Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing

In today's rapidly evolving manufacturing landscape, CNC programming has emerged as a fundamental skill for beginners looking to navigate the complexities of modern production techniques. As industries increasingly adopt advanced machinery, understanding the principles of CNC programming becomes essential for gaining a competitive edge. This introduction serves as a gateway to unraveling the secrets of this vital discipline, offering insights into its core concepts, practical applications, and the tools necessary for success.

CNC programming not only enhances the precision and efficiency of manufacturing processes but also empowers newcomers to innovate and contribute meaningfully to their teams. By mastering the foundational elements of CNC programming, beginners can unlock potential career pathways in fields ranging from aerospace to automotive, all while fostering a deeper appreciation for the technology shaping our world. As we delve deeper into the intricacies of CNC programming, we will explore effective strategies, tips, and resources aimed at turning novices into proficient operators, enabling them to thrive in an increasingly automated industry.

Understanding the Basics of CNC Programming and Its Importance in Modern Manufacturing

CNC programming is a fundamental aspect of modern manufacturing that significantly enhances productivity and precision. According to a report by the International Federation of Robotics, the global market for CNC machines is projected to reach $80 billion by 2025, highlighting the automation trend and the critical role of CNC technology in various industries. Understanding the basics of CNC programming not only empowers beginners to operate machines but also enables them to optimize processes and reduce production costs.

Tip: Start by familiarizing yourself with fundamental terms like G-code and M-code, as they form the backbone of CNC programming.

Moreover, learning CNC programming is increasingly essential as industries face pressures to improve efficiency and reduce waste. A study from the National Institute of Standards and Technology reveals that companies utilizing advanced manufacturing technologies, including CNC systems, can see productivity gains of up to 30%. By mastering these programming skills, beginners can set themselves apart in a competitive job market where proficiency in automated processes is increasingly sought after.

Tip: Consider utilizing online resources and simulation software to practice CNC programming without the need for physical machines.

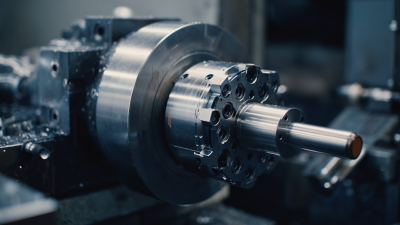

Key Components of CNC Machines and Their Functions for Beginners

CNC programming plays a pivotal role in modern manufacturing, especially for those who are just starting in the field. Understanding the key components of CNC machines is essential for beginners. Typically, a CNC machine consists of a controller, spindle, and tooling system. The controller serves as the brain, translating programming code into precise movements of the machine. The spindle is responsible for rotating the cutting tool, while the tooling system facilitates accurate material removal. Reports indicate that the global CNC machine market is projected to reach $100 billion by 2025, highlighting its significance in achieving efficient and scalable manufacturing processes.

Moreover, as technology advances, the integration of AI and automation within CNC machinery has transformed traditional programming practices. For instance, advancements in machine learning enable CNC machines to adapt to various manufacturing tasks by optimizing settings in real time. Recent studies reveal that implementing AI can increase productivity by up to 20%, ensuring greater operational efficiency. Therefore, beginners must familiarize themselves with these fundamental components and the evolving technological landscape to harness the full potential of CNC programming in modern manufacturing environments.

Essential Software Tools for CNC Programming: A Beginner's Guide

CNC programming has revolutionized modern manufacturing, making it essential for beginners to familiarize themselves with key software tools that drive efficiency and accuracy. According to a report by the International Federation of Robotics, the use of CNC machinery is expected to grow by 15% annually, highlighting the importance of mastering the foundational software that powers this technology. Tools such as Fusion 360, SolidWorks, and Mastercam stand at the forefront, offering intuitive interfaces and advanced capabilities tailored for newcomers in the manufacturing field.

Fusion 360, for instance, combines CAD, CAM, and CAE in a single platform, enabling seamless transitions from design to manufacturing. This integration not only streamlines workflows but also significantly reduces lead times, something critical in a competitive market. Additionally, a survey by the National Institute of Standards and Technology indicated that manufacturers who adopted CNC programming reported a 30% increase in production efficiency. By equipping themselves with the right software tools, beginners can harness the full potential of CNC programming, positioning themselves for success in the evolving landscape of manufacturing.

Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing - Essential Software Tools for CNC Programming: A Beginner's Guide

| Software Tool | Primary Function | User Level | Operating System |

|---|---|---|---|

| Fusion 360 | CAD/CAM Design | Beginner to Intermediate | Windows, Mac |

| SolidWorks | 3D CAD Modeling | Intermediate to Advanced | Windows |

| Mastercam | CNC Programming | Beginner to Advanced | Windows |

| HSMWorks | Integrated CAM | Intermediate | Windows |

| Gcode Ripper | G-code Generation | Beginner | Windows |

Step-by-Step Guide to Writing Your First CNC Program

CNC programming can seem daunting for beginners, but with a structured approach, anyone can write their first CNC program successfully. A step-by-step guide is essential. Start by familiarizing yourself with the basics of CNC machines and how they operate. Understanding the fundamental components—such as the controller, motors, and the type of tooling required—is crucial. According to a recent industry report, around 75% of manufacturing companies indicate a growing need for skilled CNC operators, emphasizing the importance of learning these skills.

Once you grasp the basics, choose software that suits your needs. For beginners, GRBL provides a solid foundation as open-source firmware for controlling CNC machines. Notably, reports have shown that companies utilizing innovative software solutions like GRBL and advanced CAD/CAM tools experience efficiency improvements of up to 40%. Additionally, software like Fusion 360 offers comprehensive features to create and simulate CNC programs, making it an excellent tool for new users to craft their first projects. By following this guide, aspiring CNC programmers can unlock the potential of modern manufacturing technology.

Understanding Common CNC Programming Mistakes

Common Mistakes to Avoid in CNC Programming for Newbies

One of the most common mistakes beginners make in CNC programming is underestimating the importance of understanding G-codes and M-codes. These foundational codes control the machine's movement and operations, and failing to thoroughly learn their functions can lead to inefficient machining or even damage to the equipment. Newbies often rush through the learning process, which can result in poorly written programs that waste time and resources. Taking the time to master these codes will significantly enhance programming accuracy and machine performance.

Another frequent error is neglecting to validate and dry-run the program before actual machining. Many novices are eager to see their work come to life and may skip crucial testing steps. This oversight can lead to catastrophic results; a simple mistake in the code can cause the CNC machine to crash, damaging both the tool and the workpiece. It is essential to utilize simulation software or perform a dry run to visualize the tool path without engaging the actual machine. By developing a habit of validating their programs, beginners can avoid costly mistakes and cultivate a more systematic approach to CNC programming.

Related Posts

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

-

Understanding CNC Controllers: Revolutionizing Precision Manufacturing with 30% Higher Efficiency