Top 10 CNC Machining Centers: Which One is Best for Your Needs?

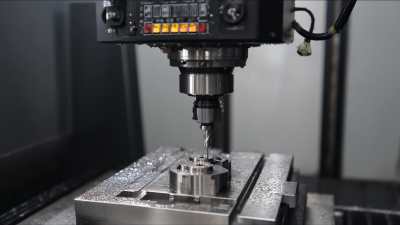

When it comes to precision manufacturing, the choice of a CNC machining center can significantly influence the quality and efficiency of production processes. These advanced machines have revolutionized the manufacturing landscape, allowing for intricate designs and tight tolerances to be achieved with ease. As industries continue to evolve, the demand for versatile and reliable CNC machining centers has surged, prompting manufacturers to offer an extensive range of options tailored to diverse applications.

In this article, we will explore the top 10 CNC machining centers available on the market today. Each model brings unique features and capabilities that cater to specific needs, whether you are working in aerospace, automotive, or general manufacturing. By comparing the systems, their specifications, and applications, we aim to assist you in identifying which CNC machining center best aligns with your operational requirements and production goals.

Whether you are a seasoned machinist or a new entrant in the field, understanding the nuances of each model will empower you to make an informed decision for your future projects.

Understanding CNC Machining Centers and Their Applications

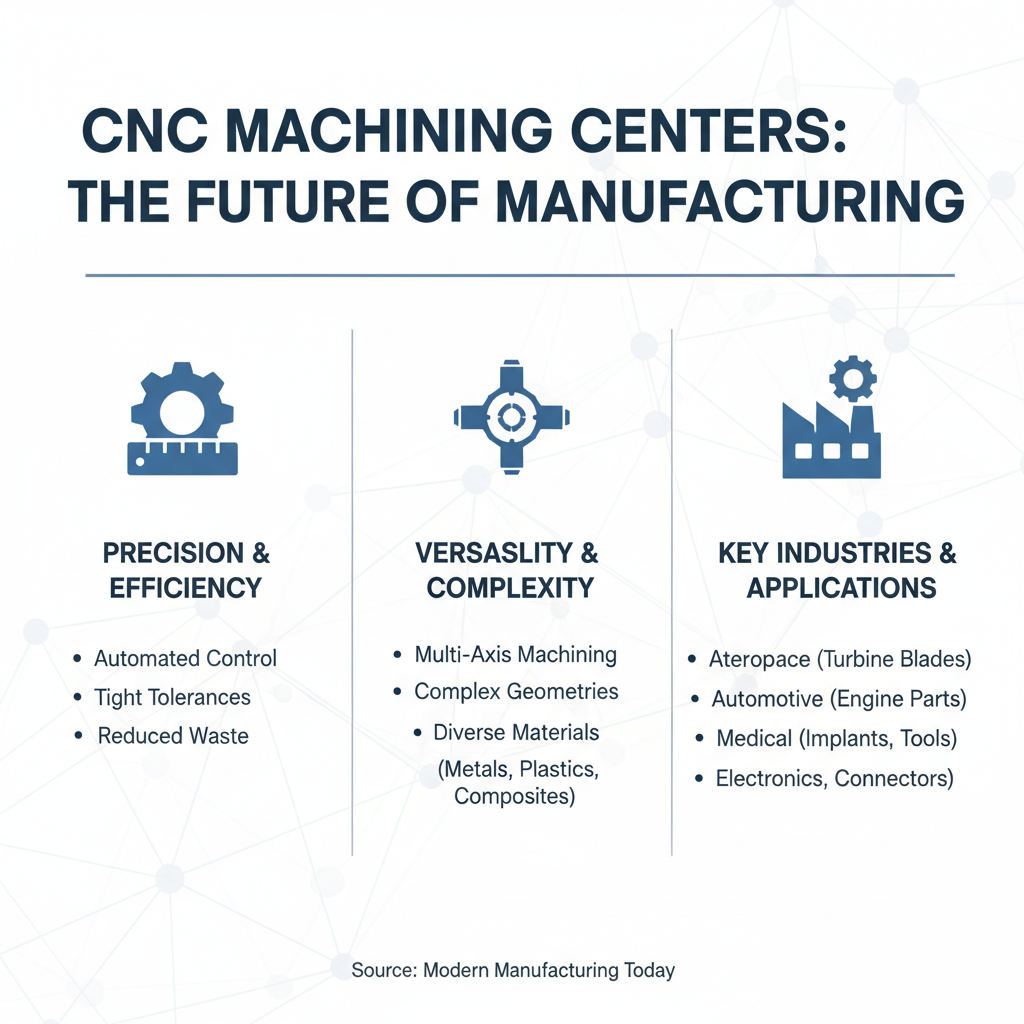

CNC (Computer Numerical Control) machining centers play a crucial role in modern manufacturing, combining precision, efficiency, and versatility. They allow for automated control of machining tools, which is essential for producing complex parts in various industries, including aerospace, automotive, and medical equipment. Understanding the different types of CNC machining centers and their applications helps manufacturers choose the right equipment to meet specific production needs.

As the CNC machine market continues to expand, projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, the integration of advanced technologies such as hybrid manufacturing techniques and augmented reality is becoming increasingly important. These innovations not only enhance production processes but also streamline training and improve error reduction. Choosing the right CNC machining center not only involves considering the type of machining required but also the capabilities of modern technology that can optimize performance and output.

Key Factors to Consider When Choosing a CNC Machining Center

When selecting a CNC machining center, several key factors should be considered to ensure it meets your specific needs. First, precision and efficiency are paramount; the right machine should deliver high accuracy while optimizing production time. According to industry reports, the global market for machining centers was valued at approximately $29.17 billion in 2018, with an expected compound annual growth rate (CAGR) of 4.9% leading up to 2032. This growth can be attributed to an increasing demand for advanced manufacturing solutions that can handle intricate tasks in various sectors, including the rapidly expanding lithium battery production market.

Another critical aspect to consider is the environmental impact of the machines. As manufacturers shift towards more sustainable practices, it is essential to evaluate the operational efficiency and eco-friendliness of potential CNC solutions. Machines that integrate automation and energy-efficient technologies not only reduce waste but also enhance overall productivity. With the significant rise in demand within the lithium battery equipment sector, driven by the expansion of the battery market itself, choosing a CNC machining center that aligns with these advancements can position your operations for future success.

Top 10 CNC Machining Centers: Performance Comparison

This chart compares the speed, precision, and versatility of the top 10 CNC machining centers available in the market. It highlights key performance metrics that can help you choose the best CNC machining center for your specific needs.

Overview of the Top 10 CNC Machining Centers Available Today

When considering the best CNC machining centers available today, it's essential to assess the features, capabilities, and intended applications of each model. Many leading brands have developed machines suited for various needs, ranging from prototyping to full-scale production. Some top contenders excel in precision and speed, making them ideal for industries like aerospace and automotive, where tolerances are critical and turnaround times are tight.

Moreover, user-friendly interfaces and advanced software integration are becoming staples in modern CNC machining centers. These enhancements allow operators to streamline workflows and improve productivity. As companies increasingly seek to enhance their operational efficiency, selecting a machine that not only fits their technical specifications but also integrates seamlessly into existing processes becomes a crucial factor. By examining the strengths and weaknesses of each option, businesses can make informed decisions to optimize their machining capabilities.

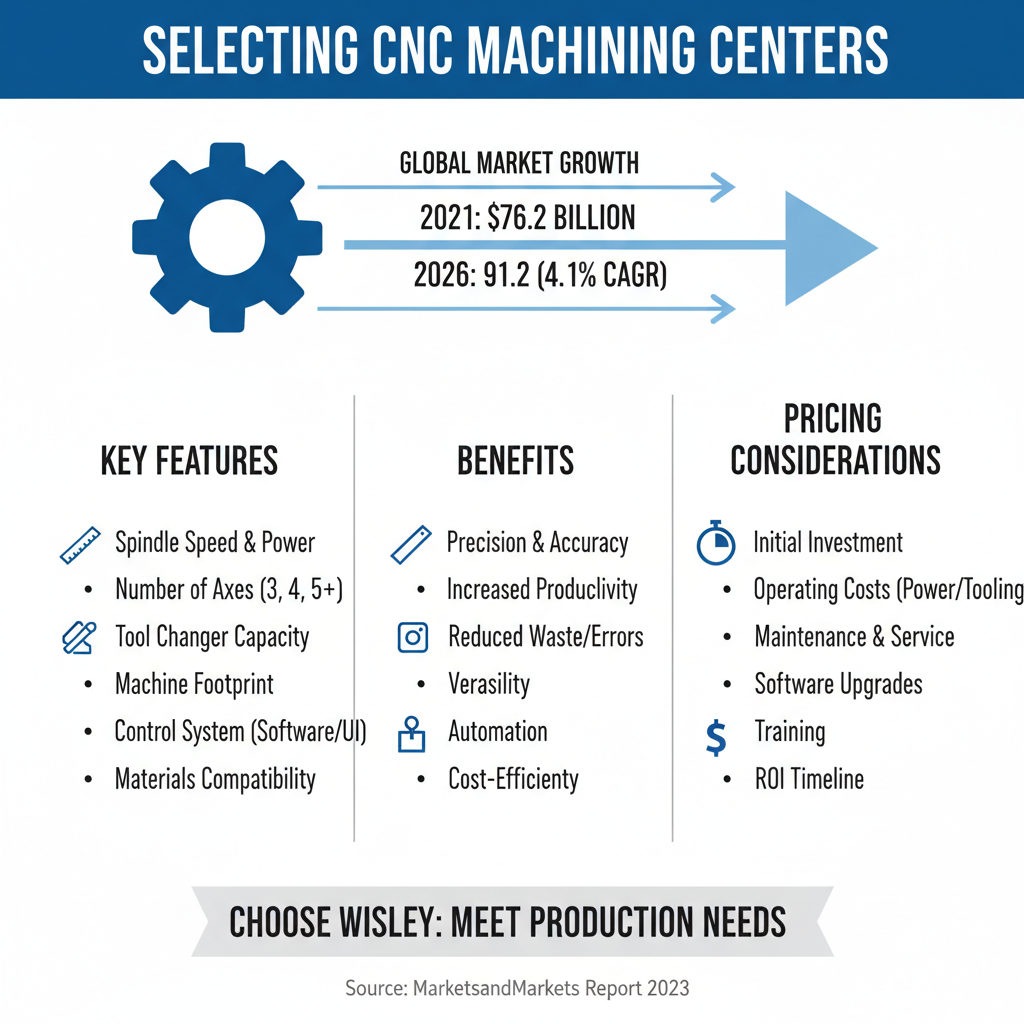

Comparative Analysis: Features, Benefits, and Pricing of Each Model

When considering the best CNC machining centers, a comparative analysis of features, benefits, and pricing is essential for determining the right model to meet specific production needs. According to a recent report by MarketsandMarkets, the global CNC machine market is expected to grow from $76.2 billion in 2021 to $91.2 billion by 2026, reflecting an annual growth rate of around 4.1%. This growth indicates a robust demand for diverse machining capabilities, emphasizing the importance of selecting a center that caters to unique operational requirements.

Each model in the top 10 list offers distinct advantages. For instance, the XYZ 123 features a user-friendly interface and high-speed spindle options, making it ideal for intricate designs and quick turnaround times. Meanwhile, the Alpha CNC 450 stands out for its superior rigidity and thermal stability, which enhances precision for heavy-duty applications.

Pricing is another critical factor; while some models may come at a premium, their long-term reliability and lower maintenance costs can justify the initial investment. Industry reports suggest that leveraging advanced CNC technology can lead to operational efficiencies, often resulting in a 20-30% reduction in production time. Therefore, carefully weighing these aspects is crucial for making an informed decision that aligns with specific business goals.

User Reviews and Experiences: Which CNC Machining Center Prevails?

User reviews play a crucial role in determining the best CNC machining center for various needs. Many users emphasize the importance of reliability and precision in their experiences, highlighting that even minor discrepancies can lead to significant production losses. For instance, a user who invested in a high-end milling machine praised its exceptional repeatability, stating that it has transformed their workflow.

Other reviewers have shared experiences with more budget-friendly options, noting how these machines still managed to meet their specific requirements, especially for small-scale projects.

Moreover, customer support and ease of use are frequently mentioned factors in user experiences. Users appreciate manufacturers that provide comprehensive training and support, which can significantly enhance their productivity. One reviewer remarked on how a robust technical support network reduced downtime, enabling their team to resolve issues promptly.

Collectively, these insights help prospective buyers navigate their choices, ensuring they invest in a CNC machining center that aligns well with their operational demands and budget constraints.

Related Posts

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections

-

Top 10 Benefits of Using CNC Turning Machines for Precision Manufacturing