What is Manufacturing Machines and How They Transform Production Processes

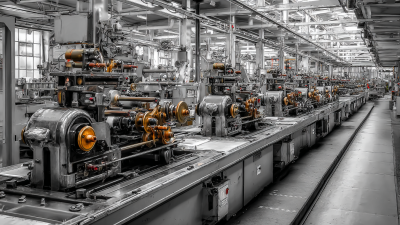

In the rapidly evolving landscape of industrial production, manufacturing machines play a pivotal role in shaping operational efficiency and driving innovation. According to a report by the International Federation of Robotics, global sales of industrial robots reached an impressive 384,000 units in 2020, highlighting a significant trend towards automation and advanced manufacturing technologies. These machines, ranging from CNC machines to automated assembly equipment, are transforming traditional production processes, enhancing precision, reducing labor costs, and increasing output rates.

Moreover, a study by McKinsey & Company indicates that the integration of manufacturing machines can lead to productivity gains of up to 20-25% in various sectors. This advancement is not merely a matter of replacing human labor but involves a synergistic approach where skilled operators work alongside intelligent machines, optimizing workflows and minimizing errors. As industries continue to adopt these technologies, the demand for innovative manufacturing solutions is only expected to grow, underscoring the importance of understanding manufacturing machines and their impact on the future of production. Through their capabilities, manufacturing machines are not only revolutionizing existing processes but also enabling companies to adapt to market shifts and consumer demands more effectively.

What Are Manufacturing Machines? An Overview of Definitions and Types

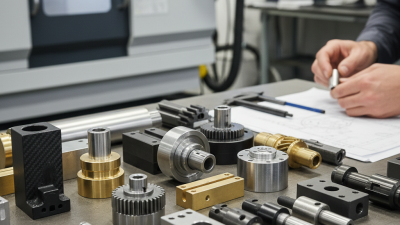

Manufacturing machines are essential tools that facilitate the production process across various industries. They can be defined as mechanical devices specifically designed to perform tasks in manufacturing, such as cutting, shaping, assembling, and finishing materials. These machines can range from simple hand-operated tools to complex automated systems, each serving a distinct purpose tailored to specific production requirements.

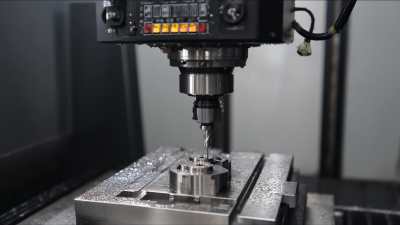

There are several types of manufacturing machines, each categorized based on their function and technology. Traditional machines include lathes, milling machines, and drills, which rely on manual operation and mechanical principles. In contrast, modern manufacturing has witnessed the rise of automation and robotics. Computer Numerical Control (CNC) machines, for instance, represent a significant advancement, allowing for precise, repeatable, and efficient production processes.

Additionally, additive manufacturing technologies, such as 3D printing, have revolutionized how products are designed and created, enabling rapid prototyping and customization. Each type of manufacturing machine plays a crucial role in enhancing productivity and driving innovation within the manufacturing landscape.

The Role of Automation in Modern Manufacturing Processes

Automation plays a crucial role in modern manufacturing processes, revolutionizing the way products are created and delivered. According to a report by McKinsey, automation can increase productivity by 20-25% in the manufacturing sector, enabling companies to produce higher quantities of goods with lower labor costs. This shift has not only enhanced efficiency but also improved accuracy and reduced waste, allowing manufacturers to meet consumer demands more effectively. By integrating robotics and advanced software systems, facilities can operate around the clock with minimal human supervision, significantly optimizing operations.

Moreover, the implementation of automation technologies has been shown to lead to enhanced flexibility in production lines. A study from the International Federation of Robotics indicates that industrial robots have increased global productivity by 40% over the past decade, allowing manufacturers to adapt swiftly to changing market conditions and consumer preferences. Additionally, automation facilitates better quality control by utilizing data analytics and machine learning to predict failures and reduce defects. As manufacturers continue to embrace these advanced technologies, they are not only enhancing their operational capabilities but are also setting new standards for innovation and efficiency in the industry.

What is Manufacturing Machines and How They Transform Production Processes - The Role of Automation in Modern Manufacturing Processes

| Machine Type | Functionality | Efficiency Improvement (%) | Automation Level | Typical Applications |

|---|---|---|---|---|

| CNC Machine | Precision cutting and shaping | 30-50% | High | Aerospace, automotive |

| 3D Printer | Additive manufacturing | 25-40% | Medium | Prototyping, custom parts |

| Robotic Arm | Material handling and welding | 45-70% | Very High | Assembly lines, electronics |

| Injection Molding Machine | Mass production of plastic parts | 20-30% | High | Consumer goods, automotive |

| Laser Cutting Machine | High precision cutting of materials | 35-55% | High | Metal fabrication, aerospace |

Impact of Manufacturing Machines on Production Efficiency and Output

Manufacturing machines play a pivotal role in modern production processes, significantly enhancing efficiency and output. By automating repetitive tasks and streamlining operations, these machines minimize human error and speed up production times. For instance, advanced machines like CNC (Computer Numerical Control) tools and robots can operate consistently at high speeds with precision, allowing manufacturers to produce complex parts that would be difficult or impossible to achieve manually. This automation not only boosts productivity but also enables companies to meet increasing market demands effectively.

The impact of manufacturing machines on production efficiency is evident in various sectors. With the introduction of technologies such as 3D printing and additive manufacturing, businesses can quickly prototype and produce goods with less material waste and reduced lead times. Furthermore, the integration of smart technology and data analytics into manufacturing processes allows for real-time monitoring and optimization of operations. This leads to better resource allocation and enhanced decision-making, ultimately resulting in higher output levels and lower costs. As industries continue to embrace these innovations, the transformation of production processes will only intensify, setting new standards for efficiency and quality in manufacturing.

Impact of Manufacturing Machines on Production Efficiency and Output

Key Statistics on Manufacturing Machine Adoption and Industry Growth

The manufacturing sector is currently witnessing a significant transformation driven by the adoption of advanced manufacturing machines. Key statistics indicate that more than 70% of manufacturers are now investing in automation technologies, reflecting a shift towards increased efficiency and productivity. As industries embrace these innovations, they report a substantial reduction in operational costs, with many organizations achieving cost savings of up to 30%. This trend is not only enhancing production capabilities but also enabling manufacturers to scale their operations more effectively in a competitive landscape.

Tips: When considering the implementation of manufacturing machines, it is essential first to assess your current production processes. Identifying bottlenecks or inefficiencies will help maximize the benefits of automation. Additionally, invest in employee training to ensure that your workforce is equipped to work alongside new technologies, fostering a smoother transition and greater overall productivity.

Another noteworthy aspect is the projected growth rate of the manufacturing machinery market, anticipated to reach a hefty 8% annually over the next five years. This robust growth is accompanied by a rise in job creation within the sector, as businesses look to employ skilled workers who understand modern manufacturing technologies. Engaging with industry trends and forecasts will provide valuable insights for businesses looking to stay ahead of the curve in adopting manufacturing machines.

Future Trends: Innovations in Manufacturing Machines and Their Potential Effects

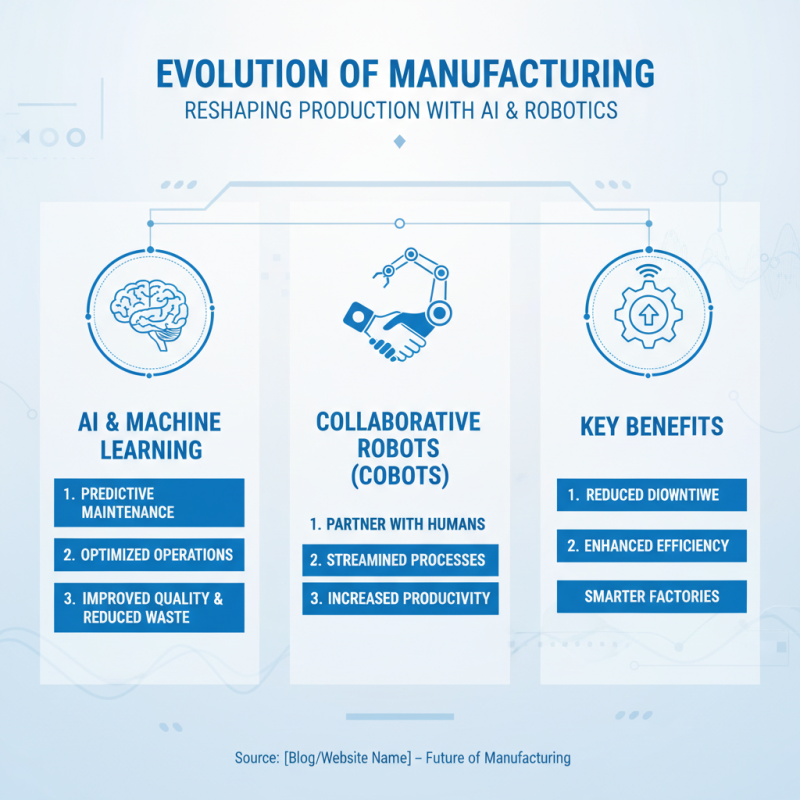

The evolution of manufacturing machines is being driven by groundbreaking innovations that promise to reshape production processes across various industries. One of the most significant trends is the integration of artificial intelligence and machine learning into manufacturing machines. This technology allows for predictive maintenance, reducing downtime and enhancing efficiency. By analyzing data in real-time, manufacturers can optimize their operations, leading to improved product quality and reduced waste. Additionally, collaborative robots, or cobots, are emerging as valuable partners on the factory floor, working alongside human workers to streamline processes and increase overall productivity.

Another key trend is the advancement of additive manufacturing, commonly known as 3D printing. This technology enables the production of complex designs that were previously unfeasible with traditional manufacturing methods. As 3D printing techniques improve, they are expected to reduce material costs and lead times significantly while allowing for greater customization of products. Moreover, the adoption of smart manufacturing systems, incorporating the Internet of Things (IoT), empowers machines to communicate and share data seamlessly. This connectivity not only enhances operational transparency but also facilitates real-time decision-making, paving the way for more agile and responsive manufacturing environments. These innovations collectively promise to transform manufacturing into a more efficient, flexible, and environmentally responsible sector.

Related Posts

-

What is Manufacturing Machines? A Comprehensive Guide to Industrial Equipment

-

Understanding CNC Controllers: Revolutionizing Precision Manufacturing with 30% Higher Efficiency

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

10 Essential Tips for Choosing the Right CNC Parts for Your Project

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques