What is Manufacturing Machines? A Comprehensive Guide to Industrial Equipment

Manufacturing machines play a crucial role in the modern industrial landscape, serving as the backbone of production across various sectors. According to a report by IBISWorld, the manufacturing machinery industry is projected to grow steadily, reaching a market size of over $50 billion in the next five years. This growth is fueled by advancements in technology and automation, which have significantly increased the efficiency and precision of manufacturing processes. Moreover, the rise of smart manufacturing and Industry 4.0 has further highlighted the importance of integrating manufacturing machines into contemporary production lines.

In today’s competitive environment, manufacturers are increasingly relying on sophisticated machinery to enhance productivity and reduce operational costs. A survey conducted by the National Association of Manufacturers (NAM) suggests that over 80% of manufacturing firms consider automation and advanced manufacturing technologies as key factors in improving their competitiveness. As we delve into this comprehensive guide, we will explore the various types of manufacturing machines, their applications, and the latest innovations shaping the industry. Understanding these elements is essential for any business aiming to optimize its manufacturing capabilities and stay ahead in the ever-evolving market.

What are Manufacturing Machines? Understanding the Basics

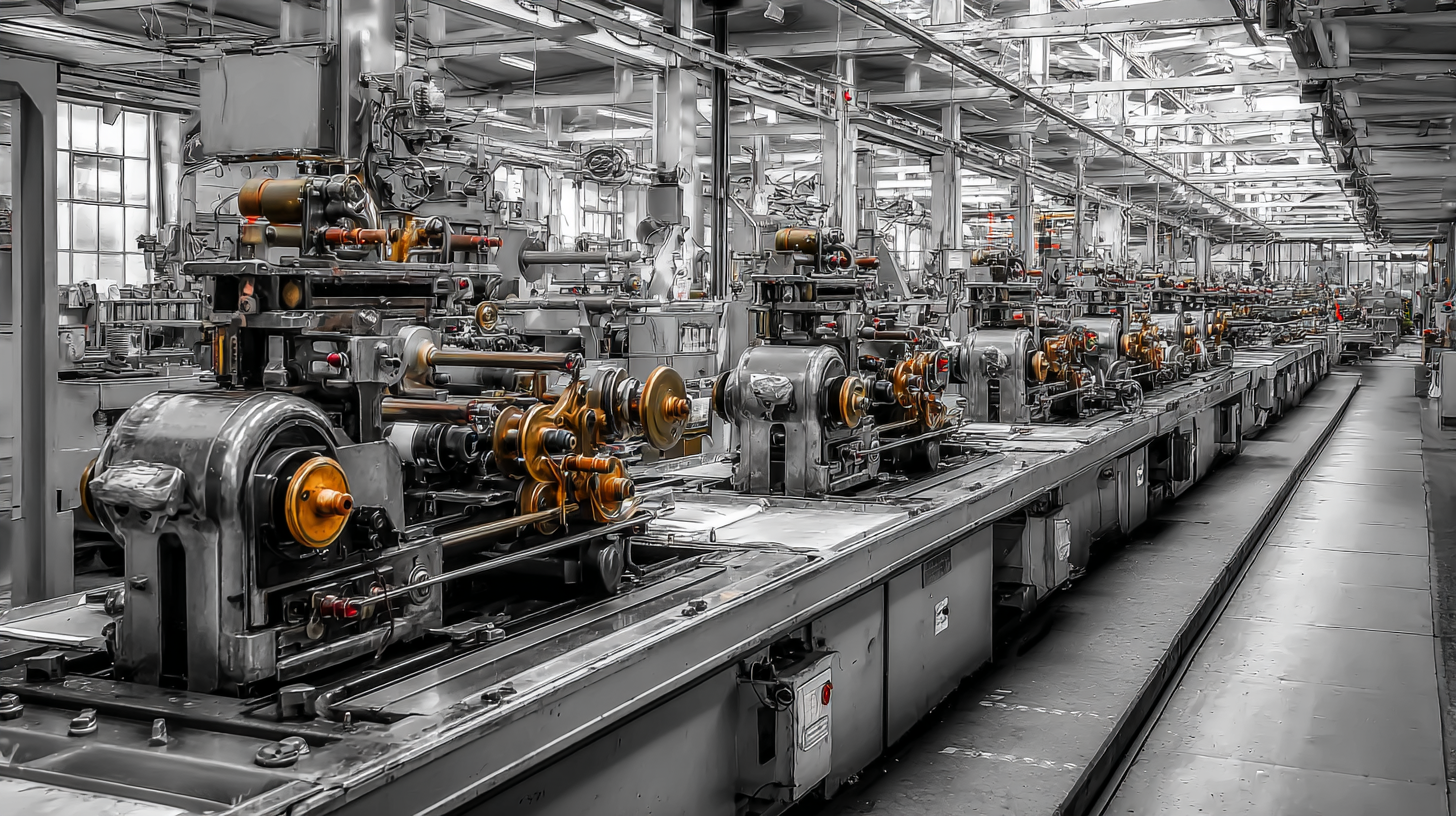

Manufacturing machines play a crucial role in modern industrial processes, as they encompass a wide range of equipment used to produce goods efficiently. Understanding the basics of these machines is essential for anyone involved in manufacturing. They vary from simple tools to complex machinery, each designed to perform specific tasks, such as cutting, shaping, or assembling materials.

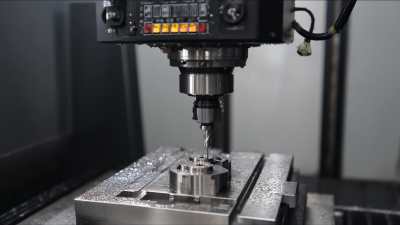

When working with advanced software like Fusion 360, post processors become an integral part of the manufacturing process. These specialized programs translate the designs created in the software into machine-readable instructions, allowing the manufacturing equipment to execute precise movements. This ensures that the final product meets the specifications defined by the designer.

Tips: Always choose the right post processor for your specific machine to ensure compatibility and efficiency. Additionally, regularly update your software and post processor settings to incorporate the latest features and improvements. Familiarizing yourself with the machine's capabilities and limitations can also help you optimize your design for successful manufacturing outcomes.

Key Types of Manufacturing Machines in 2025

Manufacturing machines are essential in the production processes across various industries. As we look towards 2025, we can identify several key types of manufacturing machines that are set to dominate the landscape, particularly in China, which is becoming the largest market for industrial robots. The integration of advanced robotics in manufacturing facilities not only streamlines production but also addresses the growing demand for automation and efficiency.

In the realm of manufacturing, industrial robots will play a crucial role, enabling increased productivity and precision. As the production scale continues to expand, it is projected that China will account for a significant portion of global robot output. Additionally, significant investments in smart manufacturing technologies and innovations will further enhance equipment efficiency and output quality.

Tip: Keep an eye on trends such as the increasing reliance on AI and automation in manufacturing machines; they are likely to shape the industry's future. Another important consideration is the growing emphasis on sustainability in manufacturing practices, urging companies to adopt more environmentally friendly technologies. Embracing these advancements can provide a competitive edge in an increasingly automated marketplace.

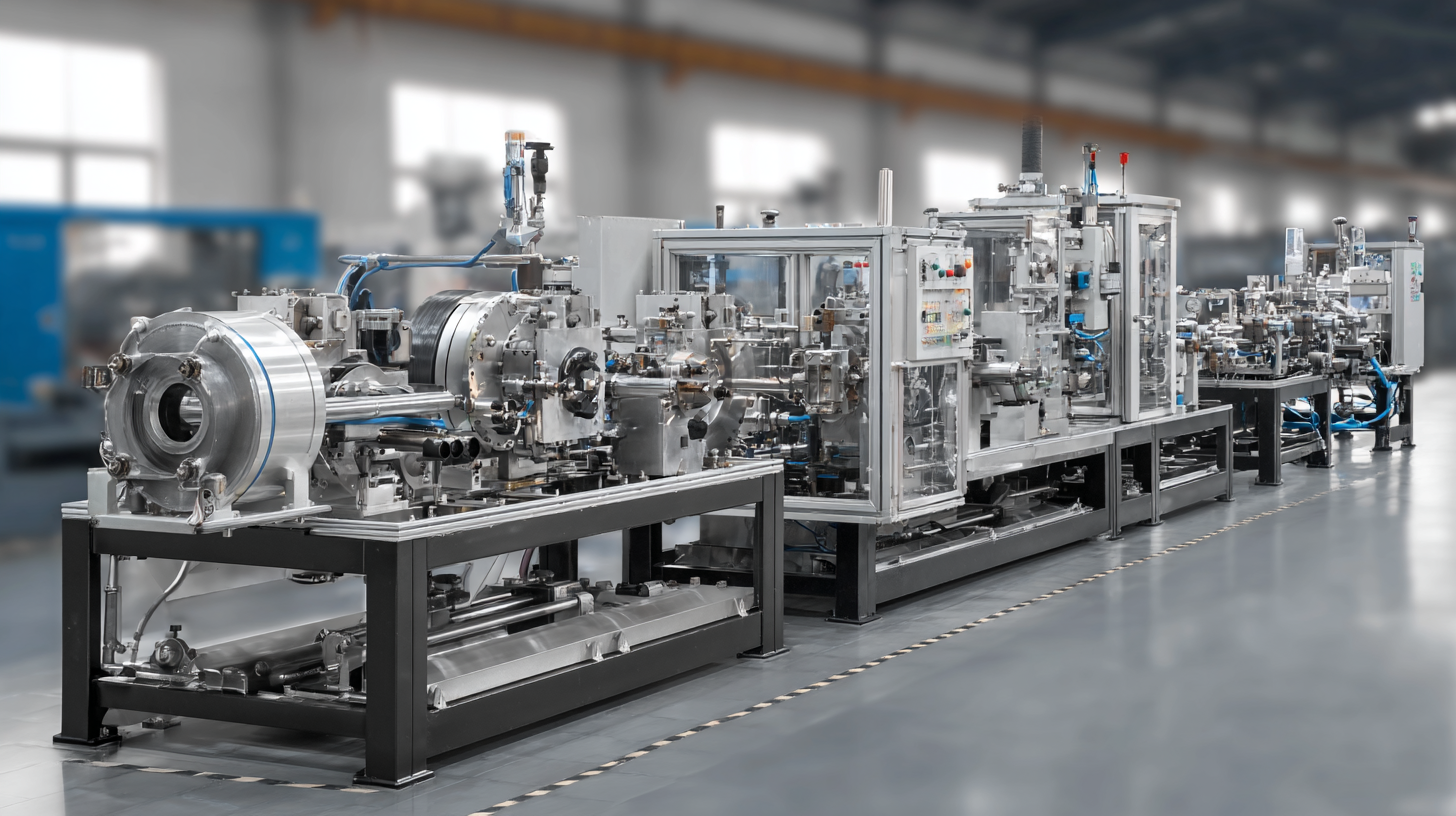

Innovations Shaping the Future of Industrial Equipment

Innovations in manufacturing machines are driving the future of industrial equipment, reshaping how businesses operate and enhancing efficiency. According to a report by MarketsandMarkets, the industrial automation market is projected to reach $296.70 billion by 2026, growing at a CAGR of 9.2% from 2021. This growth is fueled by advancements in smart manufacturing technologies, including the Internet of Things (IoT), artificial intelligence (AI), and robotics. These technologies enable manufacturers to achieve higher levels of precision, reduce waste, and streamline operations.

Additionally, the adoption of additive manufacturing techniques, commonly known as 3D printing, is revolutionizing traditional manufacturing processes. A study by Wohlers Associates found that the global 3D printing market was valued at $12.6 billion in 2020 and is expected to surpass $35 billion by 2025. This shift not only allows for more customized production but also significantly reduces lead times and costs associated with traditional manufacturing methods. As manufacturers continue to integrate these innovations, the landscape of industrial equipment will evolve, fostering a new era of productivity and sustainability.

Top 5 Manufacturing Machines to Watch in 2025

In the rapidly evolving landscape of manufacturing,

technological advancements continue to reshape the industry. As we look towards 2025,

several manufacturing machines are poised to lead the way in efficiency, innovation, and productivity.

Among these, robotic automation systems stand out as

crucial players, providing flexibility and precision that meet the increasing demand for customized products.

These machines can handle complex tasks with speed and accuracy, reducing labor costs while enhancing

production capabilities.

Essential Factors in Choosing the Right Manufacturing Equipment

When selecting the right manufacturing equipment, several essential factors must be considered to ensure efficiency and productivity. First, understanding the specific needs of your production process is crucial. This includes evaluating the materials you will be working with, the volume of production required, and the desired outcome of the manufacturing process. Each type of equipment has its strengths and is designed for particular applications, so aligning your equipment choice with your operational goals is imperative.

Additionally, factors such as budget, space constraints, and maintenance requirements play a significant role in the decision-making process. It's essential to establish a clear budget that not only covers the initial purchase but also includes long-term operational costs, such as energy consumption and maintenance. Space limitations in your facility can influence the type and size of machinery you can realistically accommodate. Lastly, consider the equipment's reliability and the availability of support and spare parts, which can greatly impact your production efficiency and overall workflow.

What is Manufacturing Machines? A Comprehensive Guide to Industrial Equipment

| Machine Type | Key Features | Typical Applications | Considerations |

|---|---|---|---|

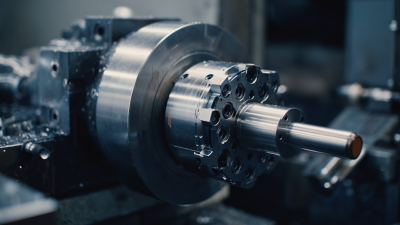

| CNC Machine | Precision control, multi-axis operations | Metalworking, woodworking, prototyping | Initial setup cost, skill level for operation |

| Injection Molding Machine | High-speed production, repeatable precision | Plastic parts manufacturing, complex shapes | Material costs, mold design expenses |

| 3D Printer | Layered manufacturing, rapid prototyping | Prototyping, custom parts, medical applications | Material limitations, print speed |

| Laser Cutting Machine | High precision, versatile material compatibility | Metal, fabric, and other material cutting | Operator safety, maintenance requirements |

| Lathe Machine | Rotational operations, various tooling options | Metal shaping, drilling, threading | Space requirements, operator expertise |

Related Posts

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections

-

Understanding CNC Controllers: Revolutionizing Precision Manufacturing with 30% Higher Efficiency