How to Optimize Plastic CNC Machining for Better Precision and Efficiency

The importance of optimizing plastic CNC machining has never been more critical in today's manufacturing landscape, where precision and efficiency can significantly impact product performance and overall operational costs. According to a recent report by Grand View Research, the global CNC machining market is projected to reach $117.93 billion by 2027, with plastic CNC machining becoming an increasingly vital segment due to its ability to produce intricate parts with high tolerances and minimal waste. This growing demand necessitates a thorough examination of techniques and strategies that enhance both precision and efficiency.

As noted by industry expert Dr. Emily Tran, a leading figure in CNC machining technology, "The future of manufacturing lies in our ability to refine processes that allow for not just faster production, but also enhanced accuracy. Optimizing plastic CNC machining is essential to meeting the evolving needs of the industry." By leveraging advanced technologies and innovative methods, manufacturers can reduce cycle times and improve the quality of their plastic components, ensuring they remain competitive in an ever-changing market.

With the continued advancement of CNC machining tools and techniques, focusing on optimization strategies will not only improve precision but also lead to significant cost savings and increased production capabilities. It is crucial for manufacturers to stay informed about best practices and industry developments that drive the optimization of plastic CNC machining, ultimately fostering a more sustainable and efficient production environment.

Understanding CNC Machining Basics for Plastics: A Comprehensive Overview

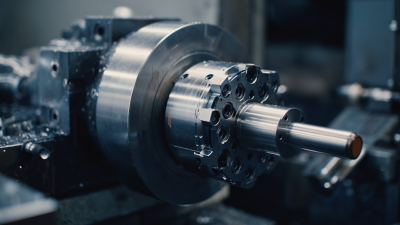

CNC machining is a critical process in the manufacturing of plastic components, combining precision with efficiency. Understanding the basics of CNC machining is vital for optimizing production. At its core, CNC (Computer Numerical Control) machining involves the use of computer programs to control machine tools, allowing for highly accurate cuts and shapes in various plastics. This process offers significant advantages over manual machining, including repeatability, speed, and the ability to produce complex geometries with minimal human intervention.

When working with plastics, several factors influence the machining process. Material selection is paramount, as different plastics exhibit distinct behaviors when cut, milled, or drilled. For instance, softer plastics may require slower spindle speeds to prevent melting, while harder materials may necessitate higher speeds with appropriate cooling methods. Additionally, the choice of cutting tools and their geometries can significantly affect the surface finish and dimensional accuracy of the final product. By understanding these basic principles, manufacturers can effectively tailor their CNC machining processes to enhance efficiency and achieve better precision in their plastic components.

Optimization of Plastic CNC Machining: Precision vs. Efficiency

Key Factors Influencing Precision in Plastic CNC Machining Processes

When it comes to optimizing plastic CNC machining, several key factors significantly influence precision in the machining processes. One of the most critical factors is the selection of the right tooling and cutting parameters. According to a recent industry report by the Society of Manufacturing Engineers, the choice of tooling material and geometry can reduce machining errors by up to 25%. Utilizing advanced coating technologies for tools can enhance wear resistance, leading to a more consistent finished product. Additionally, adjusting feed rates and spindle speeds based on the specific type of plastic being processed allows for improved surface finish and tighter tolerances.

Another vital aspect affecting precision is machine calibration and maintenance. Regular calibration ensures that the CNC machine is operating within the desired specifications, directly impacting repeatability and dimensional accuracy. A study published in the Journal of Manufacturing Science and Engineering indicates that improper calibration can lead to dimensional deviations of up to 15%, adversely affecting overall product quality. Furthermore, the environmental conditions during machining, such as temperature and humidity, can influence the material properties of plastics. Maintaining stable conditions can prevent warping and dimensional changes, thereby enhancing the precision of the final parts produced.

How to Optimize Plastic CNC Machining for Better Precision and Efficiency

| Key Factors | Influence on Precision (%) | Impact on Efficiency (%) | Typical Range |

|---|---|---|---|

| Material Quality | 30 | 25 | High-grade plastic |

| Tool Condition | 25 | 20 | Well-maintained tools |

| CNC Machine Calibration | 35 | 30 | Periodic checks |

| Feed Rate | 20 | 35 | Optimal speed ranges |

| Cooling System Efficiency | 10 | 15 | Consistent temperature |

Techniques to Enhance Efficiency and Reduce Cycle Times in CNC Machining

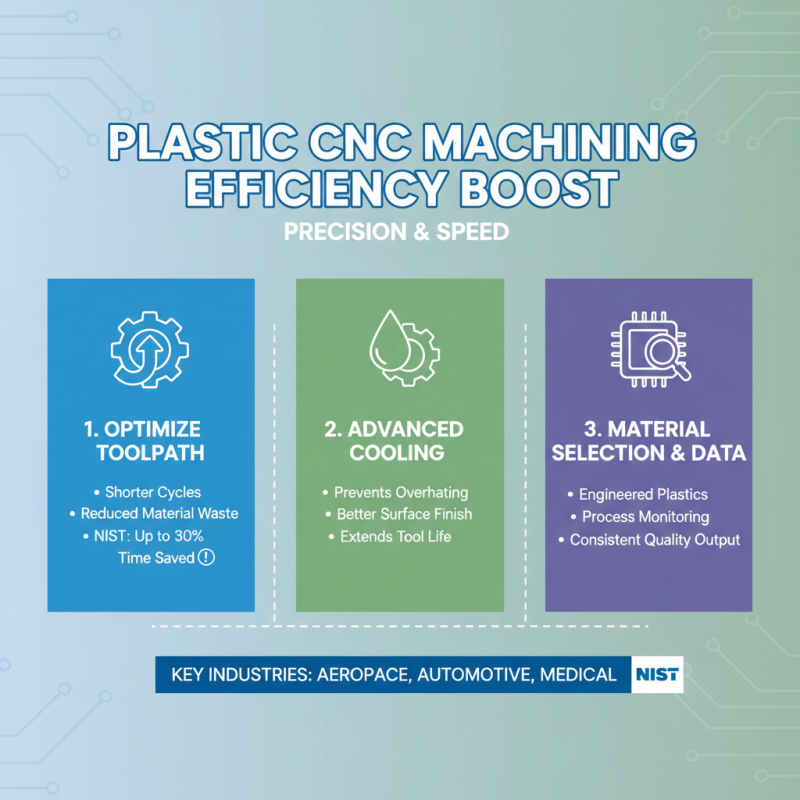

In the realm of CNC machining, particularly with plastic materials, enhancing efficiency while maintaining precision is crucial. According to a report by the National Institute of Standards and Technology (NIST), optimizing CNC machining processes can result in up to a 30% reduction in cycle times. Implementing innovative techniques not only boosts operational efficiency but also ensures high-quality output, essential in industries such as aerospace, automotive, and medical devices.

Adopting advanced tooling strategies is one method to minimize cycle times. Utilizing high-speed cutting tools and optimized feeds can significantly improve the material removal rate. For example, switching to carbide tooling can increase tool life by 50% while lower friction coefficients improve speed. Additionally, adjusting the coolant application to where it reduces thermal deformation can further enhance precision during the machining process.

**Tips:** Regularly monitor and recalibrate CNC machines to ensure they are operating within optimal parameters. Training machine operators on the latest technologies and machining techniques can also lead to improved efficiency and skill development, fostering a culture of continuous improvement within manufacturing environments. Implementing these techniques can substantially contribute to the overall productivity of CNC operations, especially in high-demand sectors.

Material Selection: Impact on Precision and Machining Performance

Material selection plays a crucial role in optimizing plastic CNC machining, directly impacting both precision and overall machining performance. Different plastics exhibit varying physical properties, which can influence the outcome of the machining process. For instance, while some materials may provide excellent surface finishes, others may cause more wear on cutting tools, leading to less precision over time. Understanding the material's characteristics, such as rigidity, thermal stability, and wear resistance, is essential in making informed decisions to enhance accuracy and efficiency.

Tips: When choosing materials, opt for those with low thermal expansion coefficients to maintain dimensional stability during machining. Additionally, consider using plastics specifically formulated for CNC applications, as these can lead to improved performance and extended tool life. It's also advisable to perform a thorough analysis of the material's machinability rating to ensure optimal settings are selected for speed, feed rate, and tool type.

Moreover, the thickness and density of the plastic material can greatly affect how components are machined. Thicker materials may require more power and time to process, impacting the overall efficiency of the machining operation. By selecting the appropriate thickness for the specific application, manufacturers can strike a balance between structural integrity and performance.

Tips: Always test the selected material on a smaller scale before full-scale production to identify any potential machining challenges. This proactive approach can save time and reduce waste, ensuring a smoother CNC machining process overall.

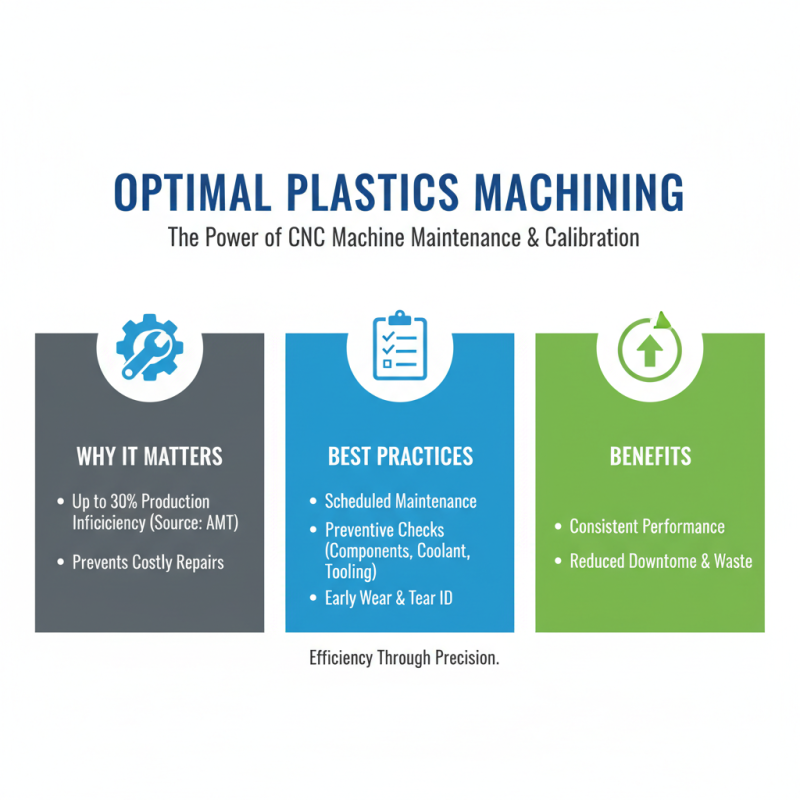

Best Practices for Maintenance and Calibration of CNC Machines for Plastics

Regular maintenance and calibration of CNC machines are essential to ensure optimal performance when machining plastics. According to a report by the Association for Manufacturing Technology, improper calibration and maintenance can lead to production inefficiencies of up to 30%. This highlights the importance of adhering to best practices, such as creating a scheduled maintenance routine that includes preventative checks on machine components, coolant systems, and tooling alignment. Identifying wear and tear early can prevent unexpected downtime and costly repairs, enabling a more efficient workflow in production environments.

Furthermore, precision in CNC machining greatly depends on accurate calibration of machinery. The International Society of Automation emphasizes that a well-calibrated machine can yield tolerances as tight as ±0.01 mm, which is critical in industries requiring high precision, such as aerospace and medical device manufacturing. Regular calibration checks, ideally every few months or before significant production runs, can help maintain these precision standards. It is recommended to use standardized calibration tools and procedures, ensuring the CNC machine operates at its optimal capabilities and produces consistent quality parts, ultimately improving overall productivity.

Related Posts

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

-

Why Precision CNC Machining is Essential for High Quality Manufacturing

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Understanding CNC Controllers: Revolutionizing Precision Manufacturing with 30% Higher Efficiency

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

What is Manufacturing Machines? A Comprehensive Guide to Industrial Equipment