10 Essential Tips for Achieving Precision CNC Machining Success

In the fast-evolving world of manufacturing, achieving excellence in precision CNC machining is paramount for businesses looking to remain competitive. Industry expert Dr. Emily Wang, a leading authority in CNC technology, states, "The key to success in precision CNC machining lies in not just the technology, but in the mastery of processes and continuous improvement." This insight underscores the importance of adopting best practices to enhance precision and reliability in machining operations.

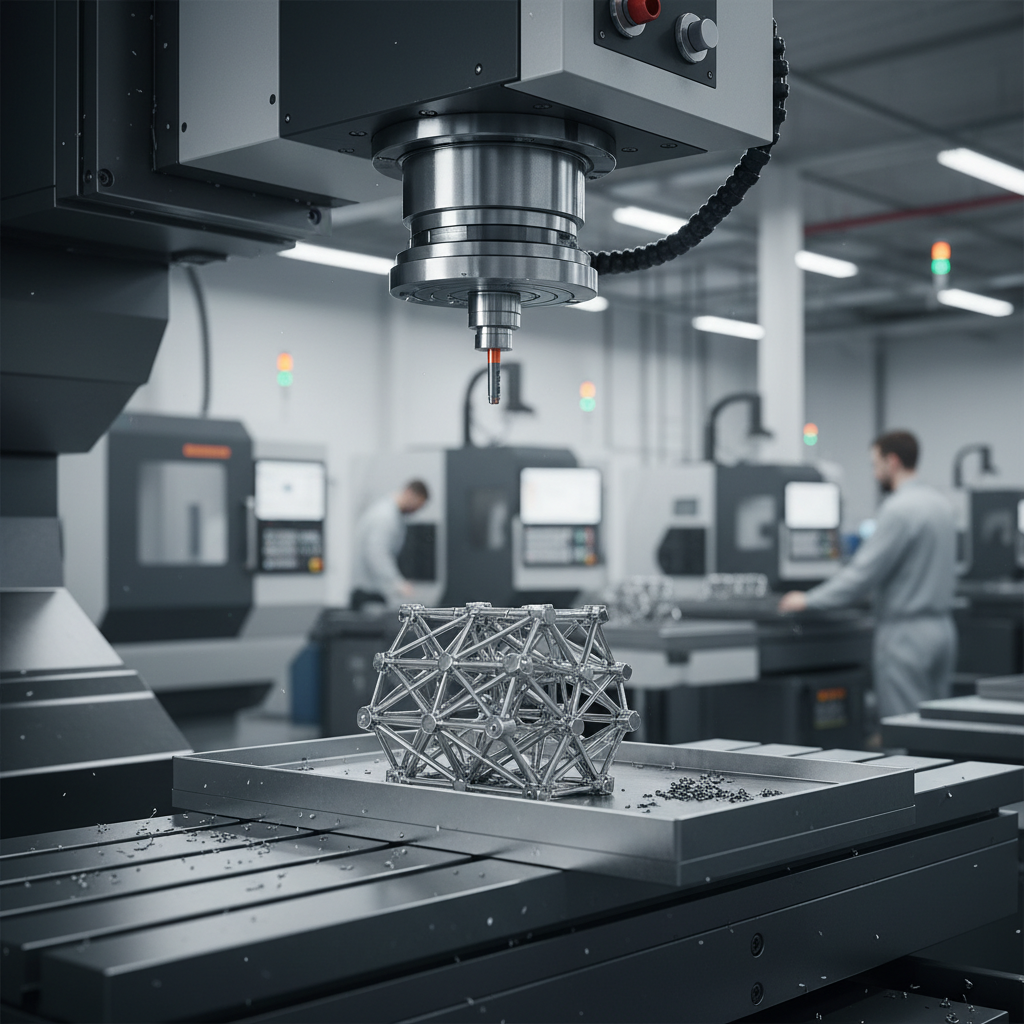

As companies strive to produce components with impeccable accuracy, understanding the intricacies of precision CNC is crucial. From choosing the right materials to employing advanced machining techniques, every decision impacts the final product quality. Adopting a strategic approach that encompasses essential tips can greatly improve machining processes and results, enabling organizations to meet and exceed industry standards.

In this article, we will explore ten essential tips for achieving precision CNC machining success. Each tip is designed to equip manufacturers with the knowledge and tools necessary to harness the full potential of CNC technology, ensuring that their creations are not only precise but also aligned with the demands of an ever-competitive market.

Understanding CNC Machining Basics for Optimal Outcomes

CNC machining is a pivotal technology in modern manufacturing, enabling high precision and efficiency. Understanding the basic principles of CNC (Computer Numerical Control) machining is essential for achieving optimal outcomes. According to the latest industry report by the National Institute of Standards and Technology (NIST), CNC machining operations can yield up to a 40% reduction in production time while enhancing dimensional accuracy to an impressive ±0.005 inches for most metals.

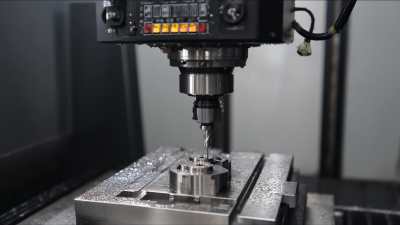

To achieve precision in CNC machining, one must prioritize proper tool selection and maintenance. Utilizing the right cutting tools tailored to the material being machined can drastically improve performance. For example, carbide tools generally outperform high-speed steel in durability and cutting efficiency, which the American Welding Society highlights in their recent report on cutting technologies.

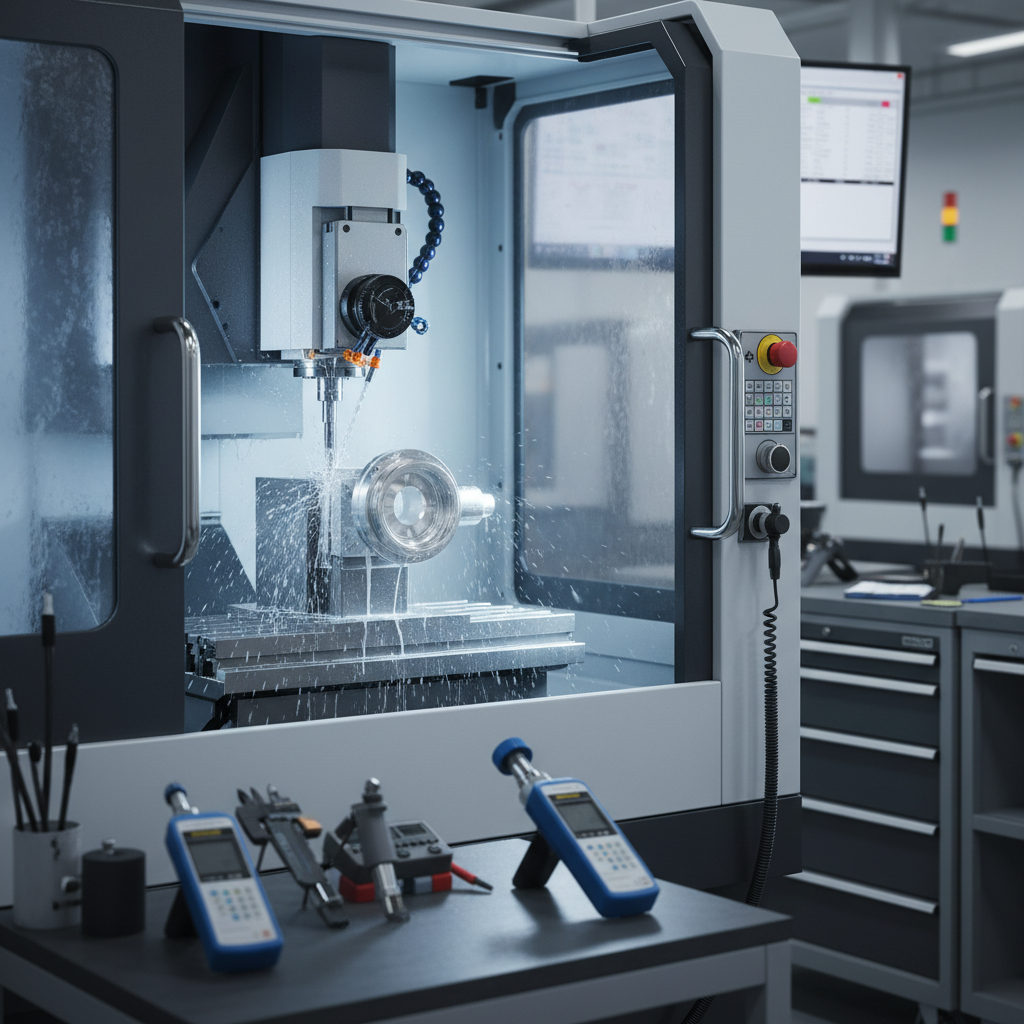

Another critical factor is the setup and calibration of CNC machines. Ensuring that the machinery is calibrated properly reduces errors commonly associated with misalignment, which can lead to significant scrap costs. Implementing regular maintenance schedules and operational checks can maintain optimal machine conditions, as suggested by the Precision Manufacturing Association, which states that well-maintained equipment can extend the life of CNC machines by up to 30%, thereby promoting long-term success in precision machining.

Choosing the Right CNC Machine and Tools for Your Projects

Selecting the right CNC machine and tools is crucial for achieving precision in machining projects. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.57 billion by 2026, indicating a robust demand for advanced machinery that meets industry standards. When choosing a CNC machine, factors such as the type of material being machined, the complexity of the parts, and production volume should be considered. For example, a CNC milling machine may be ideal for intricate work with metals, while CNC routers are better suited for softer materials like wood and plastics.

In addition to the machine itself, selecting appropriate tools is pivotal. Tool material and design significantly impact cutting performance and tool life. Research by Technavio suggests that high-speed steel (HSS) tools are increasingly favored for their blend of cost-effectiveness and durability, with advancements in coatings enhancing their performance in various machining conditions.

Furthermore, keeping abreast of emerging technologies, such as 5-axis machining, can improve precision and efficiency, reducing lead time and production costs. Thus, investing time in choosing the right CNC machinery and tooling is essential for any project aiming for excellence in precision machining.

Implementing Effective Programming Techniques for Precision Cuts

Precision CNC machining relies heavily on effective programming techniques to ensure that cuts are executed with accuracy and efficiency. The foundation of successful CNC machining begins with choosing the right software and understanding its capabilities. Properly configuring the machining parameters—such as feed rates, spindle speeds, and tool paths—is crucial. It is essential for programmers to familiarize themselves with the specific characteristics of the materials being machined, as this knowledge directly influences the machining strategies and ultimately affects the precision of the cuts.

Another significant aspect of effective programming for precision cuts is simulation. Utilizing simulation software allows programmers to visualize the machining process before actual implementation, helping to identify potential issues such as tool collisions or inefficient paths. This step not only enhances precision but also minimizes material waste and machine wear. Furthermore, incorporating post-processing techniques can streamline the code generation for CNC machines, ensuring that the final output adheres to the desired specifications. By focusing on these programming techniques, manufacturers can bolster their precision CNC machining efforts and achieve superior outcomes.

Maintaining Equipment and Tools for Consistent CNC Performance

Maintaining equipment and tools is crucial for achieving consistent performance in CNC machining, especially as the global CNC machine market continues to grow, projected to reach $195.59 billion by 2032 with a CAGR of 9.9%. Regular maintenance not only prolongs the life of machinery but also enhances precision and efficiency in production processes. Proper care routines, including lubrication, calibration, and the timely replacement of worn tools, can drastically reduce downtime and lead to better operational results.

Furthermore, the woodworking CNC tools market reflects similar patterns of growth, expected to rise from approximately $8.2 billion in 2025 to $13.4 billion by 2035, with a CAGR of 5.0%. This trend highlights the increasing reliance on high-quality CNC tools in various applications. Effective tool management, which includes the use of precision tools for cutting, drilling, and milling, is imperative for maintaining high standards of work. As demand for high-precision machining continues to rise, ensuring that tools and equipment are in top condition will be a key factor for success in the industry.

10 Essential Tips for Achieving Precision CNC Machining Success

| Tip No. | Tip Description | Frequency of Maintenance | Expected Outcome |

|---|---|---|---|

| 1 | Regularly inspect and clean cutting tools | Before each use | Enhanced tool life and precision cuts |

| 2 | Calibrate CNC machines regularly | Monthly | Increased accuracy and reduced errors |

| 3 | Use quality coolant and lubricants | Every shift | Better surface finish and reduced friction |

| 4 | Monitor and adjust feed rates | Every project | Optimized machining efficiency |

| 5 | Check for backlash in the machine | Quarterly | Improved positioning accuracy |

| 6 | Keep the workspace clean and organized | Daily | Safety and efficiency boost |

| 7 | Verify tool setup before machining | Each setup | Minimized error and scrap |

| 8 | Schedule regular machine overhauls | Annually | Extended machine lifespan |

| 9 | Train staff on equipment use and safety | Bi-annually | Increased operational safety |

| 10 | Document and analyze machining processes | Per project | Continuous improvement in performance |

Quality Control Measures to Ensure Accurate Machining Results

In the realm of precision CNC machining, stringent quality control measures are pivotal to ensuring accurate machining results. Implementing comprehensive quality management systems, such as statistical process control and regular calibration of tools, can significantly reduce variances in production. These systems help in identifying defects early in the process, allowing for prompt corrective actions and ensuring that the final products meet specified tolerances.

Moreover, fostering a culture of continuous improvement among the workforce is crucial. Training programs that emphasize the importance of quality control, alongside regular assessments of machining techniques, can enhance employees' skills and awareness around precision. The integration of advanced technologies, such as digital calipers equipped with digital displays, further aids in achieving high levels of accuracy by providing real-time measurements during the machining process.

This multifaceted approach not only preserves the integrity of the machining outputs but also positions manufacturers to meet the evolving demands of the industry effectively.

Related Posts

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

Top 10 Benefits of Using CNC Turning Machines for Precision Manufacturing