How to Choose the Best CNC Cutting Machine for Your Business Needs

In the rapidly evolving manufacturing landscape, selecting the appropriate CNC cutting machine is crucial for optimizing operational efficiency and maintaining a competitive edge. According to a market analysis report by IndustryARC, the global CNC cutting machine market is anticipated to reach USD 5.6 billion by 2025, driven by increasing automation and the rising demand for precision in various industries, including metal fabrication, woodworking, and aerospace. As businesses strive to enhance production capabilities, understanding the diverse functionalities and specifications of CNC cutting machines becomes essential.

The choice of a CNC cutting machine not only impacts the quality of the final product but also the overall productivity of the manufacturing process. With advancements in technology, modern CNC cutting machines offer enhanced features, such as improved speed, accuracy, and versatility, which can significantly reduce operational costs. A survey from MarketsandMarkets indicates that the adoption of CNC cutting technology can result in up to a 30% decrease in material waste and a 25% increase in production speed. Therefore, businesses must carefully evaluate their specific needs, production volume, and material types when selecting the right CNC cutting machine to ensure alignment with their strategic goals and sustainability initiatives.

Understanding Your Business Requirements for CNC Cutting Machines

When selecting the best CNC cutting machine for your business, it's crucial to start with a clear understanding of your specific requirements. This means assessing the materials you plan to cut, the volume of production, and the precision needed for your projects. According to a report by MarketsandMarkets, the CNC cutting machine market is projected to reach $6.97 billion by 2025, highlighting the growing demand across various industries such as automotive, aerospace, and manufacturing. Each sector may have distinct needs, underscoring the importance of matching the machine's capabilities with your operational requirements.

In addition to material types and production volumes, consider the technological features that can enhance your workflow. For instance, advanced CNC machines offer capabilities such as real-time monitoring and automation, which are becoming increasingly essential in maintaining efficiency. A study published in the Journal of Manufacturing Processes emphasizes that businesses with automated CNC systems see a reduction in operational costs by up to 30%. Therefore, thoroughly evaluating your business needs against the technological advancements available in CNC cutting machines can lead to better investment decisions, ultimately driving productivity and profitability.

Comparative Analysis of CNC Cutting Machines Based on Key Features

Types of CNC Cutting Machines and Their Applications

CNC cutting machines have revolutionized various industries by offering precision and efficiency in production processes. These machines can be classified into several types based on their cutting methods, including laser cutting, plasma cutting, waterjet cutting, and routing. Each type has its specific applications, making it essential for businesses to understand their unique capabilities. For instance, laser cutting machines, known for their ability to cut intricate designs with minimal heat distortion, are widely used in the automotive and aerospace sectors, where precision is critical. According to a report by Market Research Future, the global laser cutting machine market is expected to reach $7.8 billion by 2025, highlighting the increasing demand for advanced cutting technologies.

Plasma cutting machines are another prominent category, ideal for cutting thicker materials like steel and aluminum. With their high-speed capabilities, plasma cutters enable manufacturers to boost productivity while maintaining quality. The Global Industry Analysts project that the plasma cutting equipment market will grow significantly, driven by the rising adoption in industries such as construction and metal fabrication. Meanwhile, waterjet cutting machines, which utilize high-pressure water to slice through materials, are favored in industries where the heat-affected zone must be minimized, such as in the processing of food and metals. This versatility makes them a preferred choice for manufacturers seeking flexibility in their production processes.

With the right CNC cutting machine, businesses can not only enhance production efficiency but also improve product quality and reduce operational costs. Understanding the specific benefits and applications of each machine type allows companies to make informed decisions tailored to their operational needs, leading to better outcomes in competitive markets.

| Type of CNC Cutting Machine | Common Applications | Material Types | Ideal for Industries | Cost Range |

|---|---|---|---|---|

| Laser Cutting Machine | Sheet metal cutting, fabric cutting, engraving | Metal, wood, acrylic, textiles | Manufacturing, fashion, signage | $10,000 - $300,000 |

| Plasma Cutting Machine | Metal fabrication, automotive repair | Steel, aluminum, copper | Heavy industry, automotive | $5,000 - $150,000 |

| Waterjet Cutting Machine | Complex shapes, glass cutting | Metal, stone, glass, ceramics | Aerospace, engineering, construction | $30,000 - $600,000 |

| CNC Router | Woodworking, furniture making | Wood, plastics, composites | Furniture, cabinetry, prototypes | $10,000 - $200,000 |

| CNC Laser Engraver | Personalized gifts, awards, signs | Wood, glass, metal, leather | Retail, promotional products | $5,000 - $50,000 |

Key Features to Consider When Selecting a CNC Cutting Machine

When selecting a CNC cutting machine for your business, several key features should guide your decision. First and foremost, the machine's precision and accuracy are crucial. Look for specifications that detail the machine's tolerance levels, as this will directly impact the quality of your finished products. A machine that can achieve high precision will reduce waste and enhance the efficiency of your manufacturing processes. Additionally, consider the cutting speed, as a faster machine can significantly increase productivity without compromising quality.

Another important feature to evaluate is the machine’s compatibility with various materials. Different applications may require cutting metals, plastics, or wood, each with unique properties and cutting requirements. Ensure that the CNC cutting machine you choose can handle the specific materials relevant to your business, and check if it offers versatility for future projects. Lastly, assess the ease of use and programming capabilities. A user-friendly interface and advanced software can streamline your operations, allowing for quicker setup times and reducing the likelihood of operator error. Prioritizing these features will help you select a CNC cutting machine that meets your business needs effectively.

Evaluating Budget and Cost-Effectiveness for Your CNC Investment

When evaluating the budget and cost-effectiveness of a CNC cutting machine, the first step is to determine your business needs and production demands. It's essential to consider not only the initial purchase price but also the long-term operational costs associated with the machine. This includes factors such as maintenance, tooling, and energy consumption. Businesses should perform a cost-benefit analysis to understand the return on investment, factoring in potential increases in productivity and efficiency that a high-quality CNC machine can bring.

Additionally, leasing options should be evaluated as they can offer lower upfront costs while allowing businesses to access advanced technology without a significant financial burden. Financing plans can also provide flexibility and ease the pressure on cash flow, making it feasible to invest in a more capable machine that meets your requirements. Analyzing the total cost of ownership over the lifespan of the machine will help ensure that the investment aligns with your budget while maximizing operational efficiency and profitability.

Maintenance and Support Considerations for CNC Cutting Machines

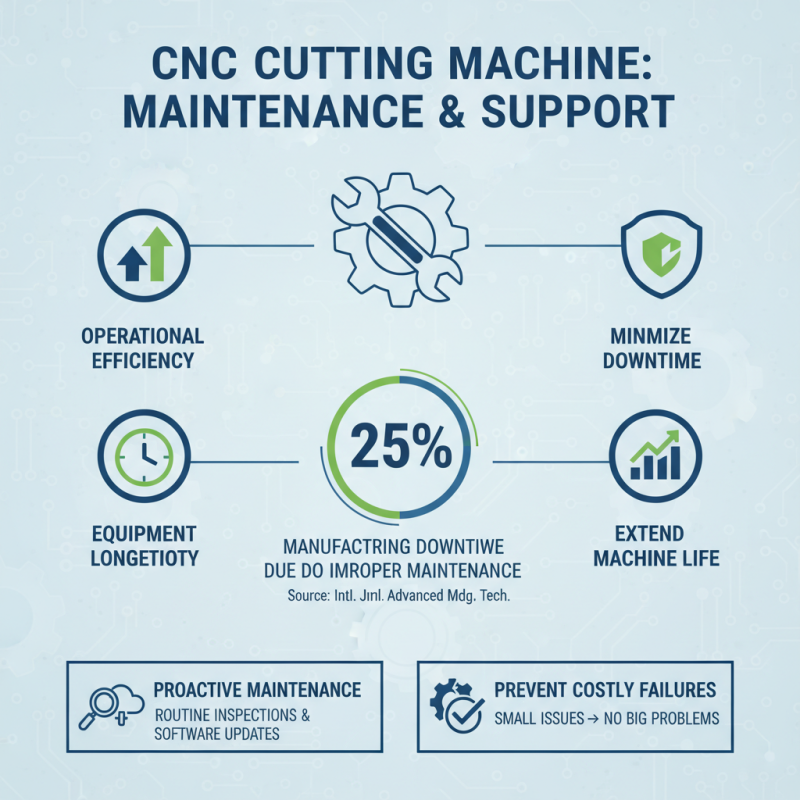

When selecting a CNC cutting machine for your business, maintenance and support considerations are pivotal for ensuring operational efficiency and longevity of the equipment. According to a report by the International Journal of Advanced Manufacturing Technology, more than 25% of manufacturing downtime is attributed to improper maintenance practices. Regular maintenance not only minimizes unexpected breakdowns but also significantly extends the life of the machinery. Businesses should implement a proactive maintenance routine, including routine inspections and software updates, to prevent small issues from escalating into costly failures.

Additionally, the quality of customer support provided by the CNC cutting machine manufacturer can greatly impact productivity. A study by Technavio highlighted that 45% of manufacturing firms prioritize after-sales service when purchasing CNC equipment. Rapid access to technical support can be a game-changer, helping businesses resolve operational issues promptly. Opting for vendors that offer comprehensive support packages, including training for staff and quick response times for technical assistance, ensures that companies can maintain optimal machine performance and minimize disruption to operations.

Related Posts

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

Why Precision CNC Machining is Essential for High Quality Manufacturing

-

What is CNC Work and How Does it Benefit Your Manufacturing Process