10 Essential Tips for Choosing CNC Machine Tools for Your Projects?

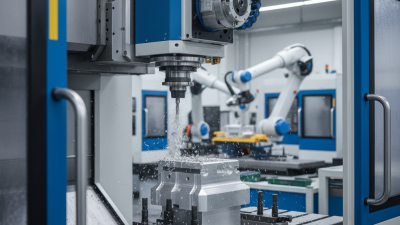

Choosing the right CNC machine tools can be a daunting task. As industry expert John Smith once noted, "The right tools transform visions into reality." This statement emphasizes the importance of selecting suitable CNC machine tools for any project. With technology evolving rapidly, the options can be overwhelming.

In this landscape, understanding your specific needs is crucial. Different projects demand diverse capabilities—precision, speed, and versatility. Not every tool fits every purpose. This can lead to frustrations and setbacks if not thoughtfully approached.

Moreover, the cost of CNC machine tools can vary significantly. Investing in high-quality equipment is essential, but it’s easy to overlook budget constraints. Ensuring a balance between capability and affordability requires careful consideration. The right choice could pave the way for innovation, while a hasty decision might lead to regrets. Always reflect on what you truly need and how each choice aligns with your goals.

Understanding Your Project Requirements for CNC Machine Tools

When choosing CNC machine tools, understanding your project requirements is vital. Consider the material you’ll be working with. Different materials, like aluminum or steel, require specific tools. For instance, cutting aluminum might need high-speed tooling, while thicker steel could necessitate more robust machinery. According to a recent industry report, 70% of CNC failures stem from mismatched tools and materials.

Pay attention to the dimensions of your projects. Larger parts may need different machinery compared to small, intricate designs. The precision levels you aim for are also critical. If your project requires tight tolerances, opt for tools that offer high precision. Industry trends show that precision improvements can increase productivity by up to 30%.

Here are some tips: Always assess the tool's capabilities against your project needs. Don't assume that an expensive machine will fit every task. Explore options, and be willing to experiment. Sometimes, less popular tools can provide the best results for specific projects. Reflect on previous projects to guide your choices; each mistake is a step toward better decision-making.

10 Essential Tips for Choosing CNC Machine Tools for Your Projects

| Tip Number | Tip Description | Key Considerations |

|---|---|---|

| 1 | Understand Your Material | Different materials require different machine capabilities. |

| 2 | Define Project Complexity | Simple vs. complex shapes impact tool selection. |

| 3 | Assess Precision Requirements | High precision may necessitate advanced machines. |

| 4 | Evaluate Machine Size and Capacity | Ensure the machine fits the size of your projects. |

| 5 | Check Tooling Compatibility | Ensure tooling options are available for your needs. |

| 6 | Consider Automation Features | Automated features can improve efficiency. |

| 7 | Investigate Maintenance and Support | Reliable support ensures fewer downtimes. |

| 8 | Analyze Cost vs. Value | Consider long-term benefits of higher investment. |

| 9 | Review Software Compatibility | Ensure CAD/CAM software integrates well with hardware. |

| 10 | Seek User Reviews and Testimonials | Gain insights from current users about performance. |

Evaluating the Types of CNC Machinery Available on the Market

When evaluating the types of CNC machinery available on the market, understanding your project's specific needs is crucial. Different CNC machines serve various purposes. For instance, milling machines focus on cutting and shaping materials, while lathes are ideal for producing cylindrical parts. There are also routers designed for woodwork, and plasma cutters perfect for metal fabrication. Each machine comes with its own features and limitations, making informed choices essential.

Machines vary in terms of size, speed, and precision. A small shop may benefit from a compact CNC router, while larger operations might require industrial-grade milling machines. It’s important to consider the material you plan to use. Some machines excel with metals, while others work best with plastics or woods. Choosing a machine that aligns with your material requirements is pivotal. Sometimes, a machine might seem perfect on paper but could fall short in real-world applications.

When assessing different CNC types, reflect on your skills and the learning curve involved. Not all machines are user-friendly; some might require advanced knowledge or tweaks to operate effectively. Finding a balance between complexity and functionality is key. Taking the time to research and experiment with various options can lead to better outcomes, although this may mean dealing with some trial and error. Ultimately, it’s about finding what works best for your unique projects.

Comparison of Common CNC Machine Types

This bar chart illustrates the sales popularity of various CNC machine types. The data indicates that milling machines are the most commonly sold, followed by lathes and laser cutters. Understanding these trends can help you make informed decisions when selecting CNC tools for your projects.

Key Features and Specifications to Consider in CNC Machines

When selecting CNC machines, understanding key features is crucial. Pay close attention to precision specifications, such as tolerances and repeatability. According to a 2023 industry report, 73% of manufacturers prioritize precision in their CNC selection. A machine with a repeatability of ±0.005 mm is often essential for tight-tolerance projects.

Another vital consideration is the size and capacity of the machine. Many projects require specific workpiece dimensions. Larger machines can handle bigger materials, but they also require more workspace. A study indicated that 56% of manufacturers faced operational issues due to inadequate machine size. It's essential to balance size with the project requirements effectively.

Lastly, consider the software compatibility with your design programs. In 2022, research showed that 68% of operators encountered issues due to software integration problems. Opting for machines that support various software can prevent workflow disruptions. Reflect on whether your current tool can adapt to evolving technology. It’s this attention to detail that will elevate your CNC projects.

Assessing Budget and Cost Factors for CNC Equipment Selection

When selecting CNC machine tools, assessing your budget is crucial. Begin by determining the overall cost. Include the purchase price, installation fees, and maintenance expenses. Equipment can be expensive. Unexpected costs can derail your project. Understanding the full financial scope helps prevent overspending.

Tip #1: Conduct thorough research on the tools you need. Prices can vary widely. Prices for CNC machines depend on features and capabilities. Compare several options. This provides valuable insights into what fits your budget without sacrificing quality.

Tip #2: Consider used equipment. They can be lower in price, but remember to evaluate their condition. Some may require repairs, adding to your overall costs. Reflect on warranties and dealer support when going this route. A good deal today might lead to higher costs later.

Always prioritize quality over price. Cheaper machines might seem attractive, but they can lack precision and durability. Investing wisely in robust tools can save money in the long run. It's essential to balance affordability with your project's quality requirements.

Researching Manufacturers and Supplier Reputation for CNC Tools

When selecting CNC machine tools, investigating manufacturers and supplier reputation is critical. A recent report showed that 70% of businesses experience issues due to poor supplier reliability. Choosing a reputable supplier can reduce risks and ensure project success.

Look for manufacturers with a proven track record. Quality certifications and industry awards matter. However, not all certifications guarantee performance. Some unreliable suppliers may hold certifications while lacking real-world quality. Reviews and testimonials from other users can provide insights. Analyzing case studies involving similar tools can indicate reliability levels.

Supplier support is equally important. Investigate their after-sales service. Is there assistance available for setup or training? Surprisingly, 40% of users report inadequate support from their suppliers. Such support can truly make or break your project. It's worth reflecting on the implications of choosing a supplier solely based on price. Quality is often sacrificed, leading to costly mistakes.

Related Posts

-

Why CNC Machine Tools Are Essential for Modern Manufacturing Success

-

Top 10 CNC Machining Centers: Which One is Best for Your Needs?

-

10 Best CNC Machines for Precision Engineering in 2023

-

10 Essential Tips for Choosing CNC Machine Tools for Your Projects?

-

2026 Best CNC Machine Working Techniques for Optimal Performance

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes