Why CNC Machine Tools Are Essential for Modern Manufacturing Success

In today's highly competitive manufacturing landscape, the importance of precision and efficiency cannot be overstated. CNC machine tools have emerged as crucial components in achieving these goals, revolutionizing the way products are designed and manufactured. As industry expert John Smith, a renowned engineer and consultant in advanced manufacturing technologies, aptly stated, “CNC machine tools are not just machines; they are the backbone of modern manufacturing, enabling unprecedented accuracy and productivity.” This statement highlights the transformative power of CNC technology, which has become indispensable for manufacturers striving to enhance their output while minimizing errors.

The integration of CNC machine tools into production processes allows for automated machining, leading to increased speed and consistency. By replacing traditional manual methods, these sophisticated machines enable companies to produce intricate designs with exacting precision, thereby meeting the growing demand for high-quality products. As we delve into the pivotal role that CNC machine tools play in modern manufacturing, it becomes evident that their adoption is essential not only for maintaining competitive advantage but also for fostering innovation within the industry.

The Definition and Functionality of CNC Machine Tools in Manufacturing

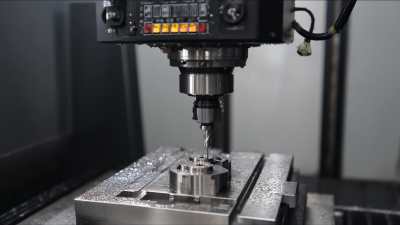

CNC (Computer Numerical Control) machine tools are pivotal in modern manufacturing due to their ability to automate complex tasks with precision and efficiency. Unlike traditional machining methods, CNC machines employ computerized controls to dictate the movement of tools, allowing for consistent production of intricate parts. This technology enables manufacturers to create components with tight tolerances and elaborate designs, significantly reducing human error and enhancing product quality.

The functionality of CNC machine tools extends beyond simple cutting and shaping of materials. These machines can perform various operations, including milling, turning, and drilling, all while being programmed to execute repetitive tasks with minimal manual intervention. This versatility makes CNC machining an invaluable asset for various industries, including aerospace, automotive, and medical. By streamlining processes and increasing production speed, CNC machine tools serve as a cornerstone for successful manufacturing operations, driving innovation and competitiveness in the market.

The Evolution of CNC Technology and Its Impact on Production Efficiency

The evolution of CNC (Computer Numerical Control) technology has revolutionized the manufacturing landscape, significantly enhancing production efficiency. Initially introduced in the 1940s and 1950s, CNC machines were rudimentary and limited. However, advancements throughout the decades, especially the integration of digital technology, have dramatically transformed their capability, precision, and usability. According to a report by the International Federation of Robotics, the global adoption of CNC machines has resulted in an efficiency increase of over 60% in various manufacturing sectors. The ability to automate complex processes allows manufacturers to produce intricate parts with minimal human intervention, thus improving throughput and reducing errors.

Moreover, CNC technology has enabled lean manufacturing practices, allowing for just-in-time production that minimizes waste and optimizes resource utilization. A study from the Manufacturing Institute indicates that companies utilizing CNC machining can see a reduction in operational costs by up to 30% due to decreased material waste and shorter lead times. This shift not only boosts productivity but also enhances the overall quality of the products being manufactured, ensuring that the end results meet stringent industry standards.

Tips: To maximize the benefits of CNC technology, consider investing in training for your operators. Skilled workers can better leverage the capabilities of CNC machines, leading to more efficient setups and maintenance. Additionally, regularly updating software and hardware can keep your machinery at the forefront of technology, ensuring optimal performance and adaptability to new manufacturing demands.

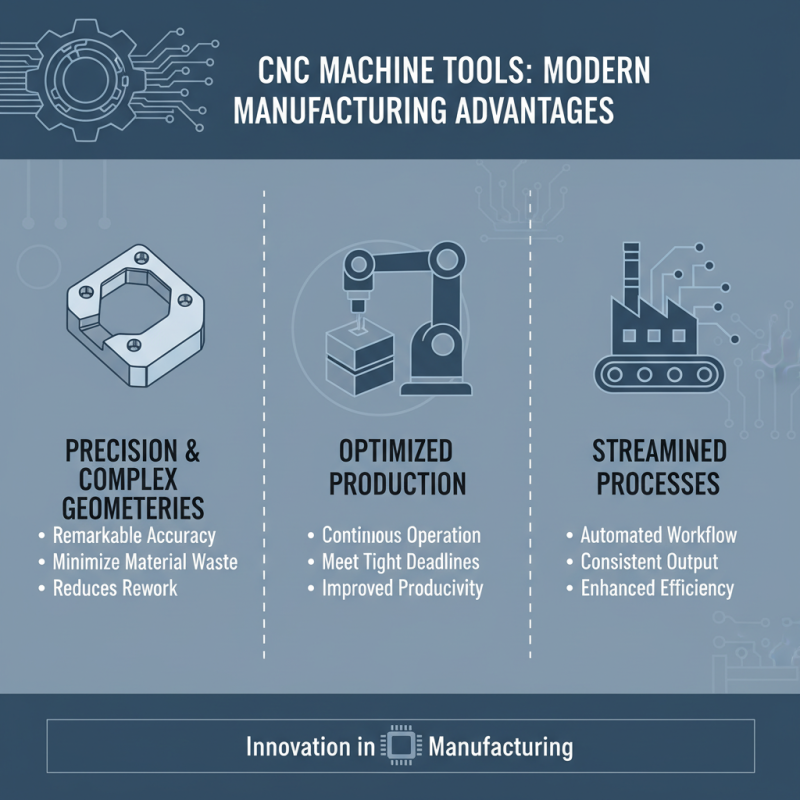

Key Advantages of Using CNC Machine Tools in Modern Manufacturing

CNC (Computer Numerical Control) machine tools have become an integral part of modern manufacturing, offering numerous advantages that streamline production processes and enhance precision. One of the key benefits of using CNC machine tools is their ability to produce complex geometries with remarkable accuracy. This precision minimizes material waste and reduces the need for extensive rework, thus improving overall productivity. Additionally, CNC machines can operate continuously, allowing manufacturers to optimize their production schedules and meet tight deadlines more effectively.

Another significant advantage of CNC machine tools is their versatility. These machines can be programmed to perform various tasks, including milling, turning, drilling, and even 3D printing, making them suitable for a wide range of applications across different industries. This adaptability not only enhances the manufacturing capabilities but also allows for flexibility in production, enabling manufacturers to quickly respond to changing market demands. Furthermore, the automation provided by CNC technology reduces human error, leading to higher quality outputs and increased consistency in product results.

Common Applications of CNC Machine Tools Across Different Industries

CNC machine tools have become a cornerstone of modern manufacturing, offering unparalleled precision and efficiency. Their common applications stretch across diverse industries, from aerospace and automotive to healthcare and electronics. In the aerospace sector, CNC machines are utilized for complex part fabrication, ensuring that components comply with the strict safety and performance standards necessary for flight.

Similarly, in automotive manufacturing, these tools are employed for producing high-quality parts with tight tolerances, significantly reducing the risk of defects and enhancing performance.

Similarly, in automotive manufacturing, these tools are employed for producing high-quality parts with tight tolerances, significantly reducing the risk of defects and enhancing performance.

Tips: When considering the adoption of CNC machine tools, assess the specific needs of your production line. Invest in training for your operators to maximize the capabilities of these tools, enhancing both safety and productivity. Furthermore, keeping your CNC machines well-maintained will ensure optimal performance and longevity, minimizing production downtime.

In the healthcare industry, CNC technology plays a crucial role in the creation of surgical instruments and prosthetics, where precision and customization are paramount. The electronics industry also benefits significantly, using CNC machining for the production of intricate circuit boards and housings. As various sectors continue to embrace automation and technology, CNC machine tools will remain an essential element for achieving manufacturing excellence.

Tips: Stay updated on the latest advancements in CNC technology to keep your manufacturing processes competitive. Embrace software solutions that streamline design and production workflows, enabling more efficient use of CNC capabilities.

Future Trends in CNC Machining Technology and Manufacturing Integration

The future of CNC machining technology is poised for significant evolution, influenced by advancements in automation, artificial intelligence, and data analytics. According to a recent report by Grand View Research, the global CNC machine market is expected to reach $100 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.6%. This growth reflects the increasing demand for precision and efficiency in manufacturing processes. As manufacturers integrate smart manufacturing principles, CNC machines will increasingly communicate in real-time with other machines and IoT devices, leading to improved operational efficiency and reduced production costs.

Moreover, Industry 4.0 and smart factory initiatives are driving the adoption of integrating CNC machining with advanced manufacturing technologies. A survey by Deloitte highlighted that 79% of manufacturers believe that the integration of AI and machine learning into CNC machining will be critical for maintaining competitive advantage. This integration will not only enhance the precision and speed of machining processes but also facilitate predictive maintenance, reducing downtime and maximizing productivity. As these trends continue to unfold, the ability of CNC machine tools to adapt and integrate with other technologies will be a key determinant of success in modern manufacturing environments.

Related Posts

-

Top 10 CNC Machining Centers: Which One is Best for Your Needs?

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections