CNC Machining Center Tips for Beginners How to Get Started

CNC machining centers are revolutionizing the manufacturing industry. According to a recent report by Technavio, the global CNC machining center market is projected to grow by over $2 billion from 2021 to 2025. This growth highlights the increasing demand for precision engineering and automated solutions. However, for beginners, navigating this technology can be daunting.

John Smith, a leading expert in CNC machining, states, "Understanding the basics is crucial for success in this field." Many newcomers struggle with complex programming and setup processes. Mistakes in these early stages can significantly impact production quality. It’s essential to acknowledge these challenges and learn from them.

Investing time in proper training can pay off in the long run. Beginners should focus on mastering fundamental skills before diving deeper into advanced techniques. CNC machining centers offer vast capabilities, yet those capabilities can go unused without a solid foundation. Embracing the learning curve can lead to rewarding outcomes.

Understanding CNC Machining Centers and Their Components

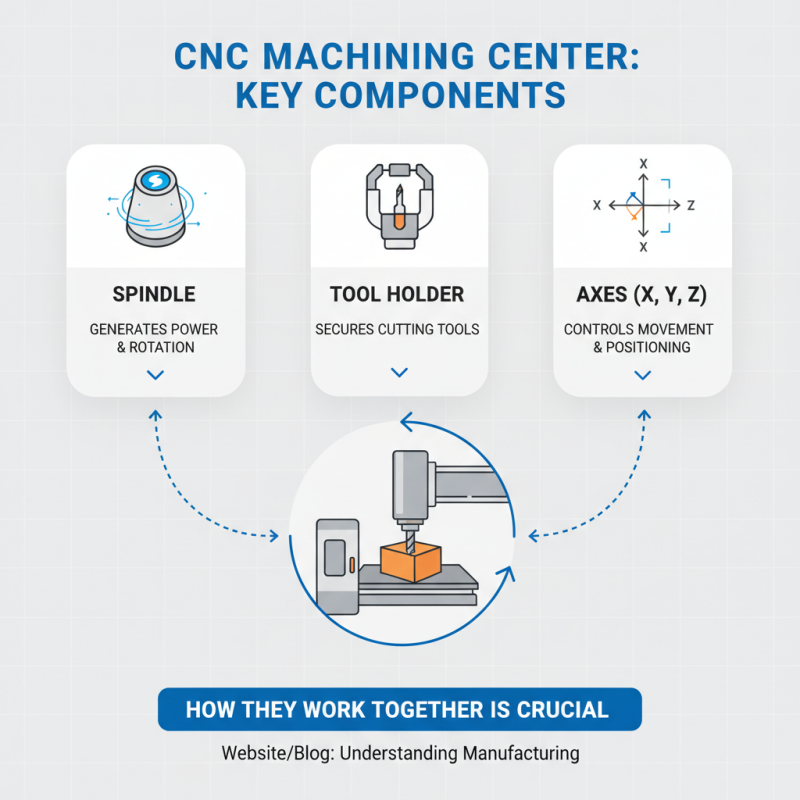

CNC machining centers are complex machines vital for modern manufacturing. Understanding these machines starts with their key components. The main parts include the spindle, tool holder, and axes. The spindle generates power, while the tool holder secures the cutting tools. Knowing how these work together is crucial for beginners.

The axes control the movement of the machine. Typically, CNC machines operate on three or five axes. More axes allow for intricate designs and precision cuts. However, this complexity can be overwhelming. New users might struggle with the controls or software. Mistakes can happen, leading to scratched or unusable parts. It's essential to practice and learn from these errors.

Additionally, operators should not overlook the importance of maintenance. Regular checks on the machine’s components are vital. A neglected spindle can lead to poor performance. Always strive for improvement. Don't allow initial setbacks to discourage you. Learning CNC machining is a gradual process. Each mistake offers a lesson, contributing to your growth.

Essential Tools and Equipment Needed for CNC Machining

When starting with CNC machining, having the right tools is critical. A sturdy CNC machine forms the core of your setup. Choose one that fits your project needs. A desktop model might work well for small tasks, while larger projects may need industrial-grade machines. Remember, bigger isn’t always better; assess your workspace before deciding.

In addition to the machine, essential tools include a precision measuring instrument. Calipers and micrometers help ensure accuracy. Don’t overlook tooling options. End mills and drill bits are necessary for various projects. Selecting the right material for tooling can significantly impact your output.

Software is another crucial component. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software will guide your designs. However, they can be complex. Expect a learning curve. Patience is necessary as you navigate these programs. Mistakes will happen. They often lead to necessary adjustments in your approach. Embrace this process; it is part of becoming adept in CNC machining.

CNC Machining Center Tips for Beginners: Essential Tools and Equipment Needed for CNC Machining

| Tool/Equipment | Purpose | Recommended Size/Type | Estimated Cost |

|---|---|---|---|

| CNC Milling Machine | Used for precise cutting and shaping of materials. | 3-Axis or 5-Axis | $10,000 - $50,000 |

| CNC Router | Ideal for cutting wood, plastics, and soft metals. | Router table size 48"x96" | $2,000 - $20,000 |

| CAD Software | Used for designing parts and generating CNC programming code. | AutoCAD or Fusion 360 | $300 - $1,500 per license |

| Tool Holders | Securely hold cutting tools in the CNC machine. | ER Collet Chuck | $50 - $200 each |

| Cutting Tools | Used for the actual cutting of the material. | End Mills, Drill Bits | $10 - $100 each |

| Workholding Devices | Keep the workpiece secure during machining. | Vises, Clamps | $100 - $1,000 |

Basic CNC Programming Concepts for Beginners

When diving into CNC programming, understanding its basics is crucial. CNC stands for Computer Numerical Control. It allows us to control machines using software. This opens up various possibilities for precision machining. Familiarize yourself with G-code, the language used by CNC machines. It's essential for programming specific movements. For example, G00 commands the machine to move quickly to a specified point.

Here are a few tips to ease your journey. Start with simple projects. Create basic shapes instead of complex designs. This will help you grasp G-code fundamentals faster. Don’t be afraid of making mistakes. Each error teaches a valuable lesson. Troubleshooting is part of the learning process.

Also, invest time in understanding the machine's interface. Spend time practicing before running the actual program. Running a program without practice can lead to waste and frustration. Pay attention to tool paths. They will affect material precision and the final product outcome. With patience and practice, you'll grow more confident in CNC programming.

Safety Precautions and Best Practices in CNC Machining

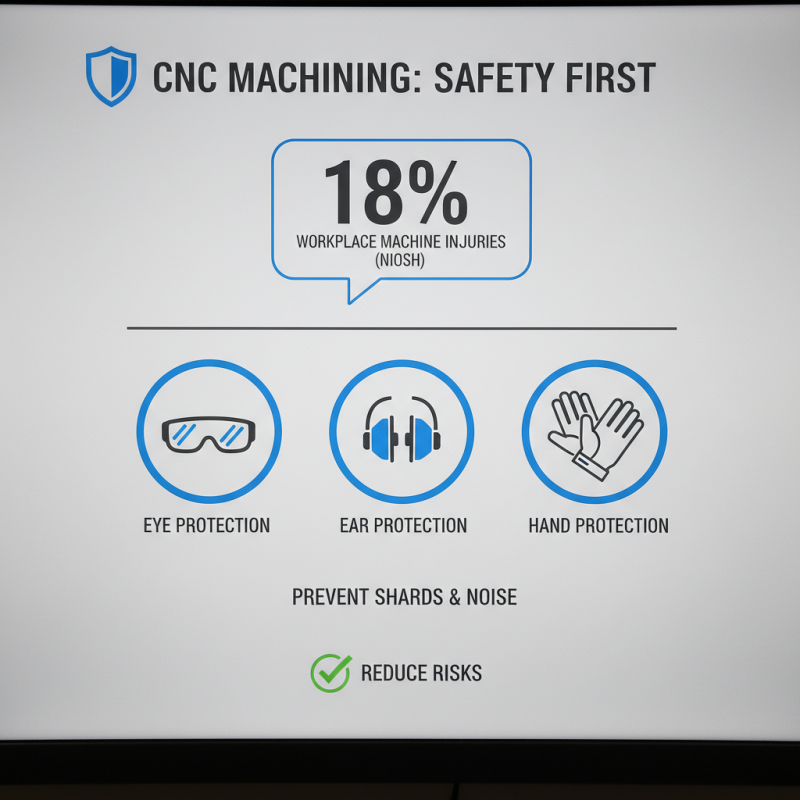

When starting with CNC machining, safety is a top priority. According to the National Institute for Occupational Safety and Health (NIOSH), machine-related injuries account for about 18% of workplace accidents. Proper precautions can significantly reduce these risks. Always wear protective gear, including eye protection, earplugs, and gloves. These items are essential for safeguarding against metal shards and noise.

It's also crucial to understand machine components and their operation. Beginners should familiarize themselves with emergency stop buttons and safety interlocks. Training is often overlooked. A study by the Manufacturing Institute indicates that companies investing in training see a 26% decrease in injuries. Always keep the work area clean and organized. Clutter can lead to accidents and hinder efficient workflow.

Mistakes will happen, especially for newcomers. Learning from them is key. Regular machine maintenance isn’t just a recommendation; it’s a necessity. Unmaintained machines can malfunction, which may result in severe injuries. Reflect on your practices frequently. Identify what goes wrong and adjust. This iterative process improves safety and efficiency in CNC machining.

Tips for Setting Up Your First CNC Project Effectively

Starting your first CNC project can feel overwhelming. Many beginners underestimate the importance of planning. Set clear goals for what you want to create. Sketch a rough design to visualize your ideas. Having a clear image helps during the setup. Use simple tools to measure and outline your project. This will save time and reduce mistakes.

Choose the right materials for your project. Some materials are easier to work with than others. For instance, softwoods can be forgiving but may not hold up well. Metal projects require more precise settings. Don’t rush this step. Test various materials to see how your CNC machine responds. Remember, not every attempt will be perfect. Learning from mistakes is key to success.

Lastly, familiarize yourself with the software. The interface can be tricky at first. Take the time to explore and test functions. Many users make errors by not fully understanding the program. If something goes wrong, step back and analyze the situation. Reflecting on these moments will provide valuable lessons for your next project. Embrace the journey and keep experimenting.

Related Posts

-

2026 Best CNC Machine Working Techniques for Optimal Performance

-

10 Best CNC Machines for Precision Engineering in 2023

-

Why Precision CNC Machining is Essential for High Quality Manufacturing

-

10 Essential Tips for Choosing CNC Machine Tools for Your Projects?

-

What is a CNC Machining Center and How Does it Benefit Manufacturing Industries

-

Why CNC Machine Tools Are Essential for Modern Manufacturing Success