Top 10 Benefits of Using CNC Turning Machines for Precision Manufacturing

In the realm of precision manufacturing, CNC turning machines have emerged as indispensable tools that enhance efficiency and accuracy across various industries. According to a recent report from the International Federation of Robotics, the sector has seen a staggering increase in the adoption of CNC technologies, with projections indicating a 10% annual growth rate by 2025. This shift underscores the industry's commitment to optimizing manufacturing processes, minimizing waste, and improving product quality, all of which are critical in today’s competitive landscape.

Experts like Dr. Emily Carter, a renowned mechanical engineer and authority in CNC technologies, emphasize the transformative power of CNC turning machines. She stated, "The precision and flexibility offered by CNC turning not only streamlines production but also significantly reduces the time from concept to market." As industries strive for greater innovation and adaptability, the role of CNC turning machines becomes even more vital in achieving these goals.

Utilizing CNC turning machines allows manufacturers to produce complex geometries with high precision and repeatability. This capability is pivotal in sectors such as aerospace, automotive, and medical devices, where the margin for error is exceedingly slim. In this article, we will explore the top 10 benefits of using CNC turning machines for precision manufacturing, illustrating how they can shape the future of production efficiency and quality.

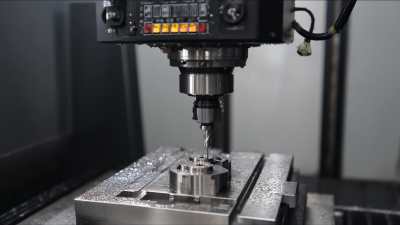

Understanding CNC Turning Machines: An Introduction to Precision Manufacturing

CNC turning machines are revolutionizing precision manufacturing through advanced digital technologies. These machines enhance productivity across various industries by providing exceptional accuracy and repeatability. The CNC tool grinders market is projected to grow at a 6.3% CAGR through 2034, highlighting the rising demand for high-precision tooling. As manufacturers increasingly adopt these technologies, they can achieve tighter tolerances and improved surface finishes, which are critical in sectors such as aerospace, automotive, and electronics.

Additionally, the global precision engineering machines market is anticipated to expand significantly, with a size expected to reach around USD 29.16 billion by 2034, up from USD 20.09 billion in 2025. This growth underscores the need for efficient and reliable machining solutions, which CNC turning machines provide. Events showcasing advancements in one-hit machining technologies further reflect the industry's commitment to innovation and optimization in production processes. As these machines become more prevalent, they play a crucial role in shaping the future of manufacturing, ensuring that businesses can meet rising industry standards and consumer demands effectively.

Key Advantages of CNC Turning: Enhancing Efficiency and Accuracy

CNC turning machines have revolutionized precision manufacturing by enhancing both efficiency and accuracy. According to the 2021 Manufacturing Technology Trends Report, manufacturers that implemented CNC technologies observed a remarkable 25% increase in production output while simultaneously reducing waste by up to 30%. This substantial improvement can be attributed to the automated processes of CNC turning, which minimizes the risks associated with human error, ensuring each piece is manufactured with precise specifications.

Moreover, CNC turning allows for complex geometries that are difficult to achieve through traditional machining methods. Industry studies indicate that up to 40% of businesses have reported a reduction in lead times due to the reliability of CNC operations. This not only boosts productivity but also enables manufacturers to respond swiftly to market demands, maintaining a competitive edge. The integration of such advanced machinery leads to higher-quality outputs, driving customer satisfaction and fostering long-term business relationships in an increasingly demanding marketplace.

Top 10 Benefits of Using CNC Turning Machines for Precision Manufacturing

This bar chart illustrates the top 10 benefits of using CNC turning machines for precision manufacturing. Each bar represents the effectiveness of each benefit, demonstrating the significant advantages that CNC technology brings to the manufacturing process.

Reducing Material Waste: How CNC Turning Machines Optimize Resource Use

CNC turning machines play a critical role in optimizing resource use and reducing material waste in precision manufacturing. Through their advanced capabilities, these machines significantly minimize excess material by utilizing exact measurements and sophisticated programming. This precision helps manufacturers avoid the common pitfalls of traditional machining processes, where inaccuracies can lead to substantial waste and elevated costs. By ensuring that only the necessary amount of material is used, CNC turning machines contribute to a more sustainable manufacturing model that aligns with the growing emphasis on circular economy principles.

The integration of emerging technologies into CNC machining further enhances its efficiency and reduces waste. Innovations such as AI-driven processes allow for continuous optimization of production cycles, ensuring that resources are used to their fullest potential. Additionally, the implementation of digital workflows for material reuse underscores the importance of integrating modern technology with sustainable practices. These advancements not only improve the operational efficiency of manufacturing but also support the shift towards greener practices, illustrating how CNC turning machines can lead the way in optimizing resource usage while addressing the urgent need for environmental responsibility.

Versatility in Production: Customizing CNC Turning for Various Applications

CNC turning machines have become a cornerstone in precision manufacturing due to their exceptional versatility in production. The ability to customize these machines allows manufacturers to adapt to various applications, from small-scale component production to large industrial parts. By programming specific parameters, operators can create intricate features and designs that cater to the unique needs of different industries, including automotive, aerospace, and medical sectors. This customization capability ensures that products meet stringent quality standards while maximizing efficiency.

Moreover, the use of CNC turning in diverse applications is bolstered by the ability to switch between different materials and finishes seamlessly. Manufacturers can produce components from metals, plastics, and composites with equal precision. This flexibility not only enhances production capabilities but also reduces lead times and operational costs. As industries continue to evolve, CNC turning machines provide the adaptive solutions necessary to meet emerging demands and trends, allowing for greater innovation in product design and functionality.

Top 10 Benefits of Using CNC Turning Machines for Precision Manufacturing

| Benefit | Description | Applications |

|---|---|---|

| Precision | CNC turning machines provide high accuracy with tight tolerances. | Aerospace, Automotive |

| Efficiency | Rapid production reduces lead times significantly. | Mass production, Furniture |

| Flexibility | Easily adapts to different designs and product changes. | Prototyping, Custom parts |

| Cost-Effectiveness | Reduces material waste and minimizes operational costs. | Construction, Manufacturing |

| Complex Geometry | Creates intricate designs that are difficult to achieve manually. | Medical devices, Aerospace components |

| Automation | Automated processes enhance productivity and repeatability. | High-volume production, Robotics |

| User-Friendly | Simplifies operation compared to manual machining. | Small shops, Startups |

| Material Variety | Compatible with various materials including metals and plastics. | Consumer goods, Automotive |

| Scalability | Easily scale production up or down based on demand. | Manufacturing, Commercial projects |

Streamlining Workflow: Integrating CNC Turning Machines in Manufacturing Processes

Integrating CNC turning machines into manufacturing processes can significantly streamline workflows by enhancing efficiency and precision. These machines are designed to automatically perform a variety of operations, reducing the need for manual intervention and thus minimizing human error. With their ability to execute complex geometries and maintain tight tolerances, CNC turning machines contribute to producing high-quality components in a fraction of the time traditional methods require. This automation allows operators to focus on more strategic tasks, ultimately leading to improved productivity across the board.

Moreover, the adoption of CNC turning technologies facilitates better resource management. By optimizing material usage and reducing waste during production, manufacturers can not only save costs but also adopt more sustainable practices. Enhanced data integration in CNC systems enables real-time monitoring and adjustments, leading to an agile manufacturing process that can quickly respond to changes in demand or design. This dynamic adaptability is vital in today’s competitive market, allowing manufacturers to keep pace with industry trends while ensuring consistent quality in their output.

Related Posts

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

What is Manufacturing Machines? A Comprehensive Guide to Industrial Equipment