What is CNC Work and How Does it Benefit Your Manufacturing Process

The landscape of modern manufacturing is undergoing a significant transformation, largely driven by advancements in Computer Numerical Control (CNC) technology. CNC work entails the automation of machine tools through controlled computer programming, enabling precision and efficiency in the fabrication of complex components. According to a report from the International Federation of Robotics, the implementation of CNC systems is projected to boost productivity in manufacturing sectors by as much as 30% over the next decade. This remarkable improvement in efficiency is associated with the ability of CNC work to reduce human error and expedite production cycles.

Moreover, the advantages of adopting CNC work extend beyond mere productivity gains. A study conducted by the Manufacturing Institute indicates that manufacturers leveraging CNC technology experience a reduction in waste and resource consumption by up to 20%, leading to not only cost savings but also enhanced sustainability in production practices. As industries increasingly seek to optimize their operations and respond to market demands more swiftly, the role of CNC work becomes ever more critical in shaping a competitive manufacturing environment. Thus, understanding the implications and benefits of CNC work is essential for manufacturers aiming to thrive in the rapidly evolving industrial landscape.

What is CNC Work? An Overview of Computer Numerical Control

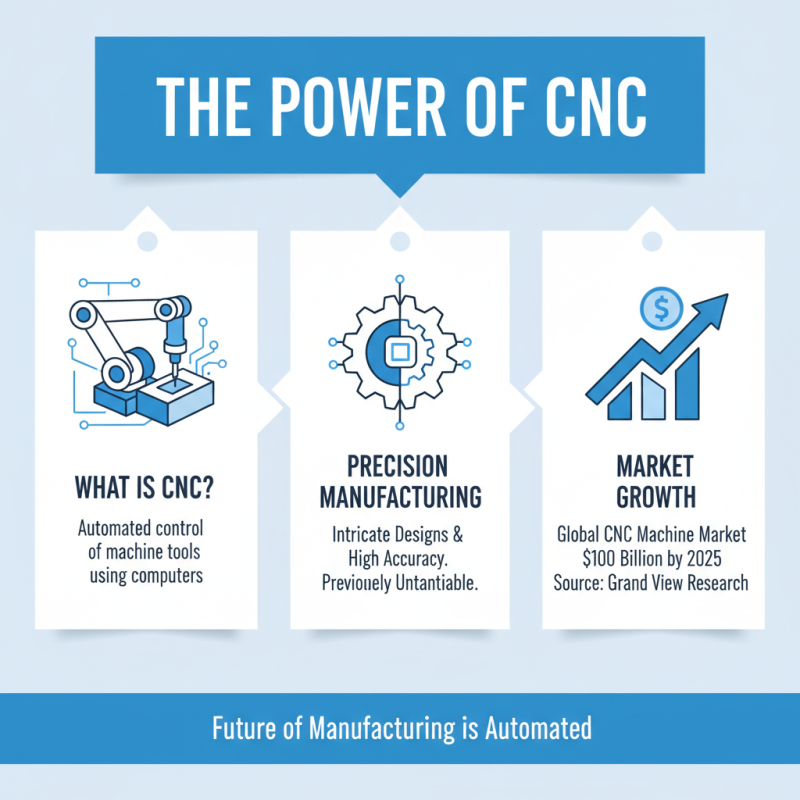

Computer Numerical Control (CNC) work refers to the automation of machine tools using computers, enabling precision manufacturing processes. This technology has revolutionized the production landscape, allowing for intricate designs and high levels of accuracy that were previously unattainable. According to a report by Grand View Research, the global CNC machine market is projected to reach $100 billion by 2025, illustrating the growing reliance on CNC technology in modern manufacturing.

CNC work involves several key components, including computer programming, machinery, and the actual workpiece. Programmers create a detailed blueprint using computer-aided design (CAD) software, which is then converted into a language that CNC machines can interpret. This process ensures that intricate designs are executed with precision, drastically reducing errors associated with manual machining. A study conducted by the Society of Manufacturing Engineers found that implementing CNC machines can increase productivity by up to 50%, demonstrating the efficiency gains potential in CNC work.

**Tips:** When considering the integration of CNC technology into your manufacturing process, start by assessing your current capabilities and determining which components could benefit the most from automation. Investing in training for your staff on CNC programming and maintenance can also maximize the potential benefits, ensuring smoother transitions and ongoing productivity improvements. Additionally, regularly reviewing equipment performance can help identify areas for further enhancement and optimization.

The Process of CNC Machining: Step-by-Step Breakdown

CNC machining is a highly precise manufacturing process that transforms raw materials into finished products using computer-controlled machinery. The process begins with the creation of a digital design using CAD (Computer-Aided Design) software. This design is then converted into a CNC program through CAM (Computer-Aided Manufacturing) software, which generates the necessary commands for the CNC machine. According to a report by Grand View Research, the global CNC machine market size was valued at approximately $71 billion in 2021 and is projected to grow at a compounded annual growth rate (CAGR) of 5.0% from 2022 to 2030, indicating a significant rise in demand for such advanced manufacturing technologies.

After the CNC program is created, the next step involves setting up the CNC machine, including selecting the appropriate tools and materials required for production. The machine is then calibrated, and the machining process begins, often involving milling, turning, or drilling operations. Each cycle is meticulously monitored to ensure high levels of precision and quality. Industry data suggests that CNC machining can enhance production efficiency by up to 75% while minimizing waste and reducing time-to-market. Such efficiencies not only drive cost savings but also improve overall manufacturing sustainability, as firms can significantly reduce their scrap rates and energy consumption during the machining process. As manufacturers increasingly adopt CNC technologies, they stand to benefit from unmatched accuracy and repeatability in production, solidifying their competitive edge in the market.

Types of CNC Machines and Their Applications in Manufacturing

CNC (Computer Numerical Control) machines have become essential components in the modern manufacturing landscape, providing precision and efficiency across various applications. Among the most common types of CNC machines are CNC mills, lathes, routers, and plasma cutters. Each type serves distinct functions: CNC mills are ideal for shaping metals and plastics, while lathes focus on creating cylindrical parts. CNC routers excel in woodworking and sign-making, whereas plasma cutters are frequently used for cutting sheet metal with high speed and accuracy.

When selecting a CNC machine for your manufacturing process, consider the specific applications you require. For instance, if you're looking to produce intricate designs or prototypes, a CNC router may be the best choice. On the other hand, for production of high precision mechanical components, a CNC mill or lathe would be more appropriate.

Tips: Always assess the materials you will be working with to select the right CNC machine, as each type has its strengths and weaknesses based on material compatibility. Additionally, investing in quality training for your operators can significantly enhance the efficiency and output quality of your CNC operations. Take the time to explore software options that can optimize machine performance and workflow integration.

Benefits of CNC Work for Efficiency and Precision in Production

CNC (Computer Numerical Control) work has revolutionized the manufacturing landscape by enhancing the efficiency and precision of production processes. One of the primary benefits of CNC technology is its ability to produce complex shapes and intricate designs with remarkable accuracy. By utilizing computer programming, CNC machines can execute precise movements, reducing the chances of human error that are often prevalent in traditional manufacturing methods. This level of precision is particularly advantageous for industries requiring tight tolerances and exact specifications.

Moreover, CNC work significantly boosts production efficiency. Automated processes enable manufacturers to produce parts and products at a much faster rate compared to manual techniques. Once a design is inputted into the system, CNC machines can operate continuously, minimizing downtime and streamlining the workflow. This efficiency not only leads to higher output but also allows businesses to meet fluctuating market demands more effectively. Overall, the integration of CNC technology into manufacturing processes sets a new standard for production capabilities, emphasizing the importance of both precision and operational efficiency.

Challenges and Considerations in Implementing CNC Technology

The implementation of CNC (Computer Numerical Control) technology in manufacturing processes offers significant advantages, but it is not without its challenges. One of the primary considerations is the initial investment required for CNC machinery and software. While these costs can be offset by the efficiency and precision gained over time, smaller manufacturers may find it difficult to allocate sufficient resources upfront.

Another challenge lies in the need for skilled personnel. Operators must be well-trained not only to run CNC machines but also to troubleshoot issues that may arise during production. This skills gap can lead to inefficiencies if adequate training programs are not in place. Additionally, integrating CNC technology with existing workflows can pose logistical challenges, requiring adjustments to current processes and sometimes leading to temporary disruptions as teams adapt to the new system.

Ultimately, companies must carefully weigh these challenges against the potential benefits of CNC technology, such as increased accuracy, reduced waste, and enhanced production speeds. Developing strategies to address these considerations proactively can pave the way for a smoother transition and greater long-term success in adopting CNC technology.

What is CNC Work and How Does it Benefit Your Manufacturing Process - Challenges and Considerations in Implementing CNC Technology

| Dimension | Description | Benefits | Challenges |

|---|---|---|---|

| Precision | CNC machining enables high precision in manufacturing processes. | Improves product quality and reduces material waste. | Requires skilled operators and expensive equipment maintenance. |

| Automation | Automated processes allow for continuous production with minimal intervention. | Increases efficiency and throughput. | Initial setup costs are high; requires CAD/CAM software integration. |

| Versatility | CNC machines can work with various materials, including metals and plastics. | Facilitates the production of complex shapes and structures. | Requires multiple machine types for different tasks. |

| Cost Efficiency | While initial investments are high, CNC can reduce long-term operational costs. | Lower labor costs and reduced cycle times can lead to significant savings. | High dependency on technology can lead to vulnerabilities in case of system failures. |

Related Posts

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

Why Precision CNC Machining is Essential for High Quality Manufacturing

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing