Why is CNC Automation Essential for Modern Manufacturing?

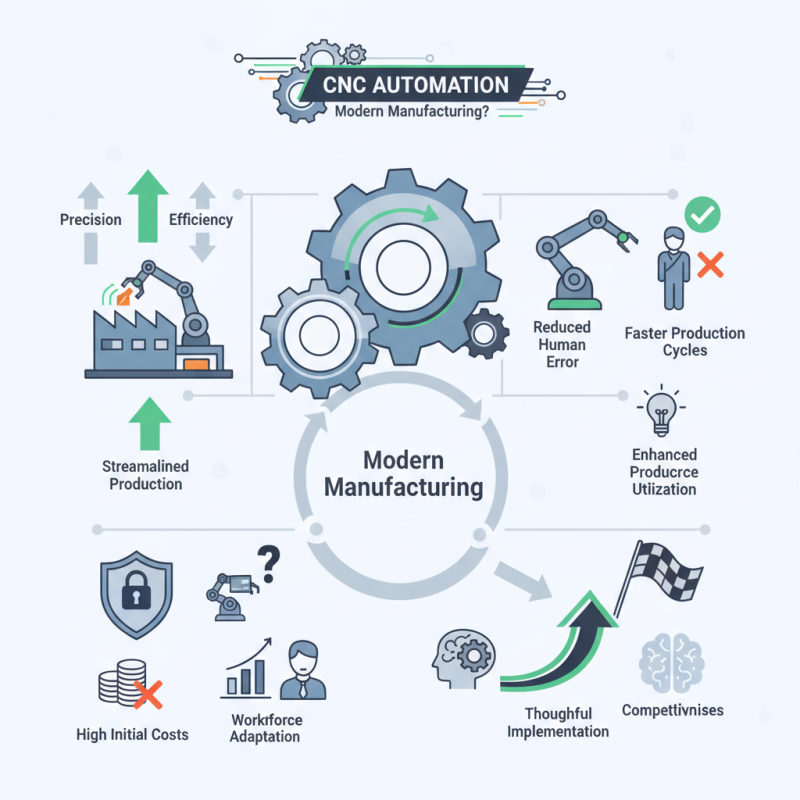

CNC automation is transforming modern manufacturing. Experts emphasize its significance in streamlining production processes. John Smith, a leader in CNC technology, once stated, “CNC automation is not just an upgrade; it’s a necessity for survival in today’s market.”

With the ever-increasing demand for precision and efficiency, manufacturers must adapt. CNC automation reduces human error and enhances productivity. It allows for faster production cycles and better resource utilization. However, many companies hesitate to adopt this technology. Change can be daunting, even when the benefits are clear.

Investing in CNC automation doesn't come without challenges. Initial costs might be high, and some workers may feel threatened by technological advancements. Companies need to balance innovation with workforce adaptation. Embracing CNC automation is essential for competitiveness, yet it requires thoughtful implementation.

The Role of CNC Automation in Enhancing Manufacturing Efficiency

CNC automation is transforming modern manufacturing. It enhances efficiency and precision in production processes. By using computer-controlled machines, companies reduce human error. This leads to higher quality products and faster turnaround times.

Tips: Invest in training. Ensure that employees understand CNC technology. This can improve productivity. Regular maintenance of machines is crucial. A well-maintained machine performs better and lasts longer.

Embracing CNC automation also has its challenges. Initial setup costs can be high. Not every factory can afford cutting-edge technology. It requires careful planning and budgeting. Balancing automation with skilled labor is crucial. Over-reliance on machines may lead to a skill gap in the workforce.

Tips: Start small. Implement CNC automation in specific areas. Measure the results before expanding. This cautious approach can mitigate risks. Seek feedback from operators to continuously improve the processes.

Key Advantages of CNC Automation Over Traditional Manufacturing Methods

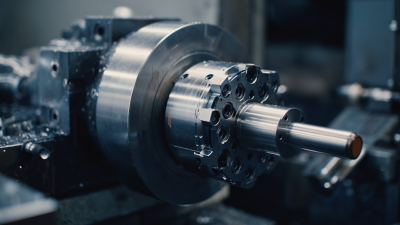

CNC automation offers significant advantages over traditional manufacturing methods. One major benefit is precision. CNC machines produce highly accurate parts consistently. This precision reduces waste and minimizes the need for rework. Imagine a factory where every component is exact; this leads to smoother assembly processes.

Speed is another key factor. CNC machines operate faster than manual methods. They can run continuously, producing parts around the clock. This efficiency enables manufacturers to meet growing demand. However, one must consider the initial investment in CNC technology, which can be high.

Flexibility is also vital. With CNC, switching between different tasks is easier. A programmer can modify the machine’s code in minutes. This adaptability can lead to increased innovation. Still, some traditional craftspeople worry about job security. Their skills might not be as valued. Balancing automation and craftsmanship is a critical conversation for the industry.

Advantages of CNC Automation Over Traditional Manufacturing Methods

This chart illustrates the key advantages of CNC automation compared to traditional manufacturing methods. Each advantage is rated on a scale from 1 to 10, highlighting CNC's superior precision, speed, cost efficiency, flexibility, and lower labor requirements.

Integration of CNC Automation in Modern Production Lines

The integration of CNC automation in modern production lines is no longer optional. In fact, companies that adopt CNC technology report up to a 30% increase in productivity. This leap in efficiency comes from precision and consistency, which manual processes struggle to achieve. A 2022 industry report by the International Federation of Robotics indicates that 75% of manufacturers now utilize CNC systems, underscoring their significance in current production environments.

However, challenges persist. Many workplaces face issues in the transition, causing downtime during system upgrades. Some workers resist change out of fear of job displacement. As automated processes become more prevalent, human oversight remains crucial. Data shows that 65% of CNC systems still require manual adjustments, illustrating that complete autonomy is not yet reality. These factors highlight the necessity for a balanced approach in integrating CNC automation.

Moreover, the initial investment in CNC machinery can be daunting. Companies often grapple with whether the returns justify the costs. Although a 2021 report found that 40% of businesses recoup their investment in less than two years, others experience delays. This variability indicates a need for comprehensive planning before implementation.

Impact of CNC Automation on Precision and Quality Control

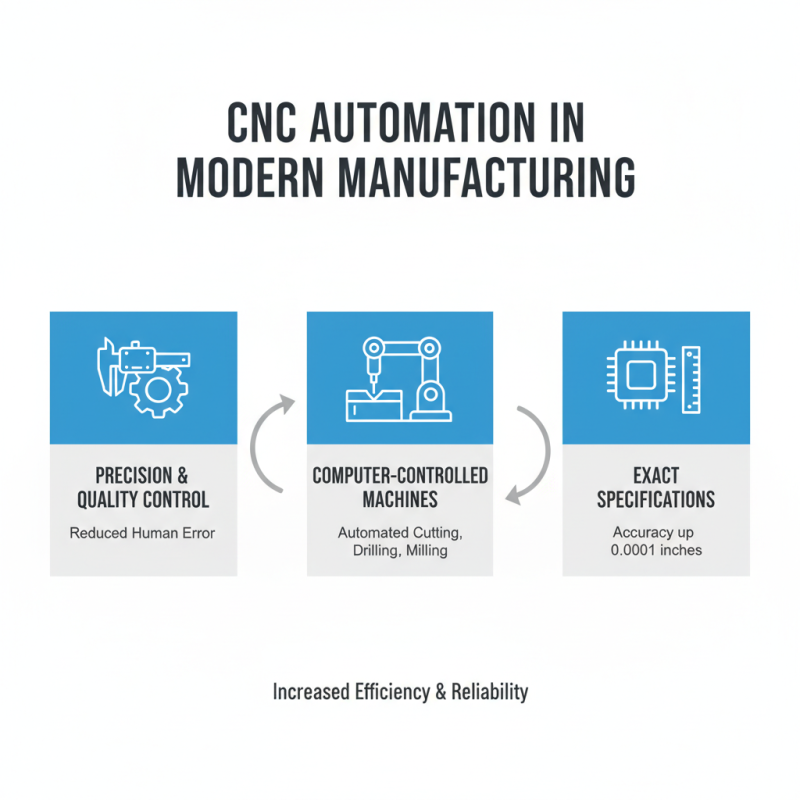

CNC automation plays a crucial role in modern manufacturing, particularly in precision and quality control. It uses computer-controlled machines to create parts that meet exact specifications. This method greatly reduces human error. For instance, a CNC machine can cut, drill, and mill with an accuracy of up to four decimal places. This level of precision was difficult to achieve with manual processes.

However, challenges arise. Not every component produced by CNC is flawless. Occasionally, the software or hardware may falter, leading to defects. These mistakes can compromise product quality. Manufacturers must be vigilant and diligent in monitoring output. Regular maintenance and calibrations are essential to ensure machines operate smoothly.

Moreover, the automation process can lead to a sense of detachment from the craft of manufacturing. Workers might lose skills that were once essential. Balancing technology and craftsmanship is important. Embracing CNC automation is necessary, but it shouldn’t overshadow the fundamental skills of manufacturing. Everyone benefits from both advanced technology and skilled labor.

Future Trends in CNC Automation for Sustainable Manufacturing Practices

CNC automation is transforming manufacturing. It enhances efficiency while promoting sustainability. According to a recent report by McKinsey, automation can reduce energy consumption in manufacturing by up to 30%. This reduction is crucial as global energy demand rises. Companies now prioritize technology that minimizes waste.

Future trends point towards integrating AI in CNC systems. AI could predict maintenance needs, reducing downtime. Siemens noted that predictive maintenance can save manufacturers approximately 12% of operational costs. Yet, challenges remain. Many manufacturers struggle to adopt these technologies due to high upfront costs. Not all have the resources for a seamless transition.

Sustainable practices are not merely about efficiency. They involve rethinking the entire manufacturing process. Implementing closed-loop systems in CNC machining is one such strategy. This approach can significantly reduce material waste. According to a study by the World Economic Forum, adopting circular economy principles can create a nearly $4.5 trillion opportunity by 2030. Many companies, however, hesitate to embrace these changes. They fear the initial investment will not pay off.

Related Posts

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

-

What is CNC Work and How Does it Benefit Your Manufacturing Process

-

What is a CNC Machining Center and How Does it Benefit Manufacturing Industries

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

How to Optimize Plastic CNC Machining for Better Precision and Efficiency

-

Top 10 Swiss Lathe Applications in Modern Manufacturing Industry