Top CNC Lathe Machines in 2025: Features, Benefits, and Buying Guide

As we look toward the future of manufacturing in 2025, the significance of CNC lathe machines continues to rise at an unprecedented rate. According to a recent industry report by MarketsandMarkets, the global CNC machine market is expected to reach USD 100 billion by 2025, driven by the growing demand for precision engineering across various sectors such as automotive, aerospace, and electronics. CNC lathe machines, with their ability to produce intricate parts with high accuracy and consistency, play a pivotal role in this transformation.

The advancements in technology over the past few years have greatly enhanced the performance and capabilities of CNC lathe machines. Features such as automated tool changers, advanced control systems, and integrated software have made these machines indispensable in modern workshops. Moreover, the benefits of CNC lathes, including reduced labor costs, improved production speed, and minimized material waste, align perfectly with the evolving needs of manufacturers striving for operational efficiency.

Understanding the features and advantages of CNC lathe machines is essential for businesses looking to invest wisely in this technology. With the right information at hand, manufacturers can make informed purchasing decisions that will drive their productivity and competitiveness in a rapidly advancing industrial landscape. In this guide, we will explore the top CNC lathe machines of 2025, highlighting their key features, benefits, and essential considerations for prospective buyers.

Top CNC Lathe Machines in 2025: Features, Benefits, and Buying Guide

As we look toward 2025, the CNC lathe machine market is expected to evolve significantly, driven by advancements in technology and increasing demand for precision machining. According to a recent report by MarketsandMarkets, the global CNC lathe machine market is projected to reach USD 5.98 billion by 2025, growing at a CAGR of 6.5%. This growth is attributed to the rising adoption of automation in manufacturing processes, enhanced production efficiency, and the need for high-performance machining tools.

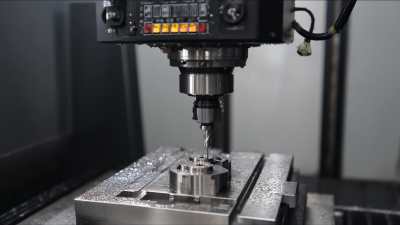

When considering the features of the top CNC lathe machines, buyers should prioritize cutting-edge technology like multi-axis capabilities, advanced spindle systems, and user-friendly interfaces. Machines equipped with high-speed spindles can significantly enhance productivity, while multi-axis controls allow for complex components to be machined in a single setup, reducing both work time and the need for multiple fixtures. Furthermore, connectivity features enabling remote operation and monitoring can lead to improved workflow and machine utilization.

**Tips:** Before making a purchasing decision, assess the specific machining requirements of your operations. Consider options that not only meet your immediate needs but also offer scalability for future demands. Additionally, evaluate the available after-sales support and training from the manufacturer to ensure your team can fully leverage the machine's capabilities. Investing in education and training can maximize the returns on your CNC lathe machine purchase.

Top CNC Lathe Machines in 2025: Features and Performance Comparison

Key Features of CNC Lathe Machines: Precision and Technology Advancements

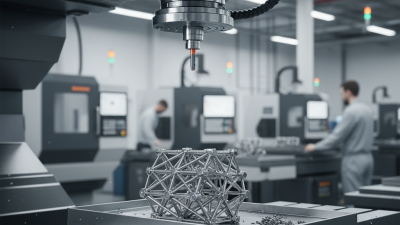

The evolution of CNC lathe machines has been driven by significant advancements in precision and technology. At the heart of contemporary CNC lathes is the integration of sophisticated control systems that enhance accuracy in machining. These systems allow operators to produce complex geometries and maintain tight tolerances, which are crucial for industries such as aerospace and automotive manufacturing. The latest CNC lathes also feature high-resolution encoders and feedback systems that ensure real-time monitoring of the machining process, reducing errors and improving overall efficiency.

Another key feature of modern CNC lathe machines is their adaptability to various materials. Advances in tooling technology and machine design now enable these machines to handle a broader range of materials, from soft metals to harder alloys. This versatility is further enhanced by the implementation of automated tool changers and advanced cooling systems, which improve productivity by minimizing downtime between operations. Furthermore, the incorporation of smart technology, such as IoT connectivity and data analytics, allows manufacturers to optimize their production processes, leading to more informed decision-making and improved outcomes in manufacturing workflows.

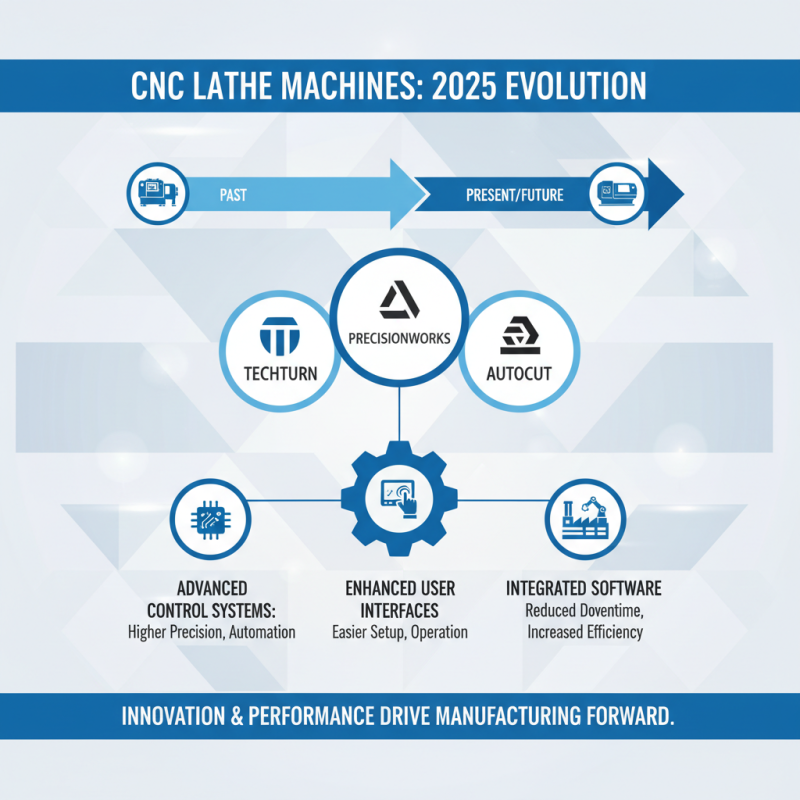

Comparative Analysis of Leading CNC Lathe Brands in 2025

In 2025, the landscape of CNC lathe machines continues to evolve, with multiple brands leading the charge in innovation and performance. A comparative analysis of these leading brands reveals distinct features and benefits that cater to varied manufacturing needs. Modern CNC lathes are defined by their advanced control systems, which allow for higher precision and automation. Enhanced user interfaces and integrated software solutions have made setup and operation easier, reducing downtime and increasing efficiency on the shop floor.

Moreover, durability and energy efficiency have become paramount for manufacturers looking to reduce operational costs. Many of the top machines now come equipped with features like coolant systems that optimize the machining process while minimizing waste. Additionally, certain models offer modular designs, allowing users to customize their machines based on specific applications. This kind of versatility is a significant advantage for businesses aiming to remain competitive in an ever-changing market. As industries increasingly embrace technology, understanding these nuances among CNC lathe brands becomes essential for making informed purchasing decisions.

Benefits of Investing in CNC Lathe Machines for Modern Manufacturing

Investing in CNC lathe machines can significantly enhance modern manufacturing processes. These advanced tools automate complex tasks that would otherwise require extensive manual labor, leading to increased precision and efficiency. By utilizing CNC technology, manufacturers can achieve tighter tolerances and uniformity in their products, which is crucial in today's competitive market. Moreover, CNC lathes enable the production of intricate designs and shapes that would be challenging to replicate by hand, thus broadening the scope of design possibilities.

Tips for choosing the right CNC lathe machine include assessing your specific manufacturing needs. Consider the materials you will be working with, the size of the components, and the complexity of the geometries involved. Additionally, ensure that the machine's software is compatible with your design tools, as streamlined workflows significantly enhance productivity. Another important factor is the level of support and training provided by the supplier; investing in quality training can help your team maximize the machine's capabilities.

Another benefit of CNC lathe machines is their ability to operate continuously with minimal supervision, which can drastically reduce labor costs. This automation allows skilled workers to focus on more critical aspects of production rather than repetitive tasks. Additionally, the data tracking capabilities of CNC machines can help in monitoring performance and identifying areas for improvement in production efficiency.

Top CNC Lathe Machines in 2025: Features, Benefits, and Buying Guide

| Model | Max Spindle Speed (RPM) | Swing Over Bed (mm) | Bed Length (mm) | Control System | Key Features | Estimated Price (USD) |

|---|---|---|---|---|---|---|

| Model A | 3000 | 400 | 1000 | Fanuc | Automatic Tool Change, High Precision | $45,000 |

| Model B | 4000 | 500 | 1200 | Siemens | Live Tooling, High Efficiency | $55,000 |

| Model C | 3500 | 450 | 1100 | Mitsubishi | Programmable RPM, Tool Wear Monitoring | $50,000 |

| Model D | 3200 | 480 | 1050 | Haas | User-Friendly Interface, High Speed Machining | $48,000 |

Essential Factors to Consider When Buying a CNC Lathe Machine

When purchasing a CNC lathe machine, several essential factors should guide your decision-making process. First, consider the machine's specifications, such as spindle speed, bed length, and maximum turning diameter. These specifications directly impact the type of work you can perform and the materials you’ll be able to work with. It’s crucial to choose a machine that fits your production needs and can handle the projects you typically undertake.

Another significant factor is the control system. A user-friendly and versatile control system increases productivity and minimizes the learning curve for operators. Make sure to explore different interfaces and programming options available, as they can greatly affect the efficiency of your machining processes.

Tips for selecting the right CNC lathe machine include evaluating the machine's build quality and durability. A robust construction will ensure longevity and stable operation, reducing downtime due to maintenance. Additionally, consider the availability of customer support and spare parts. A reliable support system can make a considerable difference in the lifespan and performance of your equipment. Don't hesitate to ask for demonstrations or check reviews from other users to ensure you’re making an informed investment.

Conclusion

In 2025, the landscape of CNC lathe machines is marked by significant advancements in precision and technology, positioning them as essential tools in modern manufacturing. Key features of these machines include enhanced automation, improved accuracy, and user-friendly interfaces that streamline the machining process. Investing in a CNC lathe machine not only increases productivity but also ensures higher quality output, making it a valuable addition for manufacturers looking to stay competitive.

When considering the purchase of a CNC lathe machine, prospective buyers should evaluate essential factors such as machine size, capabilities, and compatibility with existing systems. Furthermore, future trends point toward even more integration of smart technologies and automation, suggesting that the CNC lathe machine will continue to evolve to meet the growing demands of the industry. Keeping these considerations in mind will help ensure a sound investment in this vital manufacturing equipment.

Related Posts

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Benefits of Using a Large CNC Machine in Modern Manufacturing Processes

-

Top 10 CNC Machining Centers: Which One is Best for Your Needs?

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

10 Essential Tips for Achieving Precision CNC Machining Success

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections