What is a CNC Machining Center and How Does it Benefit Manufacturing Industries

The modern manufacturing landscape is witnessing a significant transformation driven by technological advancements, particularly with the rise of the CNC machining center. A CNC (Computer Numerical Control) machining center is an advanced machine tool that automates the machining process with unparalleled precision and efficiency. According to recent industry reports from the Machinery Research Institute, the CNC machining center market is projected to grow at a CAGR of 6.5% over the next five years, highlighting its increasing adoption in various sectors including aerospace, automotive, and medical industries.

The benefits of utilizing a CNC machining center extend beyond mere automation; these systems offer improved accuracy, reduced waste, and enhanced production rates. Research indicates that manufacturers leveraging CNC technology can achieve up to a 50% reduction in production time, while also minimizing human error. Furthermore, with the demand for customized and complex components rising, CNC machining centers provide the flexibility to easily modify designs, making them an invaluable asset in meeting market demands efficiently. As industries continue to embrace digital transformation, understanding the capabilities and advantages of CNC machining centers will be crucial for maintaining a competitive edge in the manufacturing sector.

What is a CNC Machining Center?

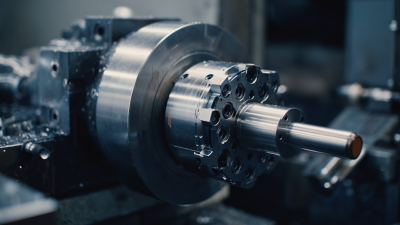

A CNC machining center is a versatile and sophisticated piece of equipment used in the manufacturing industry for precision machining tasks. It combines multiple functions, such as milling, drilling, and tapping, into a single machine, allowing for high efficiency and accuracy in production. The center operates through Computer Numerical Control (CNC) technology, where a computer program controls the movements and operations of the machine based on precise specifications. This automation enhances repeatability, reduces human error, and increases overall productivity.

Tips: When selecting a CNC machining center, consider factors such as the machine's compatibility with the materials you plan to work with, the complexity of the parts you need to produce, and the required tolerances. Additionally, ensure that your workforce is adequately trained in operating and programming CNC machines to maximize the benefits of this technology.

CNC machining centers also contribute significantly to reducing lead times in manufacturing processes. By integrating multiple machining processes, they minimize the need for tool changes and human intervention. This streamlining of workflows not only accelerates production times but also enables manufacturers to respond swiftly to market demands or custom orders, making them a vital asset in today’s competitive manufacturing landscape.

CNC Machining Center Usage in Different Manufacturing Sectors

Key Components of CNC Machining Centers

CNC machining centers play a vital role in modern manufacturing, enhancing production efficiency and precision. These sophisticated machines are equipped with key components that significantly contribute to their functionality. The core of a CNC machining center includes a spindle, tool holder, and a series of axes that enable multidirectional movement. Spindles use high-speed rotation to facilitate operations such as drilling, milling, and turning, which are essential for shaping parts from various materials.

Another critical element is the CNC controller, which interprets the software commands and translates them into mechanical movements. This technology allows for complex geometries and intricate designs to be produced with minimal operator intervention. According to a report by MarketsandMarkets, the CNC machining market is projected to reach $117.84 billion by 2025, driven by the increasing demand for precision engineering across various sectors, including aerospace and automotive industries. Furthermore, the ability of CNC machining centers to operate continuously, achieving high productivity rates, makes them indispensable in competitive manufacturing environments. The integration of automation and advanced sensors into CNC centers also contributes to reduced cycle times and enhanced product quality, further solidifying their importance in contemporary manufacturing processes.

How CNC Machining Centers Operate

CNC machining centers are pivotal in modern manufacturing, employing computer numerical control technology to automate the machining process. These centers operate through precise programming that directs the machinery in executing complex tasks such as milling, turning, and drilling. According to a report by Research and Markets, the CNC machining market is expected to reach $100 billion by 2026, highlighting the growing significance of these centers in enhancing productivity. The operational efficiency of CNC machining centers lies in their ability to reduce human error and maintain high levels of precision, which is critical in industries like aerospace and automotive where tolerances are extremely tight.

The operation of CNC machining centers involves the use of CAD (Computer-Aided Design) software to create detailed designs that the CNC machine will follow. Once programmed, the machine interprets the instructions into physical movements, allowing for the consistent production of elaborate components with minimal manual intervention. A study by Statista indicates that approximately 70% of manufacturers have adopted CNC technology, showcasing its increasing integration into industry standards for quality and efficiency. This automation results not only in faster production times but also in significant cost savings, as fewer resources are required for material waste and labor-intensive processes.

Advantages of CNC Machining Centers in Manufacturing

CNC machining centers have become integral to manufacturing across various industries due to their unparalleled precision and efficiency. One of the primary advantages of utilizing CNC machining centers is the ability to automate complex tasks with minimal human intervention. According to a report from The Freedonia Group, the demand for CNC machinery is anticipated to reach $6.8 billion by 2026, highlighting its growing significance. This form of automation not only reduces labor costs but also enhances productivity, allowing manufacturers to meet increasing market demands swiftly.

Moreover, CNC machining centers significantly improve product quality and consistency. By utilizing computer-aided designs and advanced algorithms, manufacturers can achieve tight tolerances and replicate designs accurately. The American National Standards Institute (ANSI) reports that precision machining can reduce material waste by up to 30%, lowering production costs and benefiting the environment. This efficiency is particularly crucial in industries such as aerospace and automotive, where part integrity and precision are paramount.

Tips: To maximize the benefits of CNC machining, manufacturers should invest in training for their workforce to ensure they understand the technology fully. Regular maintenance of machines is also essential to prevent any downtime, which can affect production schedules. Embracing the latest software updates can help in maintaining competitiveness within the industry.

Applications of CNC Machining Centers Across Industries

CNC machining centers are versatile tools used across various manufacturing industries, offering precision and efficiency in production processes. These centers find applications in fields such as aerospace, automotive, medical devices, and electronics. In aerospace, for example, the intricate shapes of components like turbine blades and structural parts can be effectively produced using CNC machining, ensuring both reliability and adherence to stringent safety standards. The automotive industry similarly benefits as CNC machining centers enable the rapid production of complex parts required for modern vehicles, optimizing both performance and cost-effectiveness.

In the medical field, CNC machining centers are pivotal in creating high-precision components for surgical instruments and implants, ensuring they meet the necessary biocompatibility and performance criteria. Additionally, in the electronics industry, these machines facilitate the manufacturing of complex circuit boards and housings with high accuracy and repeatability.

Tips: When integrating CNC machining into production, it's essential to invest in proper training for operators. Understanding the full potential of the equipment can greatly enhance productivity and reduce errors. Regular maintenance of the CNC machines also ensures longevity and consistent output quality, so scheduling routine check-ups is advisable.

Related Posts

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

10 Best CNC Machines for Precision Engineering in 2023

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

Top 10 Benefits of Using CNC Turning Machines for Precision Manufacturing