The ZEISS SURFCOM 130—a legacy surface finish tester that was once a staple in precision…

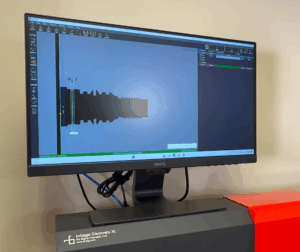

When you’re measuring small turned parts, accuracy, repeatability, and ease of use aren’t optional—they’re essential. That’s why Concept Advanced Manufacturing Solutions relies on the Six Sigma Discovery system to get the job done right.

Whether you’re checking diameters, thread pitch, or GD&T features like flatness, the Six Sigma Discovery offers intuitive tools, powerful optics, and 360° rotary inspection that make measuring both fast and precise.

Why the Six Sigma Discovery?

In our video, Nadine, one of Concept’s Application Engineers, walks us through why this system is effective for turned part measurement:

“The Six Sigma Discovery is perfect for small parts, thanks to its excellent magnification and flexible measuring tools,” she says.

Let’s break down what she means.

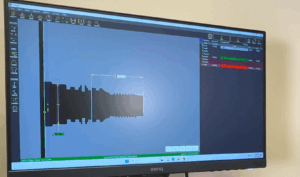

Simple Measurement Interface

All measurement tools are located along the left side of the screen for quick access. Quickly check diameter, distances, and more.

How To Check A Diameter On The Six Sigma Discovery:

- Select the Vernier tool

- Draw a box around your feature

- Right-click to enter the nominal size and tolerances from your print

- Instantly see if the part is within spec (green = good)

“You get a clear visual pass/fail result—it couldn’t be easier,” Nadine adds.

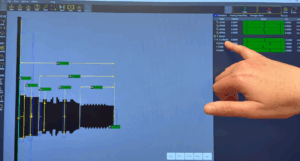

How To Check Distance & Dimensional Measurements on the Six Sigma Discovery

Need to measure a length or spacing between two features?

Need to measure a length or spacing between two features?

1. Create two edges using the Edge Tool

2. Select the Dimension Tool

3. Choose the edges to compare

4. Right-click again to apply tolerances based on your blueprint

Thanks to the rotary functionality, the Six Sigma Discovery can evaluate diameters all the way around the part—360°, offering far more precision than traditional two-point caliper methods.

Flatness and GD&T Inspection

In addition to basic measurements, the system isn’t just for basic checks. It can also handle common GD&T callouts like flatness, which is critical for many turned components.

Need Thread Measurement? No Problem

Moreover, the Discovery can automatically detect and measure threads.

Simply:

- Select the Thread Tool

- Draw a box around the thread

- Let the system recognize the pitch and form

As a result, it’s ideal for applications where thread quality is mission-critical.

Perfect for Precision Machining and Small Parts

Whether you’re in aerospace, medical, or general manufacturing, this system offers the clarity and control needed for small, high-tolerance parts.

“Even our tiniest features are easy to inspect with this system,” says Nadine.

Watch the Full Demo

Want to see the Six Sigma Discovery in action? Watch Nadine’s full walk-through of the Six Sigma Discovery system to see how simple, fast, and powerful this inspection tool really is.