Top CNC Controllers of 2025: Features, Comparisons, and Buyer’s Guide

As the demand for precision manufacturing continues to soar, the role of CNC controllers in streamlining production processes has never been more critical. According to a recent analysis from industry specialists, the global CNC controller market is projected to reach $5.7 billion by 2025, reflecting a robust compound annual growth rate (CAGR) of 6.8%. This surge underscores the increasing adoption of advanced CNC technology across various sectors, including aerospace, automotive, and electronics.

In this evolving landscape, the choice of a CNC controller significantly impacts operational efficiency and output quality. With features ranging from enhanced user interfaces to advanced motion control capabilities, the right CNC controller can optimize machining processes, reduce errors, and increase productivity. As manufacturers seek to stay competitive in an increasingly automated environment, understanding the features and comparative advantages of different CNC controllers becomes essential. This guide will delve into the top CNC controllers of 2025, providing insight into their functionalities, key comparisons, and considerations for prospective buyers, ensuring that businesses can make informed decisions tailored to their specific needs.

Overview of CNC Controllers and Their Importance in Manufacturing

CNC controllers play a pivotal role in the manufacturing sector by facilitating precise automation of tools and machinery. These controllers serve as the brains of CNC machines, translating design specifications into motion and ensuring that operations are executed with high accuracy. According to a report by MarketsandMarkets, the global CNC market is projected to reach $117.21 billion by 2025, reflecting a growth rate driven by the increasing demand for automation in industries such as aerospace, automotive, and electronics. As companies strive for efficiency and consistency in production, the importance of advanced CNC controllers becomes evident.

When selecting a CNC controller, it's crucial to consider features such as software compatibility, ease of programming, and integration with existing systems. Modern controllers often come equipped with user-friendly interfaces and support for various programming languages, allowing for flexible production processes. Moreover, the integration of IoT technologies enhances the capabilities of CNC systems, providing real-time data analytics and monitoring that contribute to better operational decision-making.

Tips: When evaluating CNC controllers, assess the specific needs of your manufacturing processes. Look for options that offer scalability, as future growth may require additional features or capabilities. Additionally, consider implementations that provide robust technical support and training to maximize your investment in technology.

Key Features to Look for in CNC Controllers for Optimal Performance

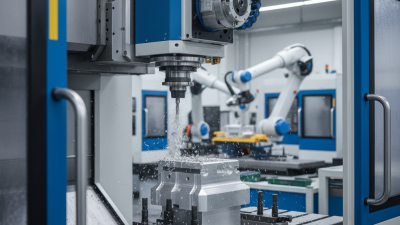

When selecting a CNC controller for optimal performance, several key features should be prioritized. First and foremost, the user interface plays a critical role in ensuring ease of operation. A well-designed interface with intuitive navigation allows operators to set up jobs quickly and efficiently, reducing the learning curve for new users. Moreover, customizable shortcuts can enhance productivity, allowing users to tailor the controller to their specific workflow needs.

Another crucial aspect is the compatibility of the CNC controller with various software applications. A versatile controller that supports multiple programming languages and file formats can streamline the workflow by allowing seamless integration with design software. Additionally, features like real-time monitoring and feedback mechanisms enable users to make informed decisions during the machining process, improving precision and reducing errors.

Finally, consider the controller's connectivity options, as robust communication capabilities can facilitate integration with other machinery and IoT devices, further enhancing operational efficiency.

Comparative Analysis of Leading CNC Controller Brands in 2025

In the evolving landscape of CNC technology, 2025 marks a year of significant advancements in the features and capabilities of CNC controllers. A comparative analysis reveals that leading brands are enhancing user experience through intuitive interfaces, streamlined setup processes, and robust software integrations. Many controllers now offer advanced options such as touchscreens and mobile compatibility, which cater to the modern demands of precision manufacturing. The adoption of cloud-based solutions for real-time data monitoring and remote control functionality is becoming a standard, further enhancing efficiency and productivity on the shop floor.

Moreover, performance metrics such as processing speed, accuracy, and compatibility with various machine types are pivotal points of comparison among leading controllers. Brands that prioritize customizable settings and programmable features are gaining favor among users who require flexibility for varying production tasks. Additionally, the integration of artificial intelligence and machine learning in CNC controllers is a growing trend, contributing to predictive maintenance and improved operational reliability. This moving trend toward smart CNC systems signifies a noteworthy shift in how manufacturers will approach their operations and investment decisions in the coming years.

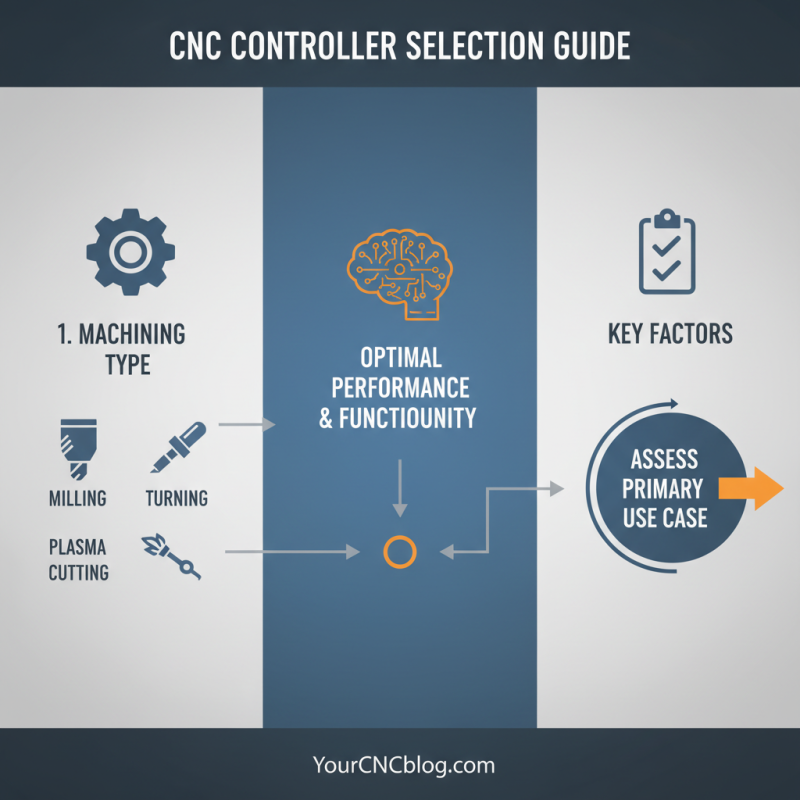

Buying Guide: Selecting the Right CNC Controller for Your Needs

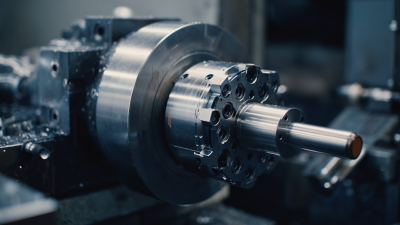

When selecting the right CNC controller for your needs, it is essential to consider several key factors to ensure optimal performance and functionality. First, assess the type of machining operations you plan to conduct. Different controllers are designed for specific applications, such as milling, turning, or plasma cutting. Understanding your primary use case will help you narrow down your options effectively.

Another critical aspect to consider is the user interface and software compatibility. A user-friendly interface can significantly boost productivity and reduce the learning curve, making it easier for both novice and experienced machinists to operate the equipment efficiently. Additionally, ensure that the software used is compatible with existing systems, allowing for smoother integration and better workflow.

**Tips:** Always look for a CNC controller that offers robust support and documentation. This can include tutorials, forums, and direct customer service, which can alleviate potential frustrations during installation and operation. Furthermore, consider future scalability; opt for controllers that allow for upgrades and expansion as your machining needs evolve.

Future Trends in CNC Technology and Their Impact on Controllers

As we look ahead to 2025, the CNC technology landscape is set to undergo significant transformations that will directly influence the development of controllers. One of the most notable trends is the integration of artificial intelligence and machine learning. Data from the International Federation of Robotics indicates that by 2025, AI-driven machines are expected to account for over 30% of global manufacturing automation, enhancing predictive maintenance capabilities and performance optimization. This trend will allow CNC controllers to not only execute tasks with greater precision but also learn from operational data to improve efficiency over time.

Another key factor shaping the future of CNC controllers is the shift towards greater connectivity and the Internet of Things (IoT). A recent report by Markets and Markets predicts that the IoT in manufacturing market will grow to $50 billion by 2025. This surge will enhance real-time communication between controllers and other machines, enabling a more interconnected manufacturing ecosystem. As a result, CNC controllers will need to accommodate advanced networking features, allowing seamless integration and collaboration across various platforms.

**Tip:** When considering a CNC controller for future operations, prioritize systems that offer AI features and robust IoT capabilities to stay ahead of industry changes.

Additionally, sustainability is becoming an essential aspect of CNC technology. Reports indicate that organizations that adopt eco-friendly practices see up to 30% reductions in operational costs. This push for greener manufacturing will drive the development of CNC controllers that not only optimize performance but also reduce energy consumption and waste, ensuring that businesses remain viable in an increasingly eco-conscious market.

**Tip:** Evaluate controllers based on their energy efficiency ratings and green certifications to align with sustainability goals while enhancing productivity.

Related Posts

-

Understanding CNC Controllers: Revolutionizing Precision Manufacturing with 30% Higher Efficiency

-

How to Optimize Plastic CNC Machining for Better Precision and Efficiency

-

What is Manufacturing Machines? A Comprehensive Guide to Industrial Equipment

-

10 Best CNC Machines for Precision Engineering in 2023

-

Why CNC Machine Tools Are Essential for Modern Manufacturing Success

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques