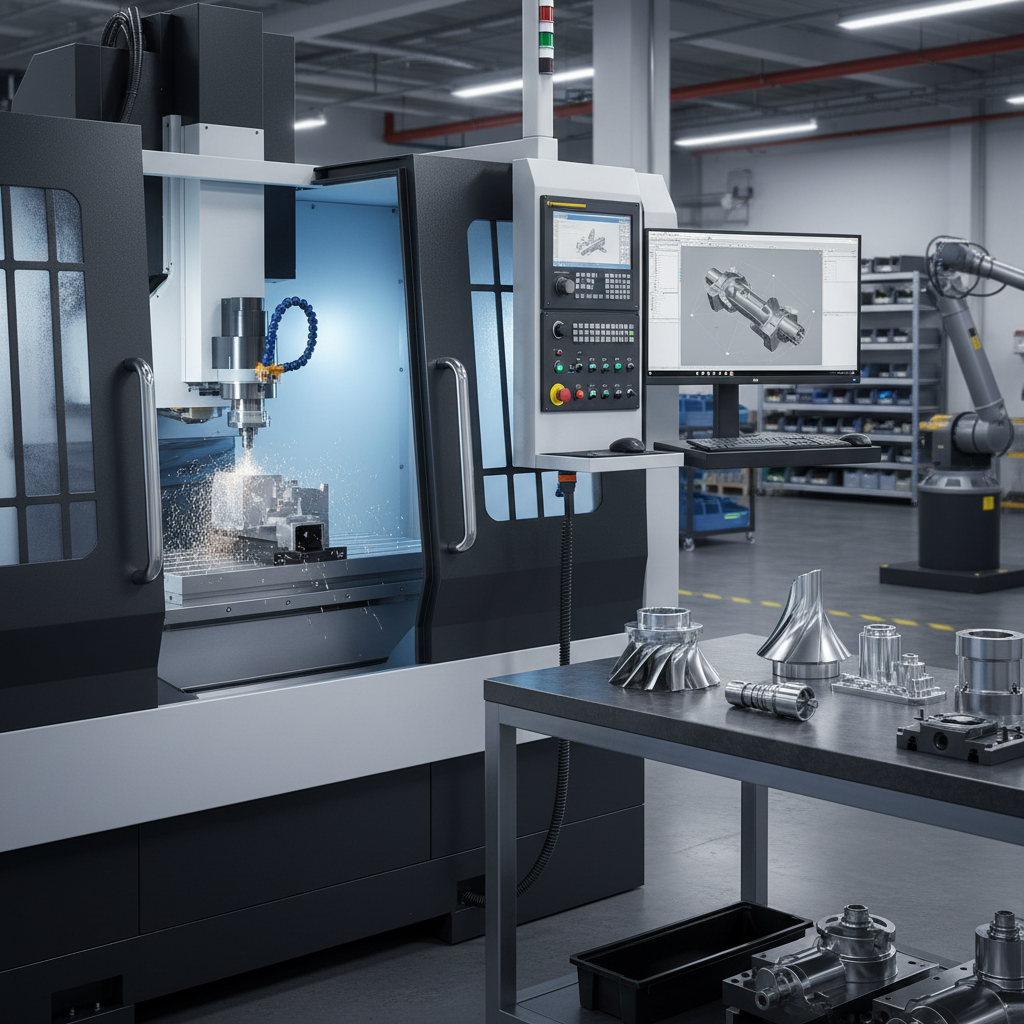

Why Precision CNC Machining is Essential for High Quality Manufacturing

In the rapidly evolving landscape of modern manufacturing, the significance of precision CNC machining cannot be overstated. As industries strive for higher quality, reduced lead times, and improved scalability, precision CNC machining has emerged as a cornerstone of high-quality manufacturing processes. According to a report by Grand View Research, the global CNC machining market is expected to reach a staggering USD 100 billion by 2025, driven by the increasing demand for customized, intricate parts across various sectors, including aerospace, automotive, and medical devices.

Precision CNC machining enables manufacturers to achieve tolerances as tight as ±0.001 inches, ensuring that each component meets stringent quality standards. This level of accuracy not only enhances the performance and durability of finished products but also significantly reduces waste and operational costs. Moreover, with advancements in technology, such as 3D printing integration and advanced CAD/CAM systems, the capability of precision CNC machining continues to expand, offering innovative solutions that are vital for staying competitive in today’s market.

As businesses look toward 2025 and beyond, embracing precision CNC machining will be essential for achieving operational excellence and delivering high-quality products that meet evolving consumer demands.

The Importance of Precision CNC Machining in Modern Manufacturing Processes

Precision CNC machining plays a pivotal role in modern manufacturing processes, where the demand for high-quality standards has never been greater. The integration of advanced digital manufacturing technologies has revolutionized industries by enhancing productivity. By allowing for greater accuracy and efficiency, these technologies ensure that every component meets stringent specifications, thereby reducing waste and minimizing errors in production.

Furthermore, innovations in tube cutting technology exemplify how precision engineering can transform manufacturing. This advancement facilitates precise cuts that maintain the integrity of materials, essential for applications where tolerances are critical. Combined with cutting and welding technologies, manufacturers can now harness the power of automation and ultra-high precision to meet the challenges of smart manufacturing. As automation continues to prevail, the reliance on precision CNC machining will only strengthen, ensuring that products not only meet but exceed quality expectations in a competitive market.

Key Metrics: Accuracy and Tolerance Levels Achieved by CNC Machining

Precision CNC machining is a cornerstone of high-quality manufacturing, known for its ability to achieve remarkable accuracy and tight tolerance levels. This technology allows manufacturers to create complex parts with precision that traditional machining methods struggle to match. The key metrics of accuracy and tolerance are vital in determining the quality and functionality of finished products, especially in industries such as aerospace and medical device manufacturing, where even the slightest deviation can lead to significant issues.

Tips for enhancing accuracy in CNC machining include regular maintenance of machinery and calibration of tools. Ensuring that your CNC equipment is well-maintained can help avoid discrepancies in product dimensions. Additionally, utilizing advanced software features for simulation can allow manufacturers to visualize potential inaccuracies before physical production begins, thereby minimizing waste and ensuring tighter tolerances.

Another important tip is to train your operators appropriately. Skilled machinists who understand the intricacies of CNC programming can better manipulate settings to improve precision. Furthermore, implementing a robust quality control process that includes inspecting parts at critical stages can lead to early detection of any deviations from specified tolerances, ultimately ensuring high-quality output in your manufacturing processes.

Industry Applications: Where Precision CNC Machining Makes a Difference

Precision CNC machining plays a vital role in various industries by providing the high accuracy and quality required for modern manufacturing processes. In sectors such as aerospace, automotive, and medical equipment, the need for finely-tuned components that meet stringent specifications is paramount. The ability of CNC machines to produce intricate parts consistently and efficiently has revolutionized production lines, allowing manufacturers to scale operations while maintaining precision.

The market for CNC machining services is projected to grow significantly, driven by the increasing demand for customized solutions across diverse applications. Industries are actively seeking precision manufacturing capabilities to enhance product performance and reduce waste. As companies strive for innovation and efficiency, the integration of advanced CNC technologies becomes integral. This shift not only highlights the importance of high-quality manufacturing but also underscores the potential for future growth in the precision CNC machining sector, as evidenced by the expected increase in market size for related industries in the coming years.

Importance of Precision CNC Machining in Various Industries

Cost Efficiency: How CNC Machining Reduces Waste and Increases Profit Margins

CNC machining is revolutionizing the manufacturing sector by significantly enhancing cost efficiency. By prioritizing precision, companies can minimize waste and streamline production processes. The ability of CNC machines to execute tasks accurately the first time reduces material wastage, thereby increasing profit margins. Recent market reports suggest a growing demand for CNC metal cutting tools, underscoring the industry's shift towards methods that promote efficiency and sustainability.

Tips for maximizing cost-efficiency in CNC machining include regularly maintaining machinery to ensure optimal performance and investing in high-quality tooling that lasts longer and reduces downtime. Additionally, implementing digital twin technologies can bridge the gap between real and virtual operations, allowing manufacturers to simulate processes and identify inefficiencies before they impact production.

Incorporating smart technologies like AI into CNC operations can also drive substantial cost savings. AI’s ability to analyze data and optimize workflows leads to more informed decision-making, enabling manufacturers to sustain a competitive edge while minimizing operational costs. Embracing these advancements is crucial for businesses aiming to thrive in the ever-evolving landscape of high-quality manufacturing.

Trends and Innovations: The Future of Precision CNC Machining in Manufacturing

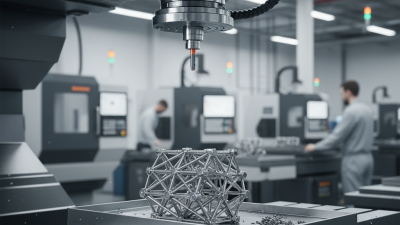

The future of precision CNC machining in manufacturing is being shaped by several key trends and innovations that enhance efficiency and quality. One significant development is the integration of advanced automation and robotics into CNC machining processes. These technologies not only streamline production but also reduce human error, resulting in consistently high-quality parts. As manufacturers increasingly adopt smart factories, data analytics plays a crucial role in optimizing machining operations, enabling real-time monitoring and predictive maintenance.

Another trend is the rise of additive manufacturing techniques being combined with traditional CNC machining. This hybrid approach allows for greater design flexibility and the ability to produce complex geometries that were previously unattainable. Moreover, advancements in materials science are leading to the development of high-performance materials that can withstand extreme conditions, further expanding the applications of precision CNC machining in industries such as aerospace and medical devices. As manufacturers continue to embrace these innovations, precision CNC machining will remain essential for meeting the ever-evolving demands for high-quality products in a competitive market.

Related Posts

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

10 Essential Tips for Achieving Precision CNC Machining Success

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications