2026 Best CNC Machine Working Techniques for Optimal Performance

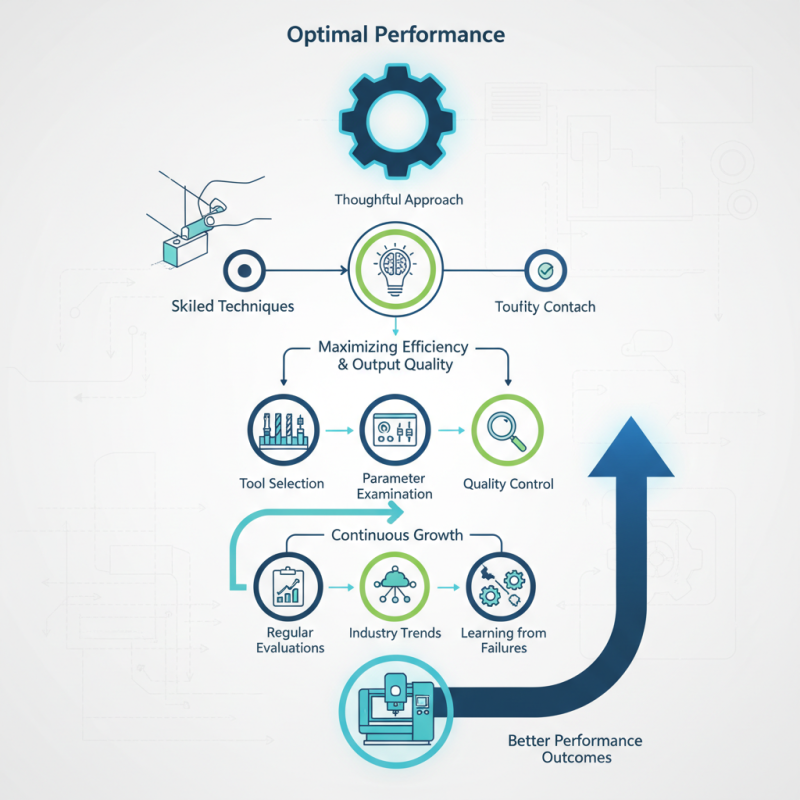

In the world of manufacturing, optimizing performance is crucial. Achieving excellence in CNC machine working requires skilled techniques and a thoughtful approach. With the rise of technology, the methods for maximizing efficiency continue to evolve.

Understanding the intricacies of CNC machine working can be overwhelming. There’s a vast array of techniques to consider. Some may appear effective but yield inconsistent results. For instance, improper tool selection can lead to tool wear or damage. Each parameter must be examined to ensure the highest output quality. Quality control, often overlooked, is essential for maintaining standards.

As we explore the best practices, remember that perfection is elusive. Regular evaluations help identify areas for improvement. Small adjustments in settings can make a significant impact. Engaging with industry trends and learning from failures can enhance our CNC machine working strategies. Adopting a reflective mindset fosters continuous growth and better performance outcomes.

Understanding CNC Machines: The Basics of Operation and Functionality

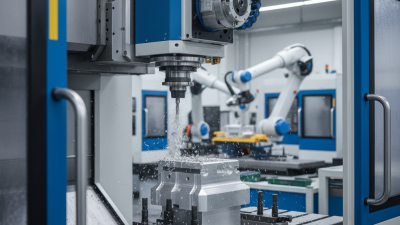

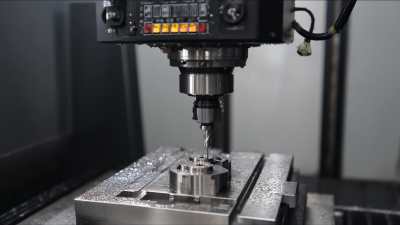

CNC machines have revolutionized manufacturing. They automate processes with precision. Understanding their operation is crucial. These machines use computer programming to control tools like lathes and mills. The accuracy they achieve is remarkable. However, mastering their functionality takes time.

The basics include knowing the components. A CNC machine features a controller, motors, and spindles. Each part plays a vital role. The controller interprets code into movement. Motors drive the tool to cut or shape material. Familiarity with these elements enhances performance.

Mistakes can occur even with advanced technology. Code errors can lead to incorrect cuts. Sometimes, machines need recalibration. Operators must remain vigilant and prepared for troubleshooting. Regular inspections can help maintain optimal functionality. Understanding these details ensures a smoother workflow and better results in the long run.

2026 Best CNC Machine Working Techniques for Optimal Performance

| Technique | Description | Benefits | Common Applications |

|---|---|---|---|

| Toolpath Optimization | Adjusting the CNC toolpath for efficiency and speed. | Reduces machining time and costs. | Milling, Turning |

| Feed Rate Adjustment | Modifying the speed of the tool's movement. | Improved surface finish and tool life. | Drilling, Engraving |

| Cooling Techniques | Using coolant to reduce heat during machining. | Prevents tool wear and part distortion. | Metal Machining, Extrusion |

| Regular Maintenance | Routine checks and servicing of CNC machines. | Enhances reliability and performance. | All CNC Operations |

| Material Selection | Choosing the right material for specific applications. | Optimizes durability and performance. | Construction, Aerospace Components |

Key Techniques for CNC Machining: Maximizing Efficiency and Precision

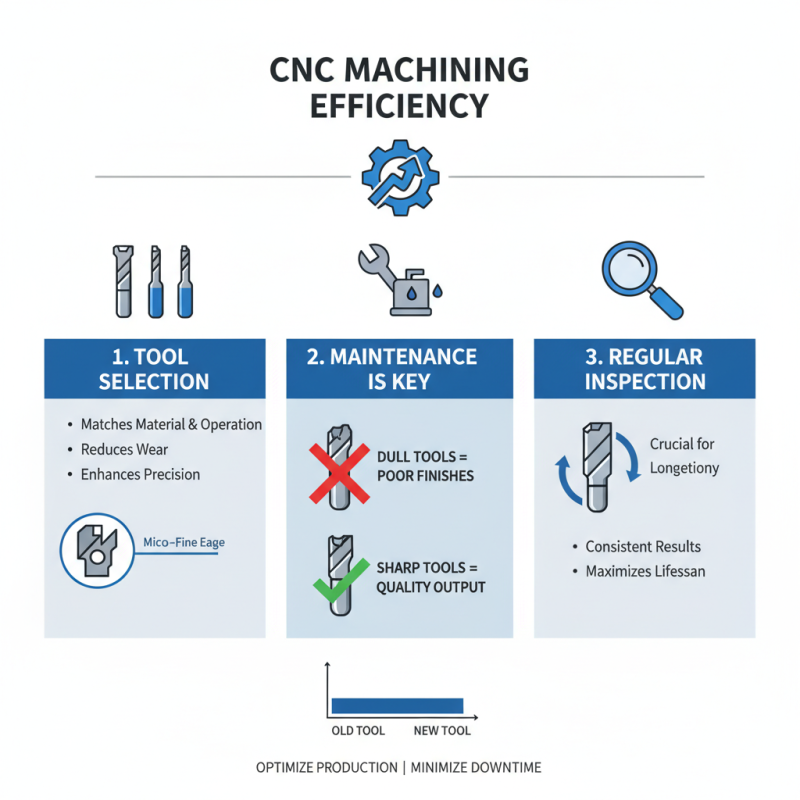

CNC machining has transformed manufacturing processes. To maximize efficiency, one must focus on tool selection. The right tools reduce wear and enhance precision. Dull tools lead to poor finishes. So, regular inspection is crucial. A well-maintained tool extends its lifespan and ensures faithful results.

Another vital technique involves optimizing machining parameters. Feed rates and spindle speeds play a significant role. Too high a feed can cause breakage. With slower speeds, you may sacrifice productivity. Understanding the material is key. Each material has its specific requirements. Testing different settings can reveal better outcomes and prevent costly mistakes.

Lastly, proper setup cannot be overlooked. Even a minor misalignment can lead to inaccuracies. Ensure all measurements are verified before starting. Take the time to double-check setups. It minimizes errors down the line. Documentation of successful setups helps refine future processes. Mistakes can be learning opportunities, leading to improved techniques.

Essential Maintenance Practices for Optimal CNC Machine Performance

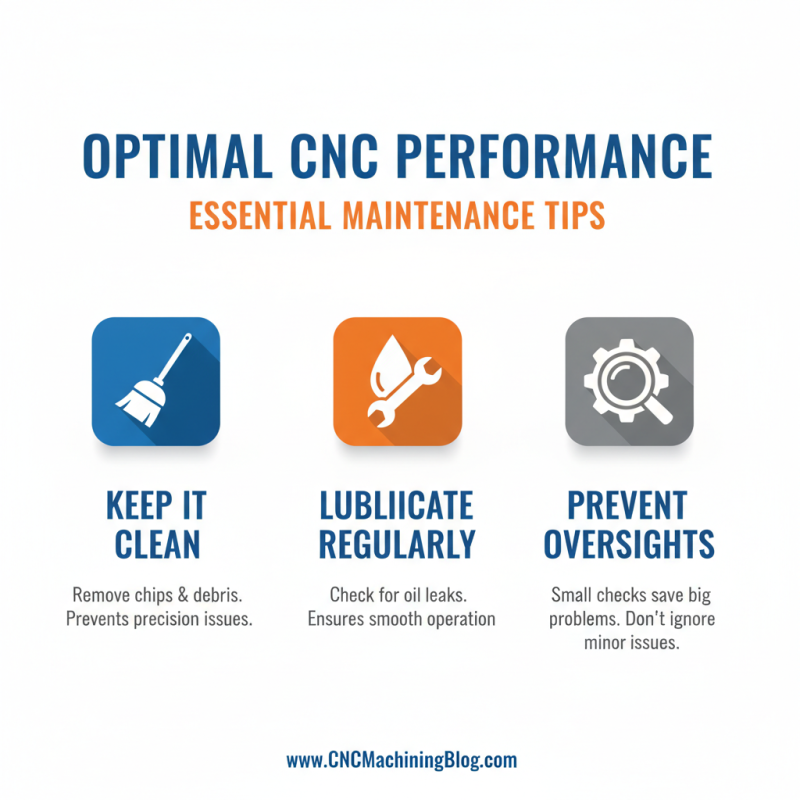

To achieve optimal CNC machine performance, regular maintenance is essential. Ensure the machine is clean and free of debris. Loose chips can affect precision. Check for oil leaks regularly. Lubrication keeps the machine moving smoothly. It’s surprising how often this goes unnoticed. A small oversight can lead to bigger issues.

Inspect all moving parts frequently. Gears and belts should not exhibit any wear. Low-quality components can compromise performance. It's crucial to be vigilant. Sometimes, it’s easy to overlook minor problems until they escalate. Replace damaged parts promptly. Neglect can lead to costly downtime.

Calibration is another key aspect of maintenance. Machines should be checked against standards routinely. Misalignment can drastically increase errors in production. Regular training for operators is vital. They should know how to spot issues ahead of time. This holistic approach to maintenance can enhance machine longevity. Reflecting on these practices may reveal areas for improvement.

Advanced Programming Strategies for Enhanced CNC Machine Outputs

Advanced programming strategies play a crucial role in optimizing CNC machine outputs. Employing G-code effectively can significantly enhance precision. For instance, using subprograms allows repeated actions without reprogramming. This saves time and reduces errors. It’s important to understand the machine's capabilities fully. Testing different codes and modifications can reveal potential improvements.

Consistency in programming is key, yet creativity should not be overlooked. Experimentation with tool paths can lead to innovative results. However, overcomplicating programs might introduce bugs. Simple designs can sometimes yield better outcomes. Feedback loops during production often highlight inefficiencies. Engaging in regular reviews of your programming techniques can reveal areas needing adjustment.

Efficient use of CNC machines requires a balance of technique and adaptability. Each project presents unique challenges. Embracing a mindset of continuous improvement allows for better performance over time. Missteps in programming can offer valuable lessons. Learning from these experiences ultimately leads to higher quality outputs. Focus on refining strategies regularly, as this fosters growth and development in CNC machining practices.

Safety Protocols: Ensuring a Secure CNC Working Environment

CNC machining offers precision but also poses safety challenges. A secure working environment is essential. According to the Occupational Safety and Health Administration (OSHA), about 10% of workers in manufacturing experience injuries annually. Addressing safety must be a priority for reducing these numbers.

Proper training is crucial for CNC operators. A recent industry report shows that companies with regular safety training see a 30% decrease in workplace accidents. Operators should understand machine hazards clearly. Regular inspections of CNC machines can prevent malfunctions that lead to injuries.

**Tip:** Always wear appropriate personal protective equipment (PPE) like gloves and goggles.

Encouraging open communication about safety can foster a proactive culture. Operators should report unsafe conditions without fear. One survey indicated that 45% of employees hesitate to speak up about safety issues. This silence can lead to avoidable accidents.

**Tip:** Implement a safety reporting system.

Developing a comprehensive safety protocol is crucial. It involves not just training, but also maintenance and employee engagement. Everyday practices must reflect a commitment to safety and awareness. Regular drills can help reinforce this mindset.

Related Posts

-

Why CNC Machine Tools Are Essential for Modern Manufacturing Success

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

Top 10 CNC Machining Centers: Which One is Best for Your Needs?

-

10 Essential Tips for Choosing CNC Machine Tools for Your Projects?

-

What is CNC Work and How Does it Benefit Your Manufacturing Process

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections