10 Best CNC Machines for Precision Engineering in 2023

In the rapidly advancing world of precision engineering, selecting the right CNC machine can be a game changer for manufacturers striving to enhance productivity and accuracy. According to Dr. Emily Hartwell, a renowned expert in CNC technology, "The evolution of CNC machines has not only transformed manufacturing processes but has also set new benchmarks for precision that define the future of engineering." As industries continue to innovate, understanding the top CNC machines available in 2023 becomes increasingly crucial for businesses aiming to stay competitive.

This guide delves into the ten best CNC machines that stand out for their reliability, versatility, and performance in precision engineering. By exploring these machines, engineers and manufacturers can make informed decisions that align with their production requirements and quality standards. With the right CNC machine, companies can ensure enhanced operational efficiency while delivering unmatched precision in their projects.

Overview of CNC Machines in Precision Engineering

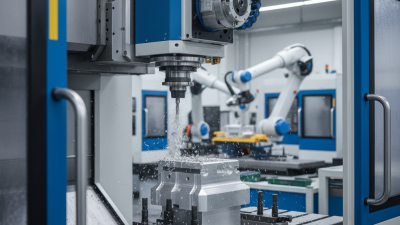

CNC machines play a crucial role in precision engineering, offering unparalleled accuracy and consistency in manufacturing processes. These machines utilize computer numerical control technology to automate the movement of tools and machinery, allowing for complex shapes and intricate designs to be crafted with minimal human intervention. This level of precision is essential in industries such as aerospace, automotive, and medical device manufacturing, where even the slightest deviation can lead to significant issues in performance and safety.

The overview of CNC machines highlights their essential features, including the types of CNC machining processes available, such as milling, turning, and drilling. Each type serves a specific purpose, enabling engineers to select the most appropriate method for their projects. Additionally, advancements in CNC technology, such as 5-axis machining and integrated software solutions, have further enhanced the capabilities of these machines, allowing for higher productivity and faster turnaround times. As precision engineering demands continue to rise, the evolution of CNC machines remains pivotal in meeting the challenges of modern manufacturing environments.

Key Features to Consider When Selecting CNC Machines

When selecting a CNC machine for precision engineering, several key features should be prioritized to ensure optimal performance and accuracy. First and foremost, the machine's rigidity and stability are crucial, as they directly impact the precision of the cuts and the longevity of the equipment. A robust frame and high-quality materials can significantly reduce vibrations during operation, leading to better surface finishes and tighter tolerances.

Another essential aspect to consider is the range of compatible materials. A versatile CNC machine should be able to handle various substrates, from metals to plastics and composites. Furthermore, look for advanced features like multi-axis capabilities, which allow for more complex designs and intricate geometries. Additionally, the machine's software and ease of programming also play a vital role in enhancing efficiency and user-friendliness, enabling operators to execute designs with minimal errors and faster turnaround times. By focusing on these critical features, users can better navigate the selection process and choose a CNC machine that meets their precision engineering needs.

10 Best CNC Machines for Precision Engineering in 2023

Top CNC Machine Brands and Their Specialties

When it comes to precision engineering, the landscape of CNC machines is diverse, with various brands specializing in unique features and capabilities. Some manufacturers focus on producing high-speed machining centers that excel in speed and efficiency, making them ideal for rapid prototyping and high-volume production. These brands leverage advanced technology to enhance precision, ensuring that each machined part meets meticulous specifications required in industries like aerospace and automotive.

On the other hand, there are brands that prioritize versatility, offering CNC machines that can handle a wide range of materials, from metal to composites. These machines often include multi-functional tools and capabilities such as milling, turning, and laser cutting, allowing engineers to execute complex designs with ease. By providing flexible solutions, these manufacturers cater to businesses looking to adapt to various projects and changing market demands without the need for investing in multiple machines.

Additionally, some companies are recognized for their user-friendly interfaces and robust software integration, empowering operators with greater control and customization in their machining processes. Such features are essential for companies aiming to optimize their workflows and reduce training times for employees. This commitment to enhancing user experience plays a crucial role in driving efficiency and meeting precision engineering goals.

Comparative Analysis of the 10 Best CNC Machines for 2023

The comparative analysis of the best CNC machines for precision engineering in 2023 reveals a marked evolution in technology, catering to an increasingly demanding industry. According to a recent market report by Grand View Research, the global CNC machines market is projected to reach USD 118.2 billion by 2025, highlighting a CAGR of approximately 6% from 2019. This growth emphasizes the critical importance of precision and automation in manufacturing processes, which have become essential for enhancing productivity and reducing operational costs.

In our analysis, key features such as accuracy, speed, and versatility have been assessed to determine the most suitable CNC machines for different engineering applications. With the advent of advanced technologies like artificial intelligence and machine learning integrated into CNC operations, new models offer unprecedented levels of precision. A study by Research and Markets indicates that the demand for five-axis CNC machines is surging, driven by their ability to produce complex parts with superior accuracy compared to traditional three-axis counterparts.

The performance metrics of the top machines reflect advancements in rigidity and thermal stability, resulting in improved cutting speeds and longer tool life, which are crucial for maintaining competitive advantage in precision engineering.

Future Trends in CNC Technology for Precision Engineering

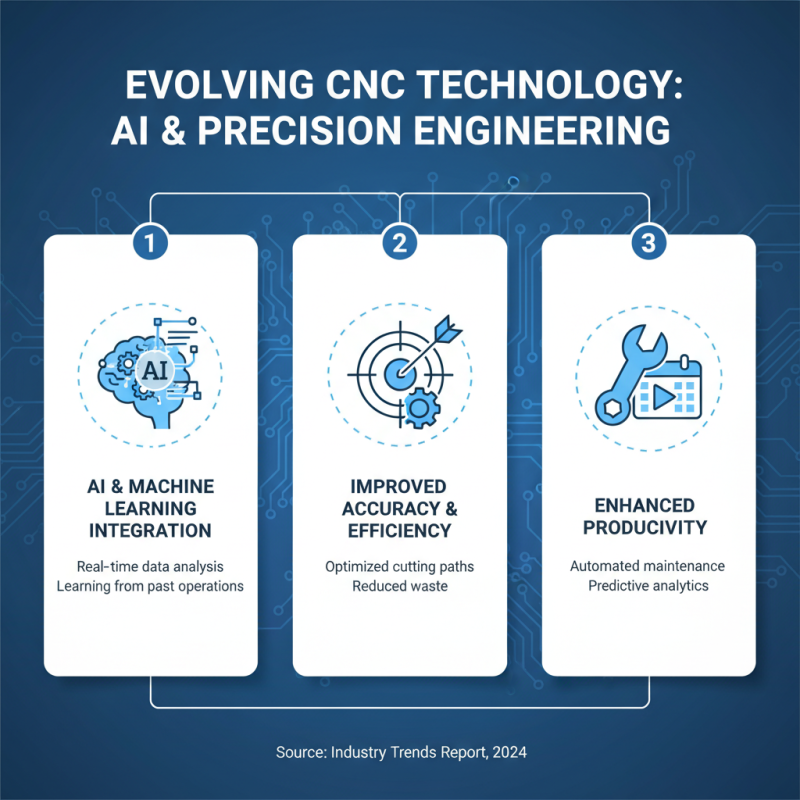

The landscape of CNC technology is continuously evolving, largely driven by advancements in precision engineering. One of the most notable trends is the integration of artificial intelligence (AI) and machine learning into CNC systems. This technological shift enables machines to analyze performance data in real-time, leading to improved accuracy and efficiency in production processes. By learning from past operations, these smart machines can optimize cutting paths, reduce waste, and automate maintenance schedules, which ultimately enhances overall productivity.

Another significant trend influencing CNC technology is the increasing adoption of additive manufacturing alongside traditional subtractive methods. Hybrid systems that combine both processes allow for greater flexibility and complexity in part design. This convergence not only facilitates the production of intricate components but also accelerates prototyping and reduces lead times. As industries seek to produce lightweight and high-strength materials, the integration of CNC milling with additive processes stands to revolutionize precision engineering, making it more agile and responsive to market demands.

Additionally, sustainability is becoming a focal point in CNC advancements. As manufacturers strive to minimize their environmental impact, developments in energy-efficient machines and processes are being prioritized. Innovations such as digital twins, which simulate production processes to identify inefficiencies, are gaining traction. By adopting sustainable practices, companies are not only complying with regulations but also meeting the growing expectations of consumers for eco-friendly products. This commitment to sustainability is set to shape the future of CNC technology, ensuring that precision engineering can thrive in a world that values environmental stewardship.

Related Posts

-

Why CNC Machine Tools Are Essential for Modern Manufacturing Success

-

Top 10 Benefits of Using CNC Turning Machines for Precision Manufacturing

-

Top 10 CNC Machining Centers: Which One is Best for Your Needs?

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques