10 Essential Tips for Choosing the Right CNC Parts for Your Project

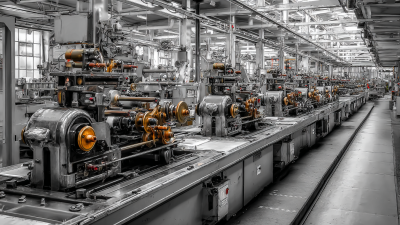

In the evolving landscape of precision engineering, selecting the right CNC parts is crucial for the success of any manufacturing project. As industry expert John Smith, a renowned CNC technology engineer, emphasizes, "The quality and compatibility of CNC parts directly impact the efficiency and accuracy of your operations." With an increasing variety of components available on the market, understanding the essentials of choosing the right parts can make the difference between a project that runs smoothly and one that falters due to incompatibility or subpar materials.

Whether you are a seasoned professional or just starting in the CNC machining world, having the right tools and components at your disposal is fundamentally important. The intricacies of CNC parts selection can be daunting, but with the right guidance, you can navigate through the options confidently. From understanding the importance of material selection to recognizing the significance of compatibility with existing machinery, these essential tips will empower you to make informed decisions that align with your project goals and enhance overall productivity.

Understanding the Role of Precision in CNC Parts Selection for Optimal Project Outcomes

Choosing the right CNC parts is crucial for achieving optimal project outcomes, as precision plays a central role in the efficiency and effectiveness of manufacturing processes. According to a report by the International Journal of Advanced Manufacturing Technology, improving precision in CNC machining can lead to a 20-30% increase in production efficiency. This statistic underscores the importance of selecting high-quality components that meet stringent tolerance requirements, which can significantly minimize errors and rework in production cycles.

Furthermore, the influence of precision extends beyond just immediate production results; it also affects the longevity and reliability of the final product. Research by the American Society of Mechanical Engineers reveals that precision-engineered CNC parts can reduce the wear and tear on machinery by up to 15%, resulting in lower maintenance costs and reducing downtime. As projects become increasingly complex, understanding the specific role each CNC component plays in the overall assembly will ensure that manufacturers achieve not only superior performance but also cost-effective solutions in their production strategies.

Evaluating Material Types: How Material Choices Impact CNC Part Performance and Longevity

When selecting CNC parts for a project, the choice of material is paramount as it directly impacts the performance and longevity of the components. According to a report by Wohlers Associates, the material used in CNC machining can affect the overall functionality of the final product, with certain materials providing superior strength, durability, and heat resistance. For instance, aluminum alloys like 6061 and 7075 are favored in aerospace applications due to their high strength-to-weight ratio and excellent corrosion resistance.

Moreover, the process of evaluating material types should consider the specific demands of the project. For example, a study published by the American Society of Mechanical Engineers (ASME) emphasizes that materials such as titanium, known for their exceptional strength and lightweight properties, are essential in high-stress environments like medical implants and automotive parts. As such, understanding the unique attributes of each material will not only optimize part functionality but also enhance the product's lifespan, ultimately leading to lower production costs and improved performance in the long run.

10 Essential Tips for Choosing the Right CNC Parts for Your Project

| Material Type | Machinability | Cost | Durability | Typical Applications |

|---|---|---|---|---|

| Aluminum | High | $$/kg | Moderate | Aerospace, Automotive |

| Steel | Moderate | $$/kg | High | Structural Components |

| Titanium | Low | $$$/kg | Very High | Medical, Aerospace |

| Plastic | High | $/kg | Low | Consumer Products, Prototypes |

| Bronze | Moderate | $$/kg | High | Bearings, Bushings |

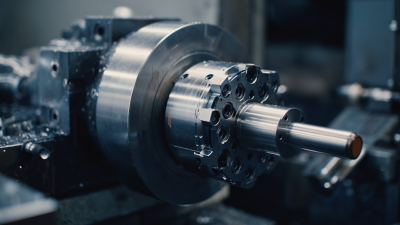

Analyzing Tolerance Requirements: Ensuring CNC Parts Meet Project Specifications and Standards

When working on a CNC project, analyzing tolerance requirements is crucial for ensuring that the parts produced meet project specifications and standards. Tolerance refers to the permissible limit of variation in a physical dimension, and it plays a significant role in the overall functionality and quality of the final product. Understanding the specific tolerances needed for your project helps you choose the right CNC parts that align with these specifications.

One essential tip when selecting CNC parts is to consult the engineering drawings meticulously. Pay close attention to the indicated tolerances, as they will guide you in selecting materials and manufacturing processes that can achieve the required precision.

Another important consideration is the capability of your CNC machine; ensure that it can handle the required tolerances without compromising on quality. Lastly, communicating with your suppliers about tolerance requirements upfront can lead to a smoother workflow, ensuring that the parts produced align perfectly with your project’s demands. Following these tips will significantly enhance the reliability and performance of your CNC projects.

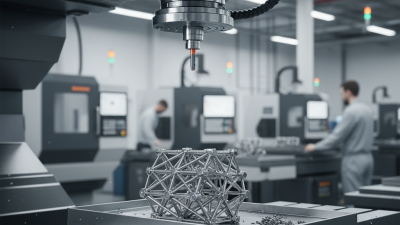

Exploring Compatibility: Choosing CNC Parts that Integrate Seamlessly with Existing Machinery

When embarking on a CNC project, ensuring compatibility between new parts and existing machinery is crucial. Studies, such as those presented in the "2022 Global CNC Market Analysis", highlight that 54% of production inefficiencies arise from mismatched equipment. Thus, evaluating the specifications and integration points of CNC parts can significantly minimize operational disruptions and enhance overall productivity.

To achieve seamless integration, it is essential to consider both the physical dimensions and the technical specifications of the components. For instance, matching spindle sizes, drive systems, and control interfaces not only facilitates easier setup but also reduces downtime. According to a report from the "CNC Parts Industry Insight" released in early 2023, projects that prioritize component compatibility see a 30% increase in operational efficiency. Therefore, engaging with manufacturers who provide comprehensive compatibility guides and support can lead to wiser investment decisions and a smoother project execution overall.

The Importance of Supplier Reputation: How Provider Reliability Affects CNC Parts Quality and Availability

When selecting CNC parts for your project, the supplier’s reputation plays a crucial role in determining both the quality and availability of components. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $117.2 billion by 2026, highlighting the increasing demand for precision and reliability in manufacturing. A reputable supplier not only ensures compliance with industry standards but also provides a consistency in quality that is vital for maintaining workflow efficiency. When a supplier is known for their reliability, customers can be confident that they will receive parts that meet stringent specifications and performance metrics.

Moreover, the availability of CNC parts directly correlates with a supplier's reliability. A survey conducted by the Association for Manufacturing Technology found that 68% of manufacturers experience disruptions due to supply chain issues, primarily linked to unreliable suppliers. By opting for providers with a solid track record, businesses can mitigate risks associated with lead times and unexpected shortages. Investigating a supplier's past performance, customer reviews, and industry certifications can provide invaluable insights, ensuring that your CNC projects are executed smoothly and effectively.

Related Posts

-

What is Manufacturing Machines? A Comprehensive Guide to Industrial Equipment

-

How to Leverage Advanced Manufacturing for Next-Generation Production Efficiency

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

-

Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

10 Essential Tips for Achieving Precision CNC Machining Success