2026 Best CNC Mill Machine for Precision Engineering?

As the demand for precision engineering continues to grow, the CNC mill machine industry faces both challenges and opportunities. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach $117 billion by 2026, highlighting the integral role these machines play in various sectors. Experts like Dr. James H. Parker, a renowned authority in CNC technology, emphasize that "precision in CNC milling is not just an advantage; it’s a necessity for competitiveness."

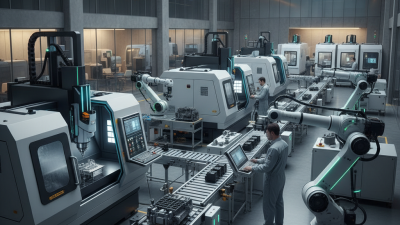

In the quest for the best CNC mill machine, engineers must analyze factors such as accuracy, speed, and versatility. Recent trends indicate a shift towards automation and advanced software integration to enhance efficiency. However, many manufacturers still grapple with outdated equipment and insufficient training. This gap presents a significant hurdle in maximizing the potential of CNC milling technology.

The best CNC mill machine should not only meet current demands but also adapt to emerging technologies. Innovations such as AI-driven controls and real-time feedback systems are paving the way for the future. Yet, many companies are slow to embrace these advancements, risking obsolescence. Balancing traditional craftsmanship with modern technology remains a critical reflection point for the industry.

Overview of CNC Mill Machines for Precision Engineering

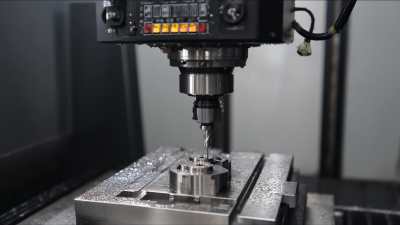

CNC milling machines are essential tools in precision engineering. These machines provide accuracy and efficiency in manufacturing parts for various industries. They can create complex shapes and intricate designs that manual milling simply cannot achieve. The technology behind CNC milling has advanced significantly, offering faster processing speeds and increased reliability.

When choosing a CNC mill machine, engineers must consider several factors. The machine’s build quality is crucial. A solid construction ensures stability during operation, reducing errors. Software compatibility also plays a vital role. Some machines have user-friendly interfaces, making them easier to operate. Others may require extensive training, which can be a barrier for some users.

Moreover, the accuracy of the machine should be closely examined. Many machines boast high precision levels, but this claim can vary. Tolerances are key in engineering. Even a minor deviation can lead to significant issues in the final product. That’s why it’s important to reflect on each machine's specifications carefully. Sometimes, potential users overlook critical details that could affect their workflow.

Key Features to Consider in CNC Milling Machines

When choosing a CNC milling machine, key features are essential for precise engineering. Rigidity is critical. A robust structure minimizes vibrations, ensuring accuracy during operation. Look for machines with solid frames and heavy-duty components. This stability is vital for creating intricate designs.

Another important factor is the spindle speed. A higher speed allows for better material removal rates. However, it may lead to overheating if not well-managed. Cooling systems become crucial here. Proper cooling prevents damage to both the tool and the material. Balanced speed and cooling improve longevity and precision.

Tooling versatility cannot be overlooked. The best machines should support various tools. This flexibility enhances efficiency when switching tasks. Operators may face challenges if a machine lacks this adaptability. Maintaining tool alignment is another concern. Misalignment can lead to costly errors in manufacturing. Regular calibration checks should become routine to mitigate this issue.

Top CNC Mill Machines for Precision Engineering in 2026

In 2026, precision engineering demands CNC mill machines that excel in accuracy and efficiency. The market is full of options that cater to different needs. Some machines focus on speed, while others prioritize stability and precision. When choosing, consider the specific tasks you need to accomplish.

Tips for selecting the right CNC mill:

1. Examine your materials. Different machines handle various materials differently. Test before committing.

2. Check for user friendliness. A complicated interface can slow down your workflow. Simplicity often leads to better results.

3. Look for upgrade potential. Technology evolves. Investing in a machine that can adapt may save money in the long run.

These machines must align with your goals. Pay attention to customer reviews and feedback from users. Sometimes, what looks great on paper may not perform as expected. Don’t rush your decision. Take your time to evaluate your options. Precision engineering requires thoughtful choices.

2026 Best CNC Mill Machines for Precision Engineering

Innovative Technologies in CNC Milling for Enhanced Precision

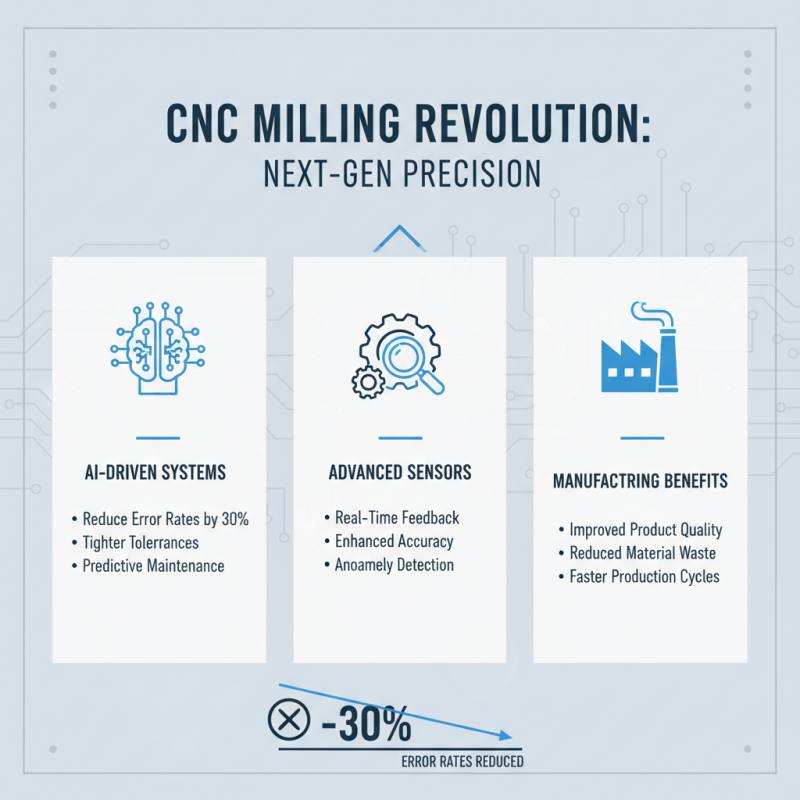

Innovative technologies are reshaping CNC milling, enhancing precision like never before. Recent reports indicate that integrating AI-driven systems can reduce error rates by up to 30%. These advancements help manufacturers achieve tighter tolerances in their products. The use of advanced sensors in CNC mills allows for real-time feedback, further improving accuracy.

For engineers, understanding the importance of toolpath optimization is crucial. Incorrect toolpaths can lead to greater wear, affecting both precision and lifespan. Using simulation software to visualize these paths before machining can save time and resources. Consider using advanced materials for cutting tools. They can offer greater resilience and maintain their sharpness longer.

Tips: Regularly maintain your equipment. Poorly maintained CNC mills can lead to inaccuracies. Also, invest in employee training. Skilled operators are less likely to make costly mistakes. Reflect on how tech might be over-relying. Not all situations necessitate high-tech solutions. Balancing technology with practical experience remains vital for engineers.

Comparative Analysis of Leading CNC Mill Brands and Models

When choosing a CNC mill for precision engineering, it's essential to analyze various brands and models. Each brand offers different features, catering to specific manufacturing needs. Some models excel in speed, while others prioritize accuracy. It's critical to weigh these factors before making a decision.

Quality and performance can vary greatly between machines. Some machines provide impressive cutting speeds but may struggle with intricate designs. Others maintain precision yet lack the versatility needed for diverse projects. Understanding these trade-offs can prevent costly mistakes in procurement.

User reviews often highlight these issues. Some users express frustration over the learning curve of complex machines. Maintenance challenges also arise, leaving users reflecting on their choices. An effective CNC mill should balance user-friendliness with technical capabilities, ensuring a smooth operation. These insights are vital in selecting the best CNC mill for your precision engineering needs.

2026 Best CNC Mill Machine for Precision Engineering

| Model | Max Cutting Speed (rpm) | Precision (µm) | Worktable Size (mm) | Weight (kg) | Price ($) |

|---|---|---|---|---|---|

| Model A | 12000 | 5 | 600 x 400 | 1200 | 5000 |

| Model B | 15000 | 3 | 800 x 500 | 1500 | 7500 |

| Model C | 10000 | 10 | 700 x 400 | 1300 | 5500 |

| Model D | 11000 | 4 | 900 x 600 | 1400 | 6000 |

Related Posts

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections

-

What is a CNC Machining Center and How Does it Benefit Manufacturing Industries

-

What is Manufacturing Machines and How They Transform Production Processes

-

How to Leverage Advanced Manufacturing for Next-Generation Production Efficiency

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes