Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

The landscape of modern manufacturing is continuously evolving, and at the forefront of this transformation are CNC machining parts. These components play a vital role in enhancing efficiency, precision, and flexibility in various industries. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2025, reflecting an annual growth rate of over 6%. This significant increase underscores the rising demand for CNC machining parts, which are critical for producing high-quality finished products with minimal waste.

As manufacturers strive to improve operational efficiency and reduce production costs, CNC machining parts offer numerous advantages that are hard to overlook. A study from Technavio highlights that CNC machining contributes to a reduction in lead times by up to 75%, providing companies with the agility needed to respond swiftly to market changes. Furthermore, the precision offered by CNC machining parts ensures that manufacturers can meet stringent quality standards, a necessity in industries such as aerospace and automotive, where even the slightest deviation can lead to catastrophic consequences.

In conclusion, the indispensability of CNC machining parts in modern manufacturing cannot be overstated. As industries continue to embrace automation and advanced manufacturing technologies, investing in high-quality CNC machining parts will play a pivotal role in driving efficiency, productivity, and competitiveness. This article delves deeper into the industry insights and data that showcase the essential nature of CNC machining parts in the ever-evolving manufacturing sector.

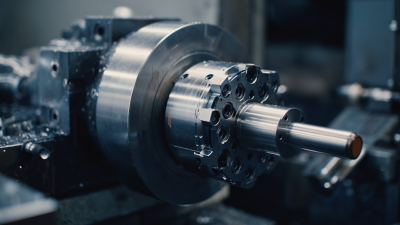

The Role of CNC Machining in Optimizing Manufacturing Processes

CNC machining plays a pivotal role in optimizing manufacturing processes by streamlining production and enhancing precision. The automation of machining processes allows manufacturers to achieve high levels of consistency and accuracy, which are crucial in meeting the demands of modern industries. As businesses strive for greater efficiency, integrating CNC machining into their workflows enables rapid prototyping and flexible manufacturing solutions, significantly reducing lead times.

Moreover, the adoption of CNC machining technologies has transformed traditional manufacturing approaches. By utilizing computer numerical control, manufacturers can easily adjust designs and specifications without extensive retooling, which is often time-consuming and costly. This adaptability not only aids in the production of complex geometries but also minimizes waste, making operations more sustainable. The overall impact is a more responsive manufacturing environment that can quickly pivot to meet market demands while maintaining high-quality standards.

Impact of CNC Machining on Manufacturing Efficiency

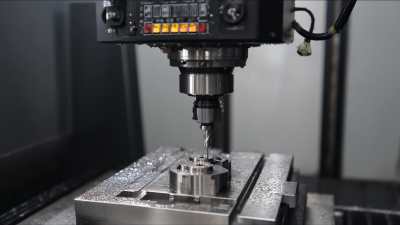

Key Advantages of CNC Machining Over Traditional Methods

CNC machining has revolutionized modern manufacturing, offering several key advantages over traditional machining methods. One of the most significant benefits is precision. According to a report by Grand View Research, CNC machines can achieve tolerances as tight as ±0.005 inches, enhancing part accuracy and performance. This level of precision not only reduces material waste but also minimizes the need for extensive rework, streamlining production processes and improving overall efficiency.

Another advantage is the ability to automate repetitive tasks, which drastically increases productivity. A study published by the National Institute of Standards and Technology highlights that CNC machining can improve production speeds by up to 75% compared to manual machining processes. This automation enables manufacturers to reduce labor costs and allocate human resources to more strategic tasks. Moreover, CNC technology facilitates complex geometries that were previously challenging or impossible to achieve manually, enabling innovation and customization in product design that meets diverse consumer demands.

Emerging Trends in CNC Technology for Enhanced Production Efficiency

Emerging trends in CNC technology are reshaping the manufacturing landscape, driving significant improvements in production efficiency across various industries. The integration of advanced digital manufacturing technologies facilitates precise machining, leading to reduced lead times and improved quality control. As industries increasingly adopt automation and data analytics, manufacturers can optimize their processes and reduce operational costs considerably.

Tips: Consider implementing a robust data analytics system to monitor machine performance and identify bottlenecks in your production line. This proactive approach can lead to significant efficiency gains.

Another noteworthy trend is the growing prevalence of hybrid additive manufacturing machines that combine traditional subtractive processes with additive techniques. This innovation allows for more complex geometries and multi-material capabilities, which were previously unachievable. As this technology evolves, it will become a crucial component in high-volume production environments.

Tips: Stay informed about the latest CNC technologies and attend industry seminars or workshops to enhance your knowledge and application skills. This continuous learning will ensure you stay competitive in an ever-evolving market.

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

| Dimension | Value | Trend |

|---|---|---|

| Production Speed | 20% Increase | Rising Automation in CNC |

| Material Waste | 10% Reduction | Advanced Cutting Techniques |

| Lead Time | 15% Decrease | Just-In-Time Production |

| Machine Efficiency | 95% Efficiency | Integration of IoT Technology |

| Cost Reduction | 25% Savings | Improved CNC Processes |

Data-Driven Insights into CNC Machining's Impact on Manufacturing Costs

CNC machining plays a pivotal role in enhancing manufacturing efficiency, significantly impacting production costs across various industries. Recent industry reports show that the CNC machine market is projected to reach substantial growth by 2032, driven by the adoption of innovative digital manufacturing technologies. These technologies streamline workflows and bolster productivity, resulting in reduced operational expenses. For instance, the integration of generative AI and advanced data analytics is revolutionizing manufacturing metrology, optimizing precision and adaptability in processes.

Furthermore, employing predictive maintenance through deep learning models enhances operational efficiency, by minimizing downtime and maintenance costs. Studies indicate that manufacturers implementing predictive maintenance strategies can see up to a 25% reduction in operational costs. As industries continue to embrace AI advancements, such as autonomous robotics and generative design, the operational landscape is becoming increasingly efficient, ensuring that manufacturers maintain a competitive edge in a rapidly evolving market. These data-driven insights underline the transformative impact of CNC machining and AI on modern manufacturing practices.

Future Projections: CNC Machining's Influence on Industry 4.0 Initiatives

As industries evolve towards Industry 4.0, CNC machining is becoming increasingly pivotal. According to a recent report by the International Data Corporation (IDC), the global CNC machining market is expected to reach $100 billion by 2026, with a compound annual growth rate (CAGR) of 7.5%. This growth is driven by advances in automation and connectivity, which are essential components of smart manufacturing. CNC machining processes are now integrated with advanced data analytics and IoT technologies, allowing for real-time monitoring and optimization of production systems.

Furthermore, a study by Statista highlights that over 70% of manufacturers using CNC machines have reported improvements in efficiency and productivity due to the adoption of Industry 4.0 technologies. The ability to quickly switch between production lines and customize parts on demand not only reduces lead times but also minimizes waste, aligning with the principles of lean manufacturing. As companies aim to enhance flexibility and responsiveness in their operations, CNC machining stands out as a crucial technology, enabling them to meet the increasing demands for personalized products while maintaining operational efficiency.

Related Posts

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections