achievable with large CNC machines allows for improved efficiency without sacrificing quality. The ability to handle vast materials and perform complex operations simultaneously means that manufacturers can optimize their workflows and reduce lead times. This not only accelerates the production cycle but also enhances resource management by cutting down on material waste. As the demand for high-quality, precision-engineered components continues to rise, large CNC machines stand at the forefront, making precision and accuracy in large-scale production a reality for manufacturers around the world.

Reduction of Production Time with Large CNC Technology

The introduction of large CNC machines into modern manufacturing processes has led to significant reductions in production time, benefiting companies across various industries. According to a report by the International Federation of Robotics, the integration of advanced CNC technology has enabled manufacturers to slash production times by up to 50%. This efficiency gains stem from the machines’ ability to automate complex tasks, allowing for continuous operation and minimizing the need for manual intervention.

Furthermore, large CNC machines offer greater precision and scale, which enhances productivity. A study by the National Institute of Standards and Technology highlighted that the enhanced operational speed and higher machining accuracy of large CNC machines can lead to a decrease in waste material by as much as 30%. This not only contributes to faster production cycles but also facilitates a more sustainable manufacturing process, as less scrap means lower material costs and reduced environmental impact. As businesses continue to adopt large CNC technology, the potential for improved economies of scale becomes increasingly apparent, positioning them for greater competitiveness in the global market.

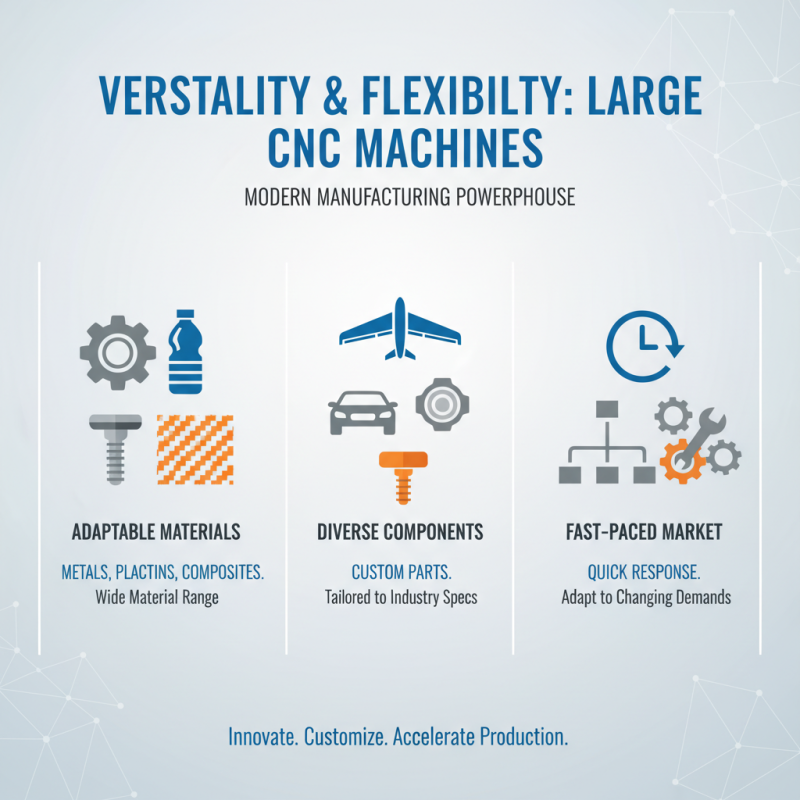

Versatility and Flexibility in Manufacturing Applications

The versatility and flexibility offered by large CNC machines play a crucial role in modern manufacturing processes. These machines can handle a wide array of materials, from metals and plastics to composites, allowing manufacturers to produce diverse components that meet varying industry specifications. This adaptability is essential in today’s fast-paced market, where companies must respond quickly to changing demands and customize their products to suit different applications.

In addition to material versatility, large CNC machines can accommodate complex geometries and intricate designs with high precision. This capability enables manufacturers to tackle a broad range of projects, from simple parts to elaborate assemblies, without the need for multiple setups or different machines. As a result, production efficiency is significantly enhanced, reducing both lead times and operational costs. Furthermore, the programmability of CNC machines allows for quick adjustments and modifications, ensuring that manufacturers can pivot their production techniques as needed to stay competitive in a dynamic landscape.

Cost-Effectiveness of Large CNC Machines in Production Processes

Large CNC machines have become a staple in modern manufacturing due to their significant cost-effectiveness in production processes. The initial investment may seem daunting, yet their ability to streamline operations and increase output can lead to substantial savings over time. These machines often operate with higher precision and speed compared to traditional manufacturing methods, which translates to reduced waste and minimized material costs. As a result, businesses can achieve economies of scale, allowing for more competitive pricing in the market.

Moreover, the versatility of large CNC machines enhances their cost-effectiveness. They can be programmed to perform complex tasks, which reduces the need for multiple machines and operators. This not only lowers labor costs but also optimizes floor space in manufacturing facilities. By consolidating various processes into a single operation, manufacturers can further decrease turnaround times, leading to faster product delivery and improved customer satisfaction. The combined effect of these factors positions large CNC machines as a smart investment for manufacturers aiming to enhance their operational efficiency while maintaining budgetary control.

Benefits of Using a Large CNC Machine in Modern Manufacturing Processes

Related Posts

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

Top 10 CNC Machining Centers: Which One is Best for Your Needs?

-

Why CNC Machine Tools Are Essential for Modern Manufacturing Success

-

10 Essential Tips for Choosing the Right CNC Parts for Your Project

-

Why Precision CNC Machining is Essential for High Quality Manufacturing