Top 10 Swiss Lathe Applications in Modern Manufacturing Industry

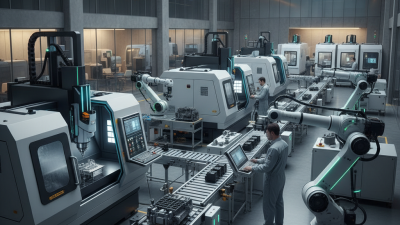

In the realm of modern manufacturing, the Swiss lathe stands out as a pivotal tool. Renowned expert Dr. Anna Schmidt notes, "Swiss lathes revolutionize precision engineering." This statement captures the essence of how these machines shape industries today.

Swiss lathes are known for their precision and efficiency. They excel in producing complex parts with tight tolerances. From medical devices to automotive components, their applications are vast. However, the upkeep and operation of Swiss lathes require skilled technicians. This demand for expertise can pose a challenge for some manufacturers.

Despite their advantages, reliance on Swiss lathes can lead to vulnerabilities in production. If a machine breaks down, entire workflows can be disrupted. Companies must be ready to adapt and find solutions quickly. Thus, the importance of understanding Swiss lathe applications cannot be overstated.

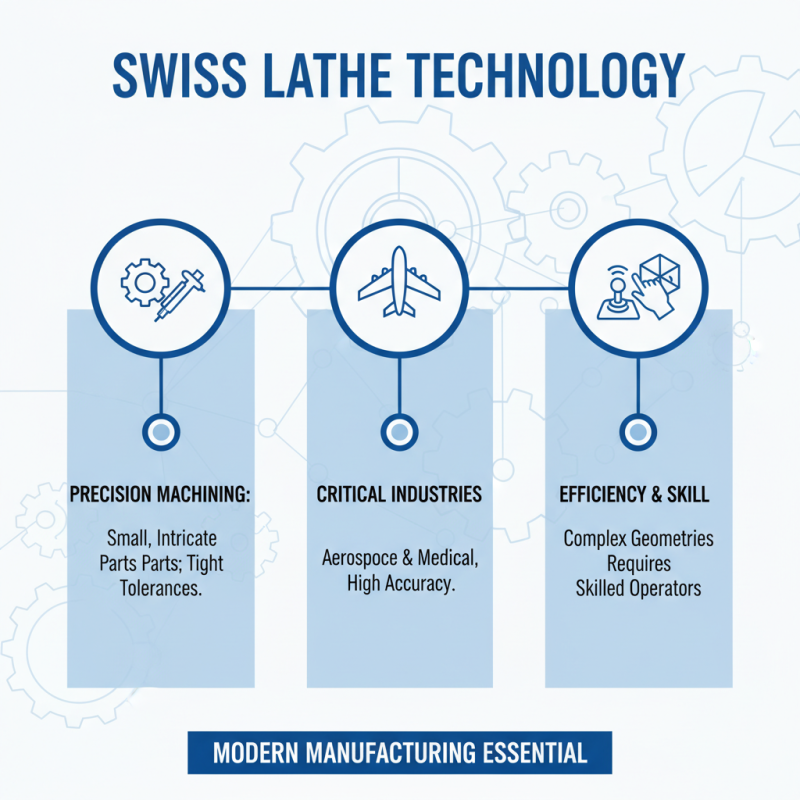

Understanding Swiss Lathe Technology in Manufacturing

Swiss lathe technology plays a crucial role in modern manufacturing. These machines excel in precision machining. They are designed to handle small, intricate parts with tight tolerances. This is vital for industries like aerospace and medical devices, where accuracy matters the most. Operators often appreciate the efficiency offered by Swiss lathes in producing complex geometries. However, mastering this technology requires skilled labor.

The unique design of Swiss lathes allows for continuous workpiece feeding. This reduces cycle times significantly. Still, setting up these machines can be challenging. It might take hours to prepare for production. Sometimes, even experienced operators make mistakes during setup. Such errors can lead to wasted materials and costly downtime.

Embracing Swiss lathe technology can transform a manufacturing facility. The ability to produce parts quickly and accurately is a game changer. Yet, businesses must invest in training their workforce. Continuous learning is essential, as the field constantly evolves. The future of manufacturing will surely lean more on innovations like Swiss lathes, but they also come with their own hurdles. Balancing speed with quality is an ongoing challenge.

Key Advantages of Using Swiss Lathes in Production

Swiss lathes are becoming essential in modern manufacturing. They offer precision and efficiency that traditional machines often lack. The key advantages include high accuracy and reduced cycle times. This makes them ideal for complicated parts. For instance, industries producing small, detailed components benefit most from Swiss lathes.

Tips for maximizing output: consider the setup time. A well-prepared workflow can eliminate delays. Streamlining the process means you keep up with demands. Also, ensure that operators are well-trained. Knowledge of machine capabilities can lead to better quality products.

Despite their benefits, there are challenges. Not every project suits a Swiss lathe perfectly. Complex geometries may require additional tooling. It’s important to weigh the costs of production against the advantages. A critical evaluation can identify when to choose a different manufacturing method. This kind of reflection can enhance decision-making in production strategies.

Top 10 Swiss Lathe Applications in Modern Manufacturing Industry

| Application | Key Advantages | Materials Used | Typical Industries |

|---|---|---|---|

| Medical Devices | High precision and cleanliness | Stainless Steel, Titanium | Healthcare, Biotech |

| Aerospace Components | Complex geometries and lightweight | Aluminum Alloys, Titanium | Aerospace |

| Automotive Parts | High volume production | Steel, Plastic | Automotive |

| Electronics | Small, intricate parts | Copper, Aluminum | Electronics |

| Hydraulic Components | Robust construction | Steel, Brass | Industrial Equipment |

| Watchmaking | Exceptional detail and precision | Gold, Silver, Stainless Steel | Luxury Goods |

| Optical Equipment | Precision shaping | Glass, Aluminum | Optics |

| Fasteners | Efficient production | Steel, Brass | Construction, Automotive |

| Defense Components | High durability | Alloy Steel | Defense |

| Robotics | Precision and versatility | Aluminum, Steel | Automation, Technology |

Top Industries Benefiting from Swiss Lathe Applications

Swiss lathes have transformed many sectors in the manufacturing industry. Aerospace is one of the key areas benefiting from their precision. These machines create complex components with tight tolerances. Parts like turbine blades require high reliability and precision. Any slight error can lead to catastrophic failures. This makes Swiss lathes an invaluable tool for manufacturers.

Medical device manufacturing also thrives due to Swiss lathe technology. Components used in surgical instruments demand exceptional accuracy. Even the slightest imperfection can affect patient outcomes. Additionally, the automotive industry relies on Swiss lathes for various intricate parts. From connectors to fasteners, these components are critical. However, quality control remains a challenge. Some manufacturers struggle to maintain consistency.

The electronics sector is another major beneficiary. Swiss lathes produce small, detailed parts for circuit boards. These components help in miniaturizing devices. While the benefits are clear, issues like setup time can hinder production. Manufacturers must continuously improve their processes. Exploring new methods may enhance efficiency and reduce waste.

Popular Swiss Lathe Techniques and Their Uses

Swiss lathes have transformed the manufacturing industry. Their precision and versatility make them ideal for various applications. Common techniques include sliding headstock machining and fixed headstock turning. Each method offers unique advantages, catering to diverse production needs.

Sliding headstock lathes excel in producing long, slender parts. This technique significantly reduces waste and enhances efficiency. Many manufacturers prefer this for small, complex components. In contrast, fixed headstock lathes are ideal for larger pieces. They provide robust stability, allowing for heavier cuts. This versatility is crucial in industries such as automotive or aerospace.

Tip: Always analyze your production requirements before choosing a lathe type. Consider factors like material, size, and complexity.

Another popular technique is multi-tasking. These machines can perform various operations, minimizing setup times. Operators save time and reduce labor costs. However, mastering these complex machines takes practice. Regular training is essential to avoid errors.

Tip: Document processes and maintain records of machine settings. This practice can help identify recurring issues and foster continuous improvement.

Using Swiss lathes can be a game-changer. However, investing in quality training is necessary for maximizing their potential and minimizing mistakes.

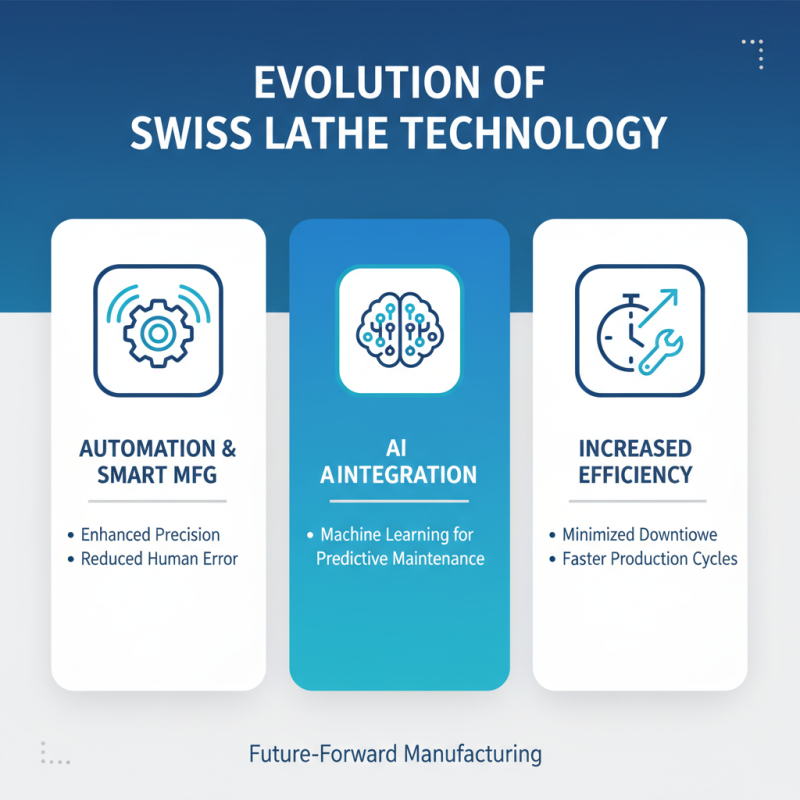

Future Trends in Swiss Lathe Technology and Applications

Swiss lathe technology is evolving rapidly. Manufacturers are now focusing on automation and smart manufacturing solutions. Integration of AI is becoming common. These advancements enhance precision and reduce human error. Machine learning algorithms can predict maintenance, which prevents downtime.

Customization is another trend shaping Swiss lathes. Customers increasingly demand tailored products. This leads to more complex designs and intricate components. However, adapting technology for these needs is challenging. Not all machines can handle intricate variations easily.

Sustainability is a growing concern too. Many companies seek eco-friendly manufacturing practices. They aim to minimize waste and energy consumption. Implementing these practices requires investment and commitment. The transition may not be seamless. Overall, the future of Swiss lathe technology promises exciting developments and persistent challenges.

Related Posts

-

Top 10 Benefits of Using CNC Turning Machines for Precision Manufacturing

-

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

-

What is Manufacturing Machines and How They Transform Production Processes

-

Why CNC Machining Parts Are Essential for Modern Manufacturing Efficiency: Industry Insights & Data

-

Understanding CNC Controllers: Revolutionizing Precision Manufacturing with 30% Higher Efficiency